Beschreibung

Was ist ein AZS-Block??

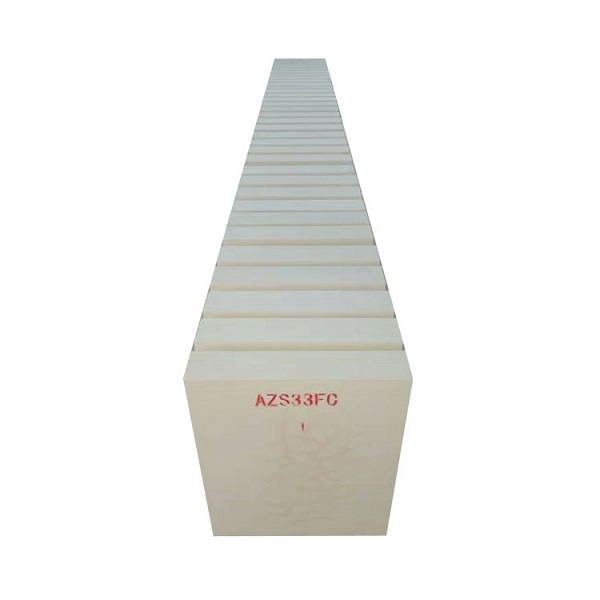

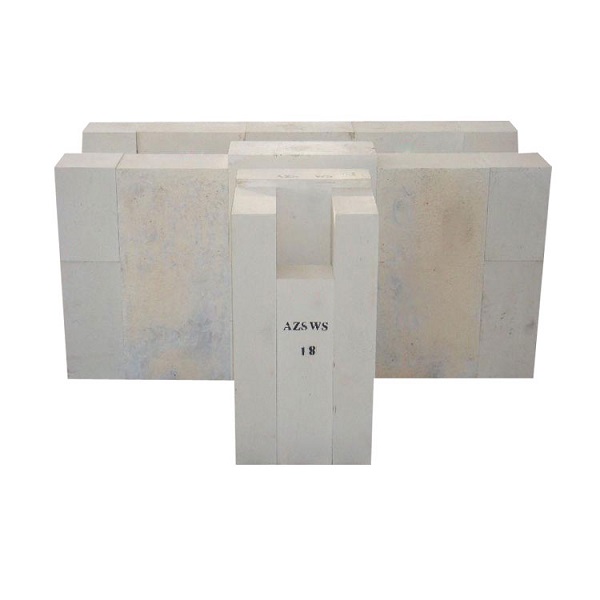

AZS Ziegel (Aluminiumoxid-Zirkonoxid-Silikat-Ziegel) ist ein hochleistungsfähiges Feuerfestmaterial, besteht hauptsächlich aus Aluminiumoxid, Zirkonoxid und Siliziumdioxid. Zu seinen Hauptvorteilen gehört die extrem hohe Feuerfestigkeit, Erosionsbeständigkeit und gute Thermoschockbeständigkeit, Geeignet für wichtige Teile von Glasschmelzöfen, wie Poolwände, Beckenböden und schmelzende Teile. AZS-Steine können der Erosion von Glasflüssigkeit wirksam widerstehen, verlängern die Lebensdauer des Ofenkörpers und senken die Wartungskosten. Aufgrund seiner Verschleißfestigkeit und mechanischen Festigkeit ist es auch in Industrieumgebungen mit hohen Temperaturen weit verbreitet.

Andere beliebte feuerfeste Steine

- Feuerfeste Ankerstein

- Feuerfeste Siliziumkarbidsteine

- Kieselstein

- Magnesia-Kohlenstoffstein

- Magnesia -Chromziegel

Technischer Parameter

| Artikel | AZS-33 | AZS-36 | AZS-41 |

| ZRO2 % | 32~36 | 35~40 | 40~44 |

| Al2O3 % | bleiben | bleiben | ≥50-60 |

| SiO2 % | ≤15,3 | ≤13 | ≤12,5 |

| Fe2O3 +TiO2+CaO+Na2O | ≤2,5 | ≤2,5 | ≤2,5 |

| Blasenbildungstendenz(1300℃ 36 Std,gewöhnliches Glas)% | ≤2,0 | ≤1,4 | ≤1,0 |

| Schüttdichte g/cm3 | ≤3,45 | ≤3,5 | ≤3,55 |

Aus Wikipedia:Feuerfest

Was sind die Inhaltsstoffe von AZS-Steinen??

Der Hauptbestandteil der feuerfesten AZS-Steine ist Al2O3 (Aluminiumoxid), ZRO2 (Zirkonoxid) und SiO2 (Siliziumdioxid).

Feuerfeste AZS-Steine werden auch als geschmolzene feuerfeste Steine bezeichnet, und werden auch als geschmolzene Zirkonkorundsteine bezeichnet. Die englische Abkürzung AZS steht hauptsächlich für die Anfangsbuchstaben der Hauptelemente Al2O3, ZRO2, und SiO2. Die Reihenfolge der Anordnung richtet sich nach dem Inhalt der Elemente, darunter liegt der Gehalt an Aluminiumoxid 48%, der Gehalt an Chromoxid beträgt ca 30%, und der Gehalt an Siliziumdioxid beträgt im Allgemeinen ca 20%.

Glasofen Azs Ziegel

Unterschiede zwischen Dolomitsteinen und AZS-Steinen

- Zusammensetzung: Dolomitsteine bestehen hauptsächlich aus Calciumcarbonat und Magnesiumcarbonat, während AZS-Steine aus Aluminiumoxid bestehen, Zirkonoxid und Siliziumdioxid.

- Anwendungsgebiete: Dolomitsteine werden vor allem in der Stahl- und Zementindustrie verwendet, während AZS-Steine hauptsächlich in der Glasindustrie verwendet werden.

- Leistung: Im Hinblick auf die Feuerbeständigkeit sind AZS-Steine den Dolomitsteinen im Allgemeinen überlegen, Erosionsbeständigkeit und Thermoschockbeständigkeit, Dolomitsteine sind jedoch kostengünstiger und für bestimmte Umgebungen mit hohen Temperaturen geeignet.

Wofür werden AZS-Steine verwendet??

- Glasschmelzofen: AZS-Steine werden hauptsächlich in wichtigen Teilen von Glasschmelzöfen verwendet, wie Poolwände, Beckenböden und schmelzende Teile. Seine hohe Feuerbeständigkeit und Erosionsbeständigkeit können der Erosion von Glasflüssigkeit wirksam widerstehen und die Lebensdauer des Ofenkörpers verlängern.

- Thermoschockbeständigkeit: AZS-Steine haben eine gute Temperaturwechselbeständigkeit und können häufigen Temperaturwechseln während des Betriebs von Glasschmelzöfen standhalten, Reduzierung von Strukturschäden durch Thermoschock.

- Verschleißfestigkeit: Aufgrund seiner hohen mechanischen Festigkeit und Verschleißfestigkeit, AZS-Steine reduzieren die Wartungs- und Austauschhäufigkeit, die durch mechanischen Verschleiß während des Glasherstellungsprozesses verursacht wird, Reduzierung der Produktionskosten.

Azs-Zirkonium-Korund-Steine für Brennöfen

Rezensionen

Es liegen noch keine Bewertungen vor.