Description

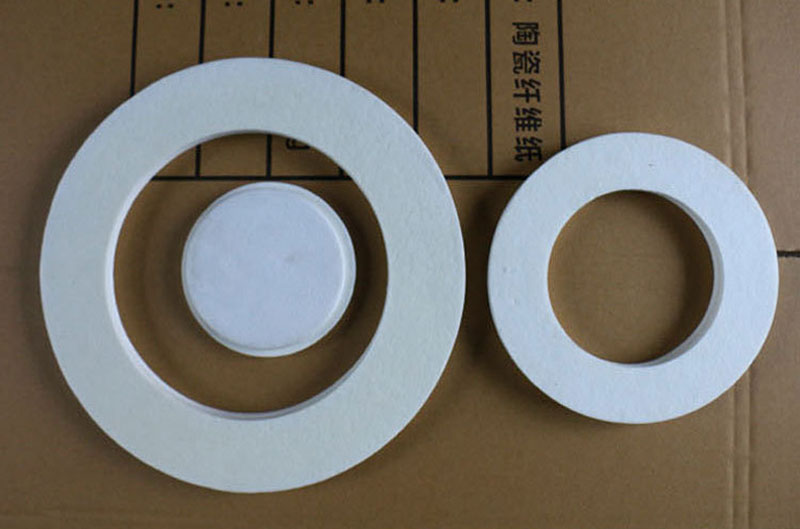

Overview of Ceramic Fiber Gasket

Ceramic fiber gaskets are made of alumina and silica, and have high temperature resistance, low thermal conductivity and thermal shock resistance, and are suitable for high temperature sealing and insulation.

It is light and soft, can be cut and installed, and is widely used in metallurgy, pétrochimique, power and other industries. It is an ideal material for high efficiency and energy saving.

joint en fibre de céramique blanc

Physical properties of ceramic fiber gaskets

- High temperature resistance: long-term use temperature can reach 1000–1400°C, short-term temperature resistance is higher.

- Faible conductivité thermique: excellent thermal insulation performance, reducing heat transfer.

- Lightweight: low density, usually between 200–400 kg/m³.

- Soft and compressible: adapt to irregular surfaces and provide good sealing.

- Résistance aux chocs thermiques: not easy to crack under rapid temperature changes.

- Stabilité chimique: acid and alkali corrosion resistance, oxidation resistance.

- Low heat capacity: fast heating and cooling, energy saving and high efficiency.

Production process

- Raw material melting: Alumina (Al₂O₃), silica (SiO₂) and other raw materials are melted at high temperature to form a uniform melt.

- Fiberization: The melt is drawn into fibers through blowing or spinning to form ceramic fiber cotton.

- Molding: The fiber cotton is made into a gasket of the required shape and thickness through needle punching, layering or molding.

- Heat treatment: High temperature curing to improve the stability and strength of the fiber.

- Cutting: Cut into specific sizes according to needs to adapt to different application scenarios.

ceramic fiber gasket nearby

ceramic fiber gasket temperature

1. Long-term use temperature

- Standard type: 1000–1260°C.

- Zirconium-containing type: 1260–1430°C.

2. Short-term temperature tolerance

- Can withstand short-term high temperatures 100–200°C higher than the long-term use temperature, suitable for sudden high temperature environments.

3. Low temperature performance

- Stable performance can be maintained in low temperature environments (such as -50°C), suitable for wide temperature range applications.

4. Stabilité aux chocs thermiques

- Not easy to crack when the temperature is rapidly increased or decreased, and excellent thermal shock resistance.

they are suitable for a wide temperature range of -50°C to 1430°C, and are ideal materials for high-temperature insulation and sealing.

The difference between ceramic fiber gasket, asbestos and glass fiber

1. High temperature resistance

- Ceramic fiber gasket: temperature resistance up to 1000–1400°C, can withstand higher temperatures in the short term.

- Asbestos: temperature resistance of about 500°C, easy to decompose at high temperatures.

- Glass fiber: temperature resistance of about 600°C, easy to soften after overheating.

2. Performances d'isolation thermique

- Ceramic fiber gasket: low thermal conductivity, significant thermal insulation effect.

- Asbestos: good thermal insulation performance, but performance decreases at high temperatures.

- Glass fiber: average thermal insulation performance, suitable for medium and low temperature environments.

3. Safety and environmental protection

- Ceramic fiber gasket: environmentally friendly material, but fiber dust needs to be protected.

- Asbestos: carcinogen, has been gradually eliminated.

- Glass fiber: environmentally friendly, but the fiber irritates the skin and respiratory tract.

4. Mechanical properties

- Ceramic fiber gasket: soft and compressible, but low mechanical strength.

- Asbestos: high mechanical strength, but easy to become brittle.

- Glass fiber: good strength, but easy to deform at high temperature.

5. Cost

- Joints en fibre de céramique: higher cost, but long life.

- Asbestos: low cost, but health risks.

- Fiberglass: moderate cost, but limited high temperature performance.

They have obvious advantages in high temperature resistance, heat insulation and environmental protection, and are an ideal choice to replace traditional materials, but their mechanical properties and costs need to be weighed according to specific needs.

price ceramic fiber gasket

Application of Ceramic Fiber Gasket

- Metallurgical industry: high temperature furnace lining, molten metal pipeline sealing.

- Petrochemical and power: thermal insulation and sealing of boilers, reactors, valves, flanges.

- Glass and ceramic industry: kiln door gaps, thermal equipment sealing.

- Aerospace: engine insulation components.

- Automobile manufacturing: exhaust system insulation gaskets.

- Other high temperature equipment: hot air ducts, heating element insulation.

Avis

Il n'y a pas encore d'avis.