Описание

Refractory Silicon Carbide bricks Description

Refractory Silicon Carbide Bricks are a high-performance refractory material, mainly composed of silicon carbide (Карбид кремния), with excellent high temperature resistance, thermal shock resistance and chemical stability. They are widely used in high temperature environments such as high temperature industrial furnaces, печи для плавки алюминия, стекольные печи, и т. д.. Its refractoriness can reach more than 1800°C, and it has strong resistance to oxidation and slag erosion, especially suitable for acidic environments.

Refractory Silicon carbide bricks have excellent thermal conductivity and thermal stability, which helps to improve the service life and working efficiency of the furnace body. Through the selection of high-purity silicon carbide raw materials and advanced production processes, our silicon carbide bricks not only meet strict industrial requirements, but also provide customized solutions to meet the needs of different customers.

Special types:

- Карбид кремния, связанный нитридом Bricks: Use silicon nitride (Si₃N₄) as a binder to further improve thermal shock resistance and erosion resistance.

- Reaction Bonded Silicon Carbide Bricks: By introducing silicon (И) during the firing process to form additional silicon carbide, the strength and erosion resistance of the brick body are enhanced.

Refractory Silicon Carbide Bricks Technical parameter

| Элемент | Oxide bond silicon carbide brick | silicon nitride bonded silicon carbide brick | Recrystallized silicon carbide brick | |||

| Chemical Compositions % | Карбид кремния | 85 | Карбид кремния | 70-80 | Карбид кремния | 100 |

| SiO2 | 10 | Си3Н4 | 15-25 | |||

| Refractoriness °C | 1800 | – | – | |||

| Видимая пористость % | 13-16 | 10-18 | 0.5-32 | |||

| Основная плотность g/cm3 | 2.55-2.62 | 2.5-2.8 | 2.1-3.3 | |||

| Cold compressive strength MPa | 100-120 | 100 | 68.6-3700 | |||

| Refractoriness under load °C | 1800 | 1600 | 1700 | |||

| Resistance to thermal shock times | 30 | – | 50-150 | |||

| Service temperature °C | – | – | 1800 | |||

Из Википедии:Рефрактерный

What to do if there are bubbles after silicon carbide refractory bricks are fired

1. Cause analysis: raw material problems; uneven mixing; firing temperature and time; mold problems

2. Treatment methods: reduce volatile substances and improve raw material purity; uniform mixing and control humidity; reasonably control temperature, extend firing time, and heat up in stages; control mold humidity and use high-quality molds; use defoamers and leveling agents to reduce bubbles

Case reference

Spraying aluminum powder on silicon carbide plates produces bubbles: aluminum powder reacts with water in an alkaline environment to generate hydrogen and bubbles. The formation of bubbles can be reduced by adjusting the amount of aluminum powder and reaction conditions.

![]()

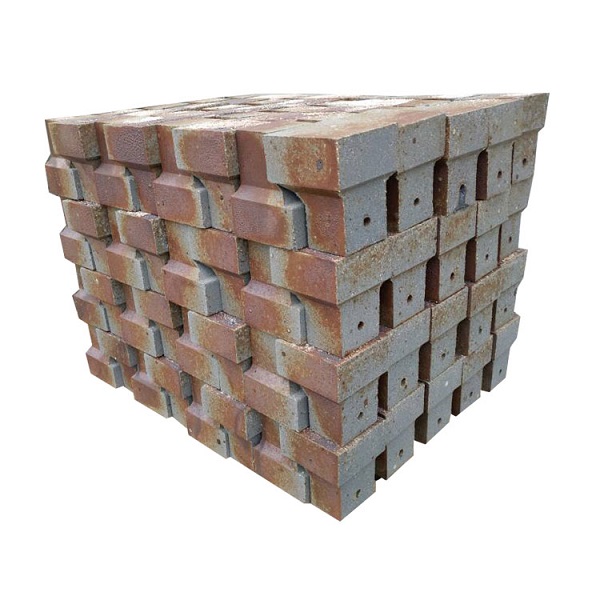

Огнеупорный карбидокремниевый кирпич

Production process of sic brick:

- Выбор сырья: Select high-purity silicon carbide powder and binder (such as silicate, глина, и т. д.).

- Batch: Mix silicon carbide and binder in proportion.

- Формование: Use brick press or other molding equipment to make the mixture into bricks.

- Стрельба: Sintering at high temperature (usually 1400°C – 1700°С) ensures the performance of Refractory silicon carbide bricks.

- Охлаждение: Cool slowly to prevent cracks.

- Inspection and packaging: Packing after quality inspection.

Application areas of carborundum brick:

- The lining of high-temperature industrial furnaces, печи для плавки алюминия, and glass kilns.

- High-temperature equipment such as ceramic firing kilns and chemical reactors.

- Some special uses in the steel industry, such as the nozzle of the RH vacuum refining furnace.

Our Services

Упаковка

- Carton packaging + pallet

- Pallet + пластиковая пленка + fixing tape

- Packaging according to customer requirements.

Часто задаваемые вопросы

Q1: What is the minimum order quantity for an order?

А: There is no limit, we can provide the best suggestions and solutions according to your situation.

Q2: What payment terms can you accept?

А: We can use T/T, L/C, Western Union, MoneyGram, Paypal.

Q3: Does your company accept customization?

А: We have our own factory and excellent technical team, we accept OEM service.

Q4: How about your company’s certification?

А: We can provide ISO9001 and test reports, and we can also apply for other necessary certifications.

Отзывы

Пока нет отзывов.