Keterangan

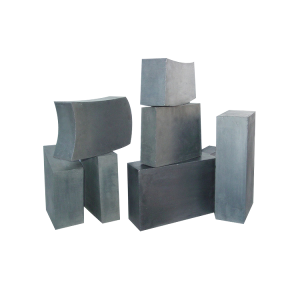

Apa itu batu bata silika?

Bata silika terbuat dari bahan batu kuarsa, Konten SiO2 lebih dari 93%, ia memiliki ketahanan korosi terak asam dan kekuatan suhu tinggi yang tinggi. Suhu awal pelunakan beban adalah 1620~1670°C. batu bata tahan api silika tidak akan berubah bentuk setelah penggunaan jangka panjang pada suhu tinggi, dan memiliki stabilitas kejutan termal yang rendah. Ekspansi sisa ini akan mengencangkan sambungan dan memastikan bahwa pasangan bata memiliki kedap udara dan kekuatan struktural yang baik.

Batu bata tahan api yang mengandung silikon lainnya

Batu bata silika

parameter teknis batu bata silika alumina

| Barang | GZ-96 | GZ-95 | GZ-94 | GZ-93 |

| SiO2 % | 96 | 96 | 94 | 93 |

| Fe2O3 % | 1.0 | 1.2 | 1.4 | 1.6 |

| sifat tahan api °C | 1710 | 1710 | 1710 | 1690 |

| Porositas yang tampak % | 22 | 22 | 23 | 25 |

| Kekuatan menghancurkan dingin Mpa | 29.4 | 29.4 | 24.5 | 19.6 |

| Sifat tahan api di bawah beban(0.2MPa) °C≥ | 1660 | 1650 | 1640 | 1620 |

| massa jenis sebenarnya g/cm³ | 2.34 | 2.37 | 2.38 | 2.39 |

Dari Wikipedia:Tahan panas

sifat bata tahan api silika

- Tahan panas: Sifat tahan api batu bata silika umumnya antara 1690-1730℃.

- Suhu pelunakan beban: Suhu pelunakan beban batu bata tahan api alumina silika relatif tinggi, umumnya antara 1640-1680℃, mendekati titik leleh tridimit (1670℃) dan titik leleh kristobalit (1713℃).

- Stabilitas volume: Volume batu bata tahan api silika stabil pada kisaran di atas 300℃ hingga mendekati titik leleh (tridimit atau kristobalit). Saat dipanaskan hingga 1450℃, itu akan menghasilkan ekspansi volume sekitar 1.5%-2.2%, yang bermanfaat bagi kekuatan struktural dan kedap udara pada pasangan bata.

- Ketahanan terhadap guncangan termal: Ketahanan guncangan termal dari batu bata tahan api alumina silika buruk, dan jumlah siklus pendinginan air secara umum 1-4 kali.

- Kepadatan sebenarnya: Kepadatan sebenarnya dari batu bata api alumina silika adalah salah satu indikator penting untuk menilai tingkat transformasi kristalnya. Umumnya diperlukan di bawah 2,38g/cm³, dan batu bata silika harus di bawah 2,35g/cm³.

Batu bata silika untuk tempat pembakaran semen

Hubungan antara sifat tahan api batu bata api alumina silika dan tridimit

Dalam batu bata tahan api silika yang dibakar dengan baik, kandungan tridimit dapat mencapai 50%-80%. Titik leleh tridimit adalah sekitar 1670℃, sedangkan suhu deformasi beban batu bata silika leburan berfluktuasi antara 1640-1680℃, yang mendekati titik leleh tridimit. Karena itu, kehadiran tridimit meningkatkan refraktori dan suhu deformasi beban batu bata silika, memungkinkan mereka untuk menjaga stabilitas struktural di lingkungan bersuhu tinggi.

Mengapa silika digunakan untuk membuat batu bata untuk tungku suhu tinggi?

Karena sifat fisik dan kimianya, ini sangat tahan api dan dapat tetap stabil di lingkungan bersuhu tinggi, yang berarti tidak akan mudah pecah atau berubah bentuk saat suhu berubah. Ini memiliki ketahanan korosi yang baik terhadap zat asam, yang memungkinkan mereka untuk mempertahankan integritas strukturalnya bahkan dalam lingkungan asam. Konduktivitas termalnya yang rendah membantu menahan panas di lingkungan bersuhu tinggi, sehingga meningkatkan efisiensi energi.

Bengkel produksi batu bata silika alumina tinggi

Apa fungsi silika pada batu bata?

Di industri kaca: bata api silika alumina leburan ringan digunakan untuk insulasi panas kubah kiln kaca, mengurangi kehilangan panas dan meningkatkan efisiensi proses peleburan. Di industri baja: batu bata silika ringan digunakan untuk dinding dan kubah tanur panas ringan. Di industri lain: batu bata tahan api silika juga banyak digunakan dalam bidang industri suhu tinggi seperti metalurgi dan keramik.

Catatan

Karena bentuk kristal sisa kuarsa berubah pada suhu rendah, volume produk mengandung silika sangat berubah. Karena itu, saat memanggang tungku, suhu tidak boleh dinaikkan terlalu cepat di bawah 600℃, dan harus didinginkan perlahan hingga 600℃ untuk menghindari retak.

Hindari kontak dengan terak alkali sebisa mungkin.

Sedang mengemas

(1)Kemasan karton

(2)baki + film plastik + pita tetap

(3) palet: 1*1M,0.93*0.93M .

(4)berat baki: 1.6~2,0ton.

![]()

pengemasan dan pengiriman batu bata silika menyatu

Ulasan

Belum ada ulasan.