Beschreibung

1.Schamottziegel Beschreibung

Schamottesteine sind feuerfeste Steine, die aus verschiedenen Rohstoffen, darunter auch feuerfestem Ton, hergestellt werden, kalzinierter weicher Ton und weicher Ton. Der Aluminiumoxidgehalt beträgt im Allgemeinen 30% -48% Feuerfestes Aluminiumoxid. Es handelt sich um ein schwach saures feuerfestes Produkt, das der Erosion durch saure Schlacke und saure Gase widerstehen kann, hat eine gute thermische Leistung, und ist beständig gegen schnelles Abkühlen und hohe Temperaturen.

Andere feuerfeste Steine

- Ziegel mit hohem Aluminiumoxidgehalt

- Mullitziegel

- Magnesia Ziegel

- Magnesia Alumina Spinellziegel

- Magnesia -Chromziegel

- Magnesia-Kohlenstoffstein

- Corundum Ziegel

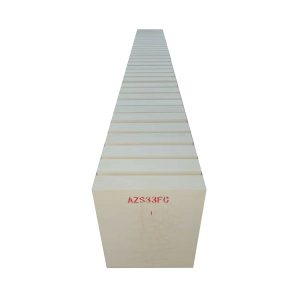

- AZS Ziegel

- Kieselstein

- Feuerfeste Siliziumkarbidsteine

- Feuerfeste Ankerstein

- Feuerfestes Silizium -Mullite -Ziegelstein

- Feuerfeste säurebeständige Steine

2.Schamottziegel-Funktion

(1) Hohe Feuerfestigkeit

(2) Hochtemperaturbeständig

(3) Gute Korrosionsbeständigkeit

(4) Gute Abplatzfestigkeit und Verschleißfestigkeit

(5) Gute Temperaturwechselbeständigkeit

(6) Hohe mechanische Festigkeit

(7) Gute Volumenstabilität bei hohen Temperaturen.

3.Technischer Parameter

| SK-Serie | SK30 | SK32 | SK34 | SK35 |

| AL2O3 | 30%-35% | 35%-38% | 38%-42% | 42%-50% |

| Fe2o3 /% | ≤ 3 | ≤ 3 | ≤ 3 | ≤ 2.5 |

| Feuerfestigkeit | ≥ 1690 ℃ | ≥ 1730℃ | ≥ 1750℃ | ≥ 1750℃ |

| B.D/G/CM3 | 1.9-2.0 | 2.0-2.1 | 2.1-2.18 | 2.15-2.3 |

| Stückgewicht(230*114*65mm) | ≥ 3,35 kg | ≥ 3,55 kg | ≥ 3,65 kg | ≥ 3,75 kg |

| A.P% | ≤ 26 | ≤ 24 | ≤ 24 | ≤ 22 |

| C.C.S | ≥ 20 MPa | ≥ 25 MPa | ≥ 30 MPa | ≥ 35 MPa |

| R.U.L | ≥ 1250 ℃ | ≥ 1300 ℃ | ≥ 1350 ℃ | ≥ 1420 ℃ |

| R.L.C% | 0~ -0.5(1350℃ ,2H) | 0~ -0.3(1350℃ ,2H) | 0~ -0.4(1450℃ ,2H) | +0.1~ -0.4(1450℃ ,2H) |

Aus Wikipedia: Feuerstein

Rezensionen

Es liegen noch keine Bewertungen vor.