Description

Description de la brique de corindon

La brique de corindon est un matériau réfractaire avec de l'alumine (Al2O3) comme composant principal, avec un contenu de plus de 90%. En raison de son point de fusion élevé, haute dureté et haute résistance, il est largement utilisé dans les revêtements de fours à haute température et les meubles de four.

Fonctionnalité

(1) Résistance aux hautes températures

(2)Haute résistance,haute résistance à la compression

(3)Excellente résistance aux chocs thermiques

(4) Densité apparente élevée, bonne conductivité thermique

(5) Bonne résistance à l'usure et aux acides

(6) résistance à la corrosion alcaline

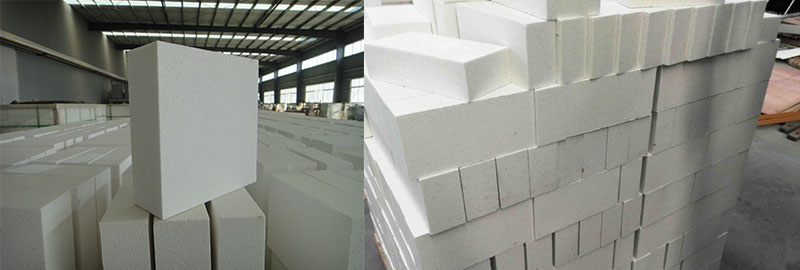

Brique de corindon

Taille régulière

- 230*114*65

- 250*123*65

- 171*113*65

- 230*65/55*114

- 230*114*65/55

- 230*114*65/45

- 230*114*20

- 230*57*65

- 230*150*75

- 230*150/120*75

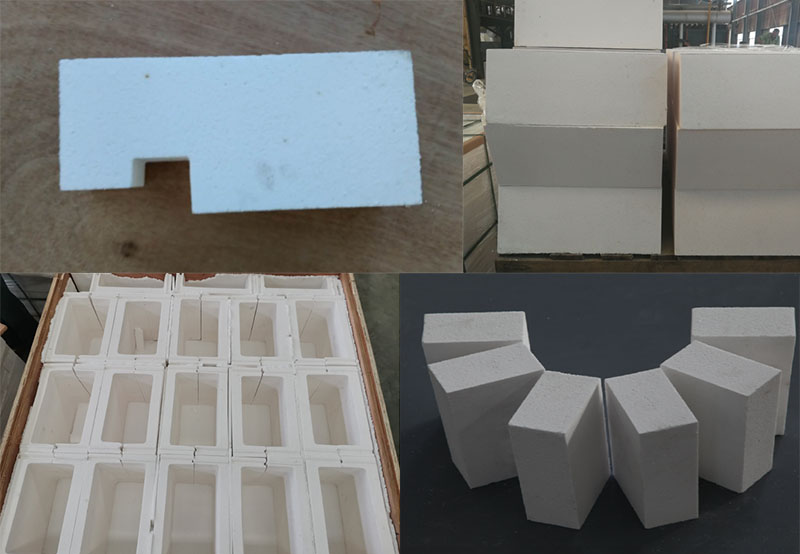

Personnalisable à n'importe quelle forme

Personnalisation de la forme

Paramètre technique

| Article | Brique de corindon 99 | Brique de corindon 90 | brique de mullite de corindon |

| Al2O3 % | ≥99 | ≥90 | ≥80 |

| SiO2 % | ≤0,2 | ≤8 | ≤18 |

| Fe2O3 % | ≤0,2 | ≤0,2 | ≤0,3 |

| Densité apparente g/cm3 | ≥3,2 | ≥3 | ≥2,8 |

| Porosité apparente % | ≤19 | ≤18 | ≤18 |

| Compressif froid résistance MPa | ≥100 | ≥100 | ≥100 |

| (0.2Mpa,0.6%)Charger le ramollissement a commencé à température °C | ≥1700 | ≥1700 | ≥1700 |

De Wikipédia:Réfractaire

Processus de production

Méthode de frittage: Utilisez de l'alumine frittée et de l'acide phosphorique ou d'autres liants pour fabriquer des briques de corindon non brûlées.

Méthode d'électrofusion: Les matières premières d'alumine de haute pureté sont fondues et coulées à une température élevée de plus de 2000°C.

Ligne de production de briques de corindon Henan LiTe

Échelle de production: 5 40 fours navettes cubiques, 5 presses, système de dosage automatique, production quotidienne de 80 tonnes, production annuelle de 20,000 tonnes

Processus de production: matières premières – écrasement (0-1mm, 1-3mm, 3-5mm) – mélange – moulage – séchage (200℃) – frittage (1600℃-1700℃) – conditionnement

Ligne de production

Domaines d'application des briques de corindon

1. Dans l'industrie sidérurgique;

2. Dans l'industrie de la fusion des métaux non ferreux, la résistance à l'usure et à la corrosion des briques en corindon est nettement meilleure que celle des autres briques;

3. Dans l'industrie du noir de carbone, sur le réacteur à noir de carbone

4. Dans l'industrie pétrochimique, dans le four de gazéification des usines d'engrais de grande et moyenne taille

Avis

Il n'y a pas encore d'avis.