Description

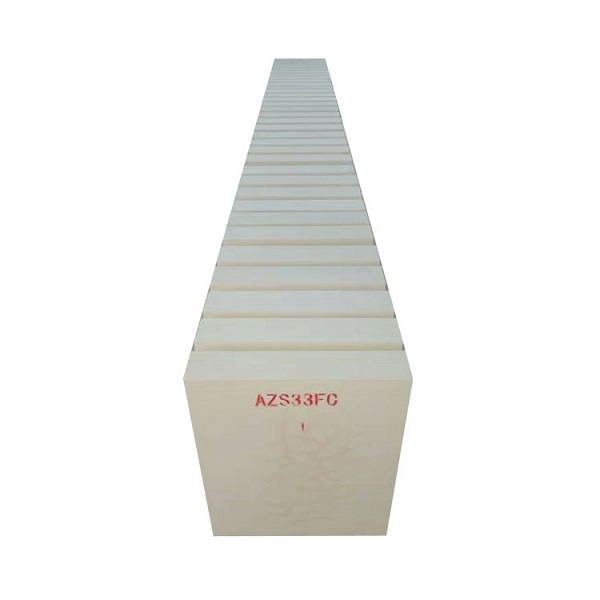

What is an AZS block?

Brique AZS (Alumina-Zirconia-Silica Brick) is a high-performance refractory material, mainly composed of alumina, zirconium oxide and silicon dioxide. Its main advantages include extremely high refractory resistance, erosion resistance and good thermal shock resistance, suitable for key parts of glass melting furnaces, such as pool walls, pool bottoms and melting parts. AZS bricks can effectively resist the erosion of glass liquid, extend the service life of the furnace body and reduce maintenance costs. Its wear resistance and mechanical strength also make it widely used in high-temperature industrial environments.

Autres briques réfractaires populaires

- Briques d'ancrage réfractaires

- Briques réfractaires en carbure de silicium

- Brique de silice

- Brique de carbone de magnésie

- Brique de magnésie chromée

Paramètre technique

| Article | AZS-33 | AZS-36 | AZS-41 |

| ZrO2 % | 32~36 | 35~40 | 40~44 |

| Al2O3 % | remain | remain | ≥50-60 |

| SiO2 % | ≤15.3 | ≤13 | ≤12.5 |

| Fe2O3 +TiO2+CaO+Na2O | ≤2,5 | ≤2,5 | ≤2,5 |

| Bubbling tendency(1300℃ 36hr,ordinary glass)% | ≤2,0 | ≤1.4 | ≤1,0 |

| Bulk density g/cm3 | ≤3.45 | ≤3.5 | ≤3.55 |

De Wikipédia:Réfractaire

What are the ingredients of AZS bricks?

The main ingredients of AZS refractory bricks are Al2O3 (alumine), ZrO2 (zirconium oxide) and SiO2 (dioxyde de silicium).

AZS refractory bricks are also called fused refractory bricks, and are also called fused zirconium corundum bricks. The English abbreviation AZS mainly represents the initials of the main elements Al2O3, ZrO2, and SiO2. The order of arrangement is based on the content of the elements, among which the content of alumina is about 48%, the content of chromium oxide is about 30%, and the content of silicon dioxide is generally about 20%.

Glass kiln azs brick

Differences between dolomite bricks and AZS bricks

- Composition: Dolomite bricks are mainly composed of calcium carbonate and magnesium carbonate, while AZS bricks are composed of alumina, zirconium oxide and silica.

- Domaines d'application: Dolomite bricks are more used in the steel and cement industries, while AZS bricks are mainly used in the glass industry.

- Performance: AZS bricks are generally superior to dolomite bricks in terms of fire resistance, erosion resistance and thermal shock resistance, but dolomite bricks are less expensive and suitable for certain specific high temperature environments.

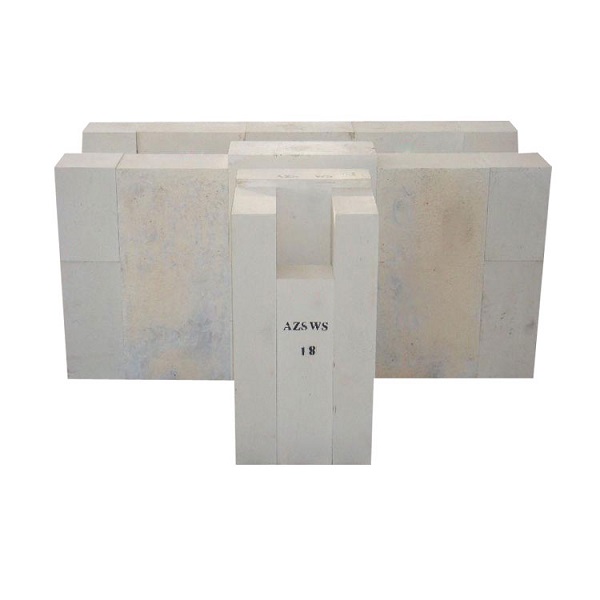

What are AZS bricks used for?

- Glass melting furnace: AZS bricks are mainly used in key parts of glass melting furnaces, such as pool walls, pool bottoms and melting parts. Its high fire resistance and erosion resistance can effectively resist the erosion of glass liquid and extend the service life of the furnace body.

- Résistance aux chocs thermiques: AZS bricks have good thermal shock resistance and can withstand frequent temperature changes during the operation of glass melting furnaces, reducing structural damage caused by thermal shock.

- Résistance à l'usure: Due to its high mechanical strength and wear resistance, AZS bricks reduce the maintenance and replacement frequency caused by mechanical wear during the glass manufacturing process, reducing production costs.

azs zirconium corundum bricks for kiln

Avis

Il n'y a pas encore d'avis.