বর্ণনা

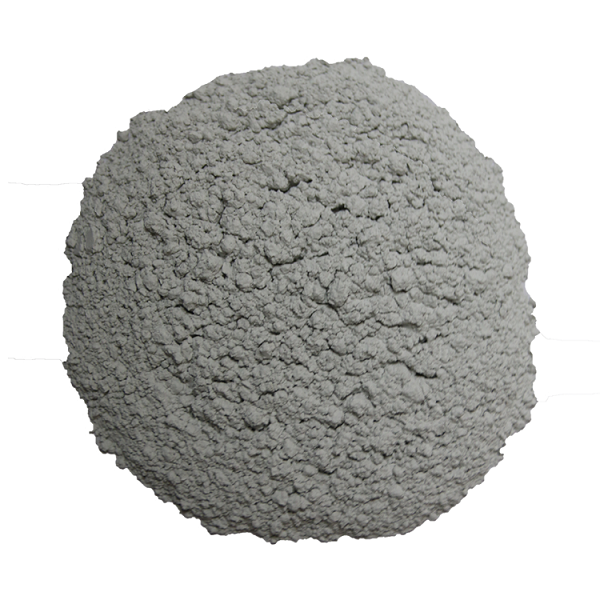

Refractory cement Description

Refractory cement is made of high-quality bauxite and lime as raw materials, and is mixed into raw materials with appropriate ingredients in a certain proportion. After sintering, the clinker with aluminate as the main component is ground into fine powder to make a refractory hydraulic cementitious material. Usually mixed with refractory cement

Other unshaped products

- অবাধ্য castable

- রামিং অবাধ্য

- Refractory plastic

- অবাধ্য মর্টার

- Refractory aggregate

- অবাধ্য বক্সাইট

- magnesium gunning material

টিechnical Parameter

| Item | CA-50 Cement | CA-60 Cement | CA-70 Cement | CA-80 Cement | |

| Chemical compoent | AL2O3% | 50-60 | 60-68 | 68-77 | 77 |

| SIO2 /% | 8.0 | 5.0 | 1.0 | 0.5 | |

| FE2O3/% | 2.5 | 2.0 | 0.7 | 0.5 | |

| R2O(Na2o+0.658K20)/% | 0.4 | 0.4 | 0.4 | 0.4 | |

| Rupture strength(এমপিএ) | 1day | 5.5 | 2.5 | 5.0 | 4.0 |

| 3দিন | 6.5 | 5.0 | 6.0 | 5.0 | |

| 28দিন | / | 10.0 | / | / | |

| কম্প্রেসিভ শক্তি(এমপিএ) | 1day | 40 | 20 | 30 | 25 |

| 3day | 50 | 45 | 40 | 30 | |

| 28দিন | / | 80 | / | / | |

| Setting time (Min) | Initial time | 30 | 60 | 30 | 30 |

| Final time | 360 | 1080 | 360 | 360 | |

Production process of refractory cement

ক[Raw material procurement] –> B[কাঁচামাল প্রস্তুতি] –> গ[উপাদান] –> D[mix] –> E[Grinding] –> F[Firing] –> জি[cool down] –> H[Crushing] –> আমি[filter] –> J[প্যাকেজ] –> K[Finished Product] –> এল[store] –> M[transportation]

- Raw material procurement: procurement of raw materials such as high alumina cement, refractory aggregate, fine aggregate, additives, ইত্যাদি.

- কাঁচামাল প্রস্তুতি: pre-process the raw materials, such as screening, cleaning, শুকানো, ইত্যাদি.

- ব্যাচিং: Accurately weigh various raw materials according to the recipe ratio.

- মেশানো: Mix the weighed materials evenly.

- Grinding: Grind the mixed materials into fine powder to increase the reaction area.

- Firing: sintering at high temperature to make the material undergo chemical reaction and form the crystal structure of refractory cement.

- কুলিং: The sintered material needs to be cooled to room temperature.

- Crushing: The cooled material is crushed into fine powder.

- Screening: Screening is used to ensure that the particle size meets the requirements.

- Packaging: Pack qualified products and prepare them for sale or storage.

- Finished product: The final refractory cement product.

- Storage: The product should be stored in a dry and ventilated warehouse.

- Transportation: Transport products to customers according to order requirements.

3000 Degree castable refractory cement

Refractory cement VS refractory mortar

অবাধ্য সিমেন্ট:

- রচনা: Mainly composed of aluminate cement, high alumina cement or other cement with good refractory properties, and some refractory aggregates may be added.

- আবেদন: Usually used in places where high temperature resistance is required, such as boilers, furnaces, চিমনি, ইত্যাদি. Can be used for pouring or spraying.

- বৈশিষ্ট্য:

- উচ্চ তাপমাত্রা প্রতিরোধের (usually over 1000°C).

- Fast solidification.

- High strength and high compressive strength.

- Good chemical resistance.

- Usage restrictions: Due to its high cost, it is usually used in critical areas or where quick repairs are required.

অবাধ্য সিমেন্ট

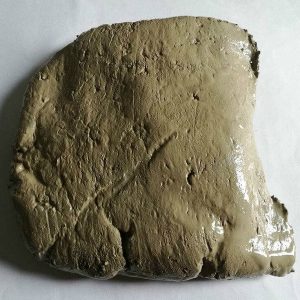

অবাধ্য মর্টার:

- রচনা: It is mainly composed of refractory materials (such as refractory clay, aluminum silicate, ইত্যাদি) mixed with cement or other binders. Different proportions can meet different refractory requirements.

- আবেদন: Mainly used for the joints between refractory bricks, refractory boards and other materials, and can also be used for refractory coatings.

- বৈশিষ্ট্য:

- The fire resistance can reach different temperatures according to the formula, but it is usually not as high as refractory cement.

- Strong bonding strength, suitable for masonry work.

- Easy construction, good fluidity, easy to fill gaps.

- Relatively poor chemical resistance.

- Usage restrictions: Due to its adhesiveness and fluidity, it is suitable for relatively low temperature environments or as an auxiliary material.

- Refractory cement is more suitable for structural parts that require high strength and high temperature resistance, such as the casting inside the furnace body.

- Refractory mortar is mainly used for masonry and filling gaps to provide bonding between materials.

Refractory Cement 25kg

Refractory cement uses

- High-temperature furnaces: used for lining, masonry and repair of furnaces

- Metallurgy: used for lining and repair of smelting furnaces, converters, electric furnaces and other equipment

- Chemical industry: used for lining and repair of chemical, storage tanks, pipelines and other equipment

- Construction industry: used for buildings in high-temperature environments, যেমন ব্লাস্ট ফার্নেস, বৈদ্যুতিক চুল্লি, steel mills, aluminum plants, ইত্যাদি.

- Electric power industry: used to manufacture bacon, boilers and burners, ইত্যাদি.

রিভিউ

এখনও কোন পর্যালোচনা নেই.