Description

Description des briques réfractaires en carbure de silicium

Les briques réfractaires en carbure de silicium sont un matériau réfractaire haute performance, composé principalement de carbure de silicium (SiC), avec une excellente résistance aux hautes températures, résistance aux chocs thermiques et stabilité chimique. Ils sont largement utilisés dans les environnements à haute température tels que les fours industriels à haute température, fours de fusion d'aluminium, fours à verre, etc.. Son caractère réfractaire peut atteindre plus de 1800°C, et il a une forte résistance à l'oxydation et à l'érosion des scories, particulièrement adapté aux environnements acides.

Les briques réfractaires en carbure de silicium ont une excellente conductivité thermique et une excellente stabilité thermique, ce qui contribue à améliorer la durée de vie et l'efficacité de travail du corps du four. Grâce à la sélection de matières premières en carbure de silicium de haute pureté et à des processus de production avancés, nos briques en carbure de silicium répondent non seulement à des exigences industrielles strictes, mais également fournir des solutions personnalisées pour répondre aux besoins des différents clients.

Types spéciaux:

- Carbure de silicium lié au nitrure Briques: Utiliser du nitrure de silicium (Si₃N₄) comme liant pour améliorer encore la résistance aux chocs thermiques et à l'érosion.

- Briques de carbure de silicium liées par réaction: En introduisant du silicium (Et) pendant le processus de cuisson pour former du carbure de silicium supplémentaire, la solidité et la résistance à l'érosion du corps de brique sont améliorées.

Paramètre technique de briques réfractaires en carbure de silicium

| Article | Brique de carbure de silicium à liaison oxyde | brique de carbure de silicium liée au nitrure de silicium | Brique en carbure de silicium recristallisé | |||

| Compositions chimiques % | SiC | 85 | SiC | 70-80 | SiC | 100 |

| SiO2 | 10 | Si3N4 | 15-25 | |||

| Caractère réfractaire °C | 1800 | – | – | |||

| Porosité apparente % | 13-16 | 10-18 | 0.5-32 | |||

| Densité apparente g/cm3 | 2.55-2.62 | 2.5-2.8 | 2.1-3.3 | |||

| Résistance à la compression à froid MPa | 100-120 | 100 | 68.6-3700 | |||

| Caractère réfractaire sous charge °C | 1800 | 1600 | 1700 | |||

| Résistance aux temps de chocs thermiques | 30 | – | 50-150 | |||

| Température de service °C | – | – | 1800 | |||

De Wikipédia:Réfractaire

Que faire s'il y a des bulles après la cuisson des briques réfractaires en carbure de silicium

1. Analyse des causes: problèmes de matières premières; mélange inégal; température et durée de cuisson; problèmes de moisissure

2. Méthodes de traitement: réduire les substances volatiles et améliorer la pureté des matières premières; mélange uniforme et contrôle de l'humidité; contrôler raisonnablement la température, prolonger le temps de tir, et chauffer par étapes; contrôler l’humidité des moules et utiliser des moules de haute qualité; utiliser des antimousses et des agents de nivellement pour réduire les bulles

Référence de cas

La pulvérisation de poudre d'aluminium sur des plaques de carbure de silicium produit des bulles: la poudre d'aluminium réagit avec l'eau dans un environnement alcalin pour générer de l'hydrogène et des bulles. La formation de bulles peut être réduite en ajustant la quantité de poudre d'aluminium et les conditions de réaction.

![]()

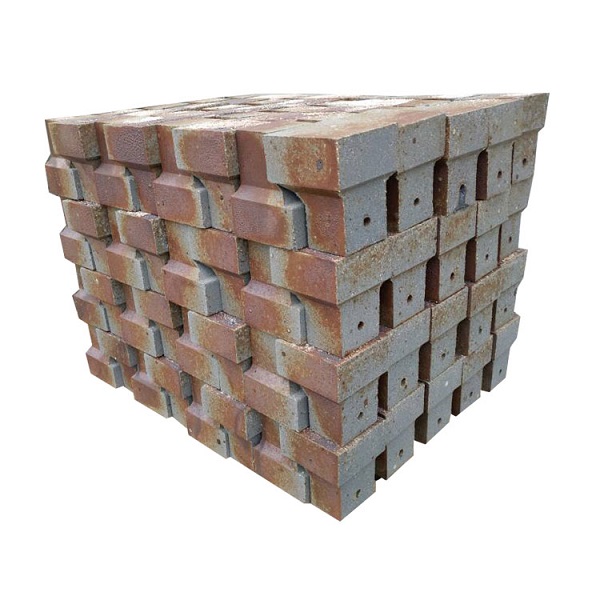

Briques réfractaires en carbure de silicium

Processus de production de brique sic:

- Sélection des matières premières: Sélectionnez une poudre et un liant de carbure de silicium de haute pureté (comme le silicate, argile, etc.).

- Lot: Mélanger le carbure de silicium et le liant en proportion.

- Moulage: Utilisez une presse à briques ou un autre équipement de moulage pour transformer le mélange en briques.

- Cuisson: Frittage à haute température (généralement 1400°C – 1700°C) assure la performance des briques réfractaires en carbure de silicium.

- Refroidissement: Refroidir lentement pour éviter les fissures.

- Inspection et emballage: Emballage après contrôle qualité.

Domaines d'application de la brique de carborundum:

- Le revêtement des fours industriels à haute température, fours de fusion d'aluminium, et fours à verre.

- Équipements à haute température tels que fours à céramique et réacteurs chimiques.

- Quelques utilisations particulières dans la sidérurgie, comme la buse du four d'affinage sous vide RH.

Nos prestations

Conditionnement

- Emballage en carton + palette

- Palette + film plastique + ruban de fixation

- Emballage selon les exigences du client.

FAQ

T1: Quelle est la quantité minimum de commande pour une commande?

UN: Il n'y a pas de limite, nous pouvons vous fournir les meilleures suggestions et solutions en fonction de votre situation.

T2: Quelles conditions de paiement pouvez-vous accepter?

UN: Nous pouvons utiliser T/T, L/C, Western union, MoneyGram, Paypal.

T3: Votre entreprise accepte-t-elle la personnalisation?

UN: Nous avons notre propre usine et une excellente équipe technique, nous acceptons le service OEM.

T4: Qu’en est-il de la certification de votre entreprise?

UN: Nous pouvons fournir ISO9001 et des rapports de test, et nous pouvons également demander d'autres certifications nécessaires.

Avis

Il n'y a pas encore d'avis.