Description

Signification brique de corindon chromé

La brique de corindon chromé est un matériau réfractaire composé d'alumine et de chrome comme matières premières principales, par fusion à haute température, fonderie, frittage et autres processus.

Sa principale composition minérale est une solution solide α-Al2O3-Cr2O3, la composition minérale secondaire est une petite quantité de spinelle composite (ou pas de spinelle composite), et la teneur en oxyde de chrome est 1% à 30%.

Ce matériau présente non seulement une excellente résistance aux températures élevées, mais a également les caractéristiques de résistance à l'usure, résistance aux chocs thermiques et résistance à la corrosion acide et alcaline.

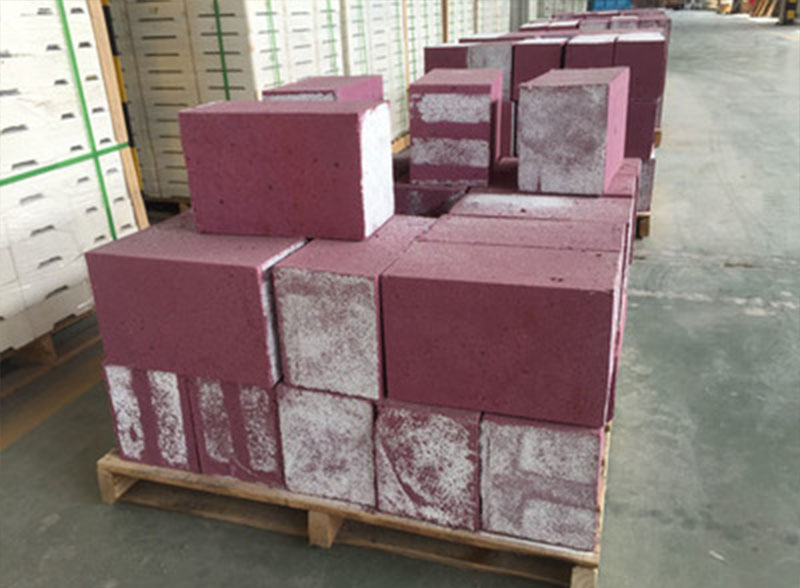

acheter des briques de corindon chromé

Propriétés physiques de la brique de corindon chromé

| Propriétés physiques | décrire |

|---|---|

| Résistance | Plus de 1750 ℃ |

| Température de ramollissement sous charge | Plus de 1750 ℃ |

| Résistance à la compression à température normale | Les briques de corindon chromé haute performance sont généralement de 150 MPa, les briques de corindon de haute pureté sont généralement de 70 à 100 MPa |

| Stabilité aux chocs thermiques | À mesure que la teneur en Cr2O3 augmente, ça diminue. La résistance aux chocs thermiques des briques de corindon chromé à faible teneur en Cr2O3 est meilleure. |

| Résistance à l'érosion des scories | Plus résistant que les autres matériaux oxydés, notamment dans les matériaux réfractaires contenant du Cr2O3 |

De Wikipédia: Brique réfractaire

Processus de production de briques de corindon chromé

Les produits en briques de corindon chromé sont constitués de corindon et d'oxyde de chrome fondu comme principales matières premières, avec des additifs tels que de la micropoudre, après avoir mélangé, moulage, séchage, et cuisson à haute température dans un four navette. Ce procédé garantit la résistance à l'usure, résistance aux chocs thermiques et résistance à la corrosion acide et alcaline du produit.

Caractéristiques de performance des briques de corindon chromé

- Résistance aux hautes températures: capable de résister à l'environnement de travail du revêtement de four à haute température.

- Résistance à l'usure: conservent toujours de bonnes propriétés mécaniques à haute température.

- Résistance à la corrosion: en particulier la tolérance aux environnements acides et alcalins.

- Stabilité aux chocs thermiques: bonne résistance aux chocs thermiques, adapté à une utilisation dans des conditions de choc thermique.

brique de corindon chromé à vendre

corindon de chrome vs oxyde d'aluminium

| fonctionnalité | Corindon chromé | Alumine |

|---|---|---|

| Définition | Alumine contenant des ions chrome (Cr³⁺), rouge ou rose, souvent utilisé comme matériau de pierre précieuse | Communément appelée alumine, il existe deux variantes principales, un et c, qui sont les matières premières de base pour la préparation de l'aluminium métallique |

| Principaux ingrédients | α-alumine | Al₂O₃ |

| Couleur | Rouge vif ou rose | En fonction des impuretés, généralement gris |

| Structure | Structure d'emballage hexagonale la plus proche | type α: emballage fermé hexagonal; type γ: emballage serré cubique à faces centrées |

| Applications | Fabrication de pierres précieuses, matériaux réfractaires haut de gamme | Fabriquer de l'aluminium métallique, matériaux réfractaires, matériaux abrasifs, substrats de cartes de circuits intégrés |

Domaines d'application de la brique de corindon chromé

- Industrie chimique du charbon: utilisé dans les éléments clés des fours de l'industrie chimique.

- Four à fibre de verre: surtout dans un four en fibre de verre sans alcali.

- Incinérateur de déchets: comme un élément important, améliorer l'efficacité de la combustion.

- Four à noir de carbone: matériau de doublure, améliorer la résistance à l'usure et à la corrosion du corps du four.

- Four de fusion du cuivre: matériau de doublure, prolonger la durée de vie du corps du four.

- Four de chauffage à laminage d'acier: utilisé dans les glissières et les plates-formes en acier pour améliorer la sécurité de la production.

Avis

Il n'y a pas encore d'avis.