وصف

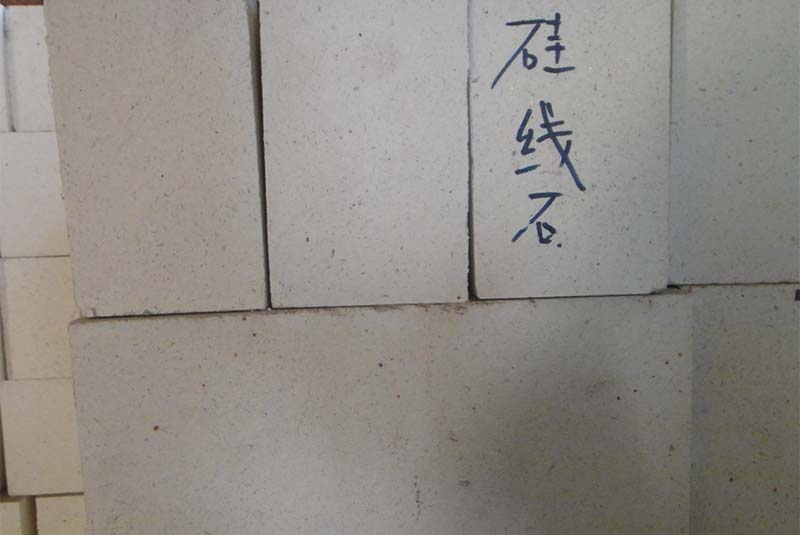

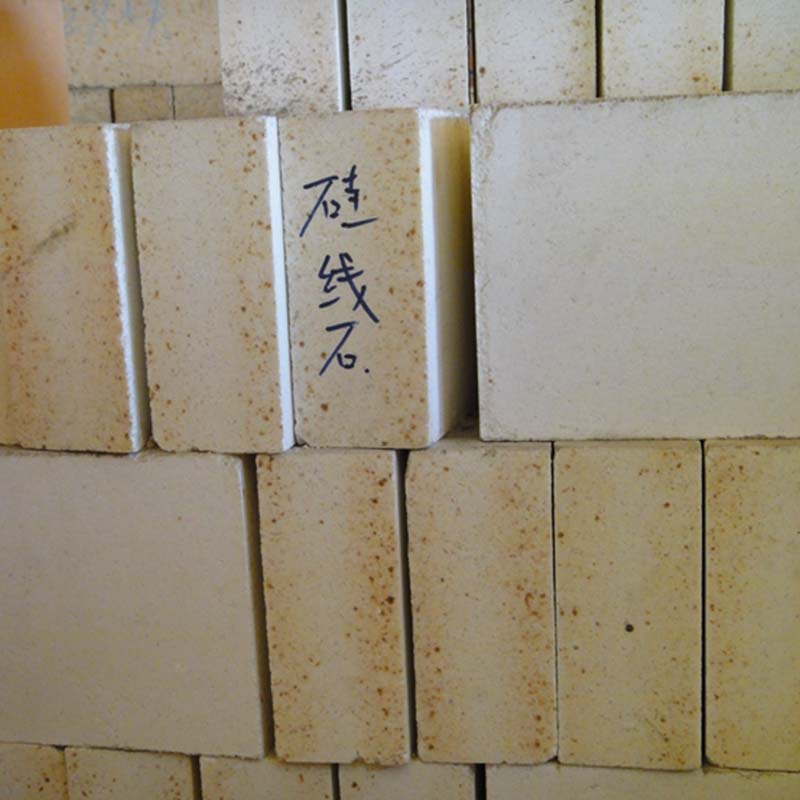

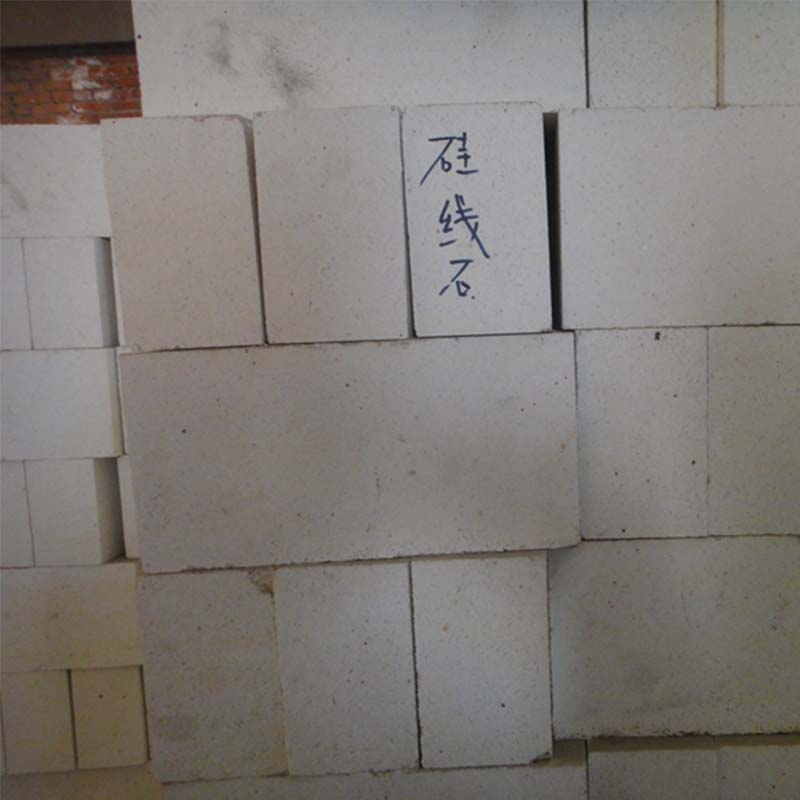

What are sillimanite bricks?

Sillimanite bricks are natural sillimanite products made with sillimanite as the main raw material or one of the main raw materials. They have been widely used as working pool wall bricks, material channel bricks, and refractory parts such as feeder parts and rotating tubes in glass pool kilns. They are also used as kiln furniture for ceramic kilns and low creep hot blast furnace bricks, which have also received good results.

sillimanite bricks specification

| التركيب الكيميائي | Al2O3≥50%,SiO2≤45%,Fe2O3≤1.2% |

| المسامية الظاهرة | ≤18% |

| Body density(g/cm³) | ≥2.4 |

| Cold pressing strength(Mpa) | ≥45 |

| Softening temperature under load (0.2MPa, 0.6درجه مئوية) | ≥1550℃ |

| Reburning line change rate(1500درجه مئوية, 2h%) | ±0.1% |

| استقرار الصدمة الحرارية(100℃水次) | ≥20 Second-rate |

| Reversible thermal expansion(1000درجه مئوية) | 0.55%~0.6% |

| Temperature melting cone equivalent(S.C.SK) | 35~38 |

من ويكيبيديا: Fire brick

Production method of sillimanite refractory bricks

Sillimanite bricks are refractory bricks with good properties made from sillimanite minerals by high-temperature sintering or slurry casting.

1-High-temperature sintering method

High-temperature sintering method is a traditional refractory material production method. It calcines sillimanite minerals at high temperatures to cause phase change, transforming them into mullite and free silica. This method can improve the refractoriness and stability of refractory bricks, and the refractoriness can usually reach 1770-1830℃.

2-Slurry casting method

Slurry casting method is a more modern production method. It mixes finely ground sillimanite minerals with binders into a slurry state and then pours it into a mold for molding. This method can produce refractory bricks with complex shapes and high density, which are suitable for specific industrial kilns.

سعر الطوب السليمانيت

mullite bricks vs sillimanite bricks

الطوب الموليت and sillimanite bricks are both high-alumina refractory materials, but they have significant differences in composition and performance. Mullite bricks are mainly composed of mullite (3Al₂O₃·2SiO₂) and have high refractoriness, low thermal conductivity and good thermal shock resistance. Sillimanite bricks are mainly made of sillimanite (Al₂SiO₅). Sillimanite will transform into mullite and silica at high temperatures, which enhances the strength of the brick. Mullite bricks are suitable for applications where high temperature stability is required, while sillimanite bricks are more suitable for applications that require structural reinforcement and thermal shock resistance.

Main uses of sillimanite refractory bricks

- فرن صهر الزجاج: used for key parts such as the molding of flow holes.

- فرن الانفجار: including furnace bottom protection bricks, furnace throat linings and tuyere combination bricks, إلخ.

- صناعة السيراميك: used as kiln furniture material.

التعليقات

لا توجد تعليقات حتى الآن.