- بيت

- صناعة الزجاج

صناعة الزجاج

حل

مقدمة لفرن الزجاج

فرن الزجاج هو نوع من المعدات المستخدمة خصيصًا لتصنيع الزجاج. وعادة ما يتكون من جسم الفرن, الموقد, نظام التحكم في درجة الحرارة, جهاز النقل ومخرج المنتج الزجاجي. يشتمل الجزء الداخلي لجسم الفرن أيضًا على الطبقة العازلة, غرفة الاحتراق, تجمع زجاجي وأجزاء أخرى. تعتبر المواد المقاومة للحرارة مكونًا مهمًا في فرن صهر الزجاج. أنها تلعب دورا حاسما في جودة الزجاج, استهلاك الطاقة وتكلفة المنتج.

تصنيف أفران الزجاج

- ال فرن الزجاج المقسى هو فرن يقوم بتسخين الزجاج المسطح العادي أو الزجاج الرقائقي عند درجة حرارة معينة, ومن ثم يستخدم التبريد القسري لجلب السطح الزجاجي إلى حالة من الضغط الانضغاطي. يتميز الزجاج المعالج بواسطة فرن الزجاج المقسى بخصائص قوة الضغط العالية والجزيئات الصغيرة بعد الكسر. لديها سلامة عالية ومجموعة واسعة من التطبيقات. يتميز فرن الزجاج المقسى بالتحكم الدقيق في درجة الحرارة وكفاءة الإنتاج العالية.

- فرن زجاجي عائم هي قطعة من المعدات المستخدمة لإنتاج الزجاج المسطح. يتم تسخين المادة الخام الزجاجية إلى حالة طرية, تطفو على حمام من الصفيح ثم تبرد لتتشكل. يجب أن تتم عملية إنتاج الزجاج المصقول عند درجة حرارة عالية وتتميز بخصائص كفاءة الإنتاج العالية, سرعة الإنتاج السريعة وجودة المنتج الزجاجي الموحدة.

تكوين هيكل فرن الزجاج

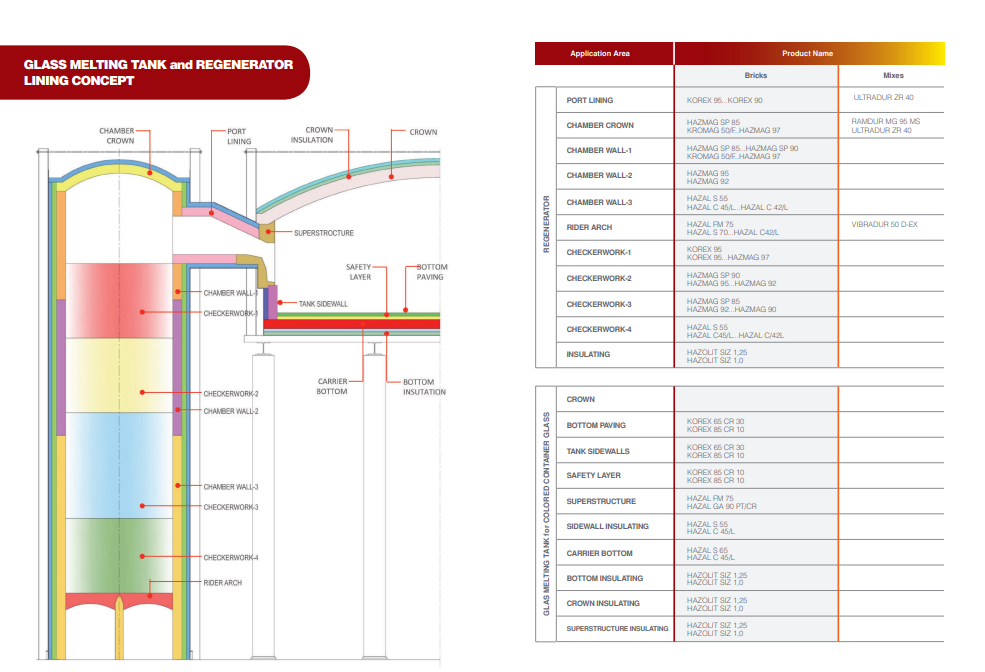

المكونات الرئيسية لفرن الزجاج تشمل غرفة تخزين الحرارة, الطوب المدقق, جدار تقسيم الهواء والنار, الطوب العازل, إلخ. غرفة تخزين الحرارة عبارة عن معدات دورية للتبادل الحراري, الذي ينتمي إلى مجال درجة الحرارة الدورية غير المستقرة, وعملية نقل الحرارة هي نقل حرارة غير مستقر. يعتبر الطوب المدقق هو المكون الأساسي لغرفة تخزين الحرارة, المسؤولة عن تخزين وإطلاق الحرارة. جدار تقسيم الهواء والنار هو جدار التقسيم بين غرفة تخزين حرارة الهواء وغرفة تخزين حرارة الغاز. لأن درجة الحرارة العلوية مرتفعة جداً ويحدث تآكل للمواد المتطايرة, فمن السهل اختراق النار بعد الاحتراق, لذا فإن سمكها كبير بشكل عام ويتطلب أعمال بناء صارمة. يستخدم الطوب العازل لتقليل فقدان الحرارة للجدار الخارجي لغرفة تخزين الحرارة.

مبدأ عمل فرن الزجاج

مبدأ العمل للفرن الزجاجي يشمل بشكل رئيسي نقل الحرارة, نقل الزخم ونقل الكتلة. يشمل نقل الحرارة التبادل الحراري في مساحة اللهب الناتج عن اختلاف درجة الحرارة في مساحة اللهب وفي السائل الزجاجي, التبادل الحراري في السائل الزجاجي, التبادل الحراري في غرفة تخزين الحرارة, والتبادل الحراري بين جدار الفرن والبيئة الخارجية. يحدث نقل الزخم بسبب اختلاف الضغط, وينطوي النقل الجماعي على تفاعلات كيميائية وتغييرات في تركيب السائل الزجاجي.

الأخطاء والحلول الشائعة لفرن الزجاج

1. لا يوجد تفريغ من رأس الفرن

سبب

درجة حرارة الفرن منخفضة جدًا

درجة الحرارة عند مخرج حلق الفرن منخفضة

الكثير من الخبث يسبب الانسداد

حل

زيادة إمدادات الوقود وزيادة درجة حرارة الفرن

ضبط وقت الاحتراق والمساحة, تحسين ظروف التوجيه الجوي, وزيادة درجة حرارة مخرج الحلق الفرن

تنظيف الخبث, ضبط نسبة المواد الخام, والحد من توليد الخبث

2. ضرر الفرن

سبب

التآكل الكيميائي: السائل الزجاجي غني بالسيليكا, الذي يسبب تآكلًا كيميائيًا خطيرًا على مادة بطانة الفرن

التجريف الميكانيكي: تنظيف قوي لتدفق السائل الزجاجي والمواد

تأثير ارتفاع درجة الحرارة: درجة حرارة العمل لحوض الفرن مرتفعة 1600 درجات, وتتقلب درجة حرارة كل جزء بشكل كبير

حل

اختر المواد المقاومة للحرارة والتي يمكنها مقاومة التآكل, مثل سلسلة AL2O3ZrO2-SiO2 من الطوب المنصهر

اختر مواد حرارية عالية القوة ومقاومة للتآكل

مواد مقاومة للتآكل الناتج عن درجات الحرارة العالية ولا تلوث السائل الزجاجي

3. مشاكل مع عملية نزع النتروجين SCR في الأفران

الأسباب

تدهور أداء المحفز

مشاكل إمدادات الأمونيا

صعوبة صيانة المعدات

مشاكل معالجة مياه الصرف الصحي

الحلول

استبدل المحفزات بانتظام, تحسين ظروف التشغيل, واستخدام عوامل التنظيف الخاصة

تحسين أنظمة تخزين ونقل الأمونيا, وتطوير مصادر جديدة للأمونيا

استخدم مواد وتصميمات أكثر متانة, وتوفير التدريب على الصيانة المهنية

استخدام تقنيات معالجة مياه الصرف الصحي المتقدمة مثل التناضح العكسي أو التبخر

4. فشل الفرن المشترك الآخر

الأسباب والحلول

| ظاهرة الخلل | سبب | حل |

|---|---|---|

| خطأ كبير في مؤشر درجة الحرارة | يتم حظر المزدوجة الحرارية أو حرقها بواسطة المواد | قم بتنظيف المواد المتراكمة أو استبدل المزدوجة الحرارية |

| مؤشر الضغط منخفض | أنبوب قياس الضغط مسدود بالغبار أو الإعصار مملوء بالمواد. | استخدم الهواء المضغوط لتفجير مقياس الضغط أو مخروط الإعصار |

| تشغيل المواد الخام | تنخفض درجة الحرارة في ذيل الفرن كثيرًا, كمية تغذية الفحم قليلة جدًا, إلخ. | تقليل الأعلاف, تقليل سرعة الفرن, أضف الفحم بشكل مناسب |

ما هو المنبه الذي يجب ضبطه لنظام حماية تبريد الهواء في الفرن الزجاجي

- جهاز إنذار لدرجة الحرارة: أثناء عملية إنتاج أفران الزجاج, قد تكون درجة الحرارة مرتفعة جدًا بسبب تأثير البيئة. من أجل تجنب تلف المعدات ومشاكل سلامة الإنتاج الناجمة عن درجة حرارة الفرن المفرطة, يجب ضبط جهاز إنذار لدرجة الحرارة. بمجرد أن تتجاوز درجة حرارة الفرن القيمة المحددة, يمكن إصدار إنذار في الوقت المناسب.

- مراقب تدفق الهواء: أثناء عملية الإنتاج, تولي أفران الزجاج اهتمامًا كبيرًا للتحكم في تدفق الهواء وتنظيمه. إذا كان تدفق الهواء غير كاف, المواد الخام الزجاجية لا تذوب بالكامل. مطلوب كمية كبيرة من الهواء للحفاظ على فرن الزجاج يعمل لفترة طويلة. يمكن لجهاز مراقبة تدفق الهواء مراقبة حجم الهواء والتحكم فيه. بمجرد وجود مشكلة في تدفق الهواء, سيتم إصدار إنذار.

- كاشف الأوكسجين: أثناء عملية إنتاج الزجاج, يتطلب احتراق الغاز في الفرن كمية معينة من الأكسجين. إذا كان الأكسجين غير كاف, سيؤدي إلى مشاكل مثل انخفاض إنتاج الزجاج وانخفاض الجودة. لذلك, يجب تركيب كاشف الأكسجين لمراقبة تركيز الأكسجين في الوقت الفعلي وإصدار إنذار في الوقت المناسب.