বর্ণনা

What is a cordierite Support?

Cordierite Support refers to a bracket structure made of cordierite material. Cordierite is a magnesium aluminum silicate mineral with a low thermal expansion coefficient, good thermal shock resistance and fire resistance. These characteristics make cordierite an ideal material for manufacturing brackets used in high temperature environments. It is mainly used in refractory materials, electronic packaging materials, catalyst carriers, foam ceramics, printed circuit boards and low-temperature thermal radiation materials.

অন্যান্য ভাটা আসবাবপত্র

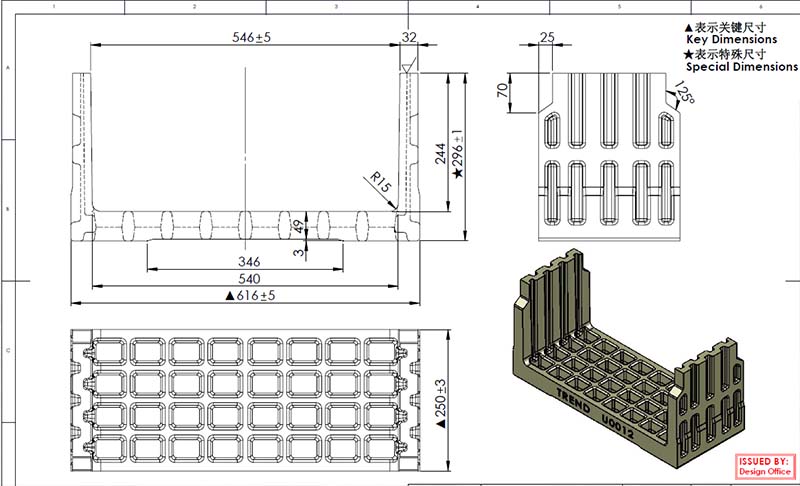

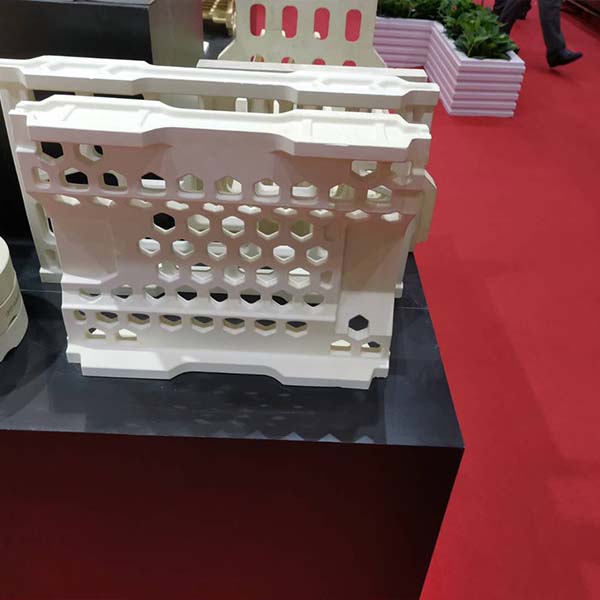

Cordierite Support design

Physical and chemical indicators of cordierite Supports

| শারীরিক এবং রাসায়নিক সূচক | Numerical range | Remark |

|---|---|---|

| রাসায়নিক রচনা | MgO: 13.8%, Al2O3: 35.2%, SiO2: 51% | Standard chemical composition of synthetic cordierite |

| Coefficient of thermal expansion | (1.4-1.6)×10^-6/°C | নিম্ন তাপ সম্প্রসারণ সহগ, which helps to improve the stability and durability of the material |

| তাপ পরিবাহিতা | about 1.5W/(m·K) | নিম্ন তাপ পরিবাহিতা, suitable for use as insulation material |

| তাপীয় শক প্রতিরোধের | ভাল | Able to withstand large temperature changes without breaking |

| Dielectric constant | সম্পর্কে 5 | Low dielectric constant, suitable for use as insulating material |

| Dielectric loss | low | Low dielectric loss, improving energy efficiency |

| রাসায়নিক স্থিতিশীলতা | ভাল | Acid and alkali corrosion resistant, suitable for a variety of chemical environments |

| ঘনত্ব | 2.53~2.78g/cm³ | Moderate density, easy to process and use |

| মোহস কঠোরতা | 7~7.5 | Higher hardness, wear resistance |

| গলনাঙ্ক | 1460°সে | উচ্চ গলনাঙ্ক, উচ্চ তাপমাত্রা প্রতিরোধের |

Characteristics and advantages of cordierite brackets

- নিম্ন তাপ সম্প্রসারণ সহগ: Cordierite has a low thermal expansion coefficient, which means that the size of the cordierite bracket changes less when the temperature changes, and it can maintain good dimensional stability.

- High strength and fire resistance: Although the density of the cordierite bracket is relatively low (2.53~2.78g/cm³), it has a high Mohs hardness (7.0~7.5) and a melting point of 1460℃, which allows it to maintain good mechanical strength and fire resistance in high temperature environments.

- Good seismic resistance: The seismic resistance of cordierite Supports is good, and they can resist vibration and impact to a certain extent, which is especially important for brackets used in environments such as industrial kilns.

- উচ্চ তাপমাত্রা পরিবেশের জন্য উপযুক্ত: Due to these characteristics of cordierite, it is particularly suitable for manufacturing Supports that need to work in high temperature environments, such as ceramic kiln sheds, saggers, ইত্যাদি.

Cordierite Support price

Manufacturing process of cordierite brackets

The manufacturing process of cordierite Supports mainly includes several key steps: selection of raw materials, ছাঁচনির্মাণ, firing and post-processing.

First, high-purity cordierite ore must be strictly screened to ensure the quality of the final product. Then, the raw materials are processed into the required shape through pressing or mold forming technology.

Subsequently, the bracket is fired at high temperature to ensure its structural stability and high temperature resistance.

Finally, surface treatment and quality inspection are carried out to meet the use requirements and aesthetic effects.

The overall process requirements are rigorous to ensure the reliability and durability of cordierite brackets in various applications.

Comparison of cordierite Supports with other materials

Comparison of physical properties

| nature | cordierite | Other materials (such as alumina, mullite) |

|---|---|---|

| Coefficient of thermal expansion | Low | উচ্চতর |

| তাপ পরিবাহিতা | Low | উচ্চতর |

| অপারেটিং তাপমাত্রা | উচ্চ | Lower |

| তাপীয় শক প্রতিরোধের | শক্তিশালী | Weaker |

Comparison of chemical properties

| nature | cordierite | Other materials (যেমন. অ্যালুমিনা, mullite) |

|---|---|---|

| রাসায়নিক স্থিতিশীলতা | উচ্চ | lower |

| জারা প্রতিরোধের | strong | weaker |

Economic Comparison

| nature | cordierite | Other materials (যেমন. অ্যালুমিনা, mullite) |

|---|---|---|

| খরচ | medium | Lower or higher |

| Preparation difficulty | medium | Easier or harder |

Application field comparison

| আবেদন এলাকা | cordierite | Other materials (যেমন. অ্যালুমিনা, mullite) |

|---|---|---|

| Automobile exhaust purification | চমৎকার | ভাল |

| Ceramic catalyst carrier | চমৎকার | ভাল |

| High temperature structural materials | চমৎকার | ভাল |

Application areas of cordierite Supports

| আবেদন এলাকা | Detailed description |

|---|---|

| অবাধ্য উপকরণ | Due to its low thermal expansion coefficient and good high-temperature thermal shock resistance, cordierite supports are often used to make tunnel kiln shed plates and support materials. They can significantly shorten the production cycle and can be used directly on flames. Lightweight cordierite materials have High efficiency and energy saving effect. |

| Ceramic catalyst carrier | Cordierite’s low expansion coefficient and good adsorption properties can be used to make catalyst carriers for automobile exhaust purification, helping the catalyst to better adsorb and disperse on the carrier and quickly reach the activation temperature. |

| Honeycomb ceramics | Cordierite honeycomb ceramics are mainly used in automobile combustion gas channels to absorb exhaust gas heat in the exhaust channel and transfer it to other heat recovery devices in the form of heat radiation. |

| Electronic packaging materials | Cordierite supports are also used in electronic packaging materials, especially where good thermal management and electrical insulation are required. |

| Foam ceramic | The porous structure and low thermal expansion coefficient of cordierite can be used to produce foam ceramics, which are suitable for chemical processing such as high-temperature flue gas filtration and catalytic combustion. |

Cordierite Support Shipping Packaging

আমাদের অন্যান্য ওয়েবসাইট:https://www.lite-kilnrefractory.com/

রিভিউ

এখনও কোন পর্যালোচনা নেই.