คำอธิบาย

คำจำกัดความของวัสดุทนไฟ Ramming

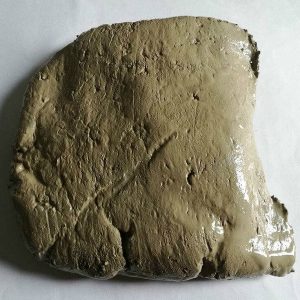

วัสดุทนไฟกระแทก หมายถึงวัสดุทนไฟอสัณฐานที่สร้างขึ้นโดยการกระแทก (คู่มือหรือเครื่องกล) และแข็งตัวภายใต้ความร้อนสูงกว่าอุณหภูมิปกติ. ทำโดยการผสมมวลรวมทนไฟ, ผง, สารยึดเกาะ, สารผสมที่มีเกรดหนึ่ง, และเติมน้ำหรือของเหลวอื่นๆ.

มวลการกระแทกของวัสดุทนไฟเป็นวัสดุเทกองที่ประกอบด้วยวัสดุที่เป็นเม็ดในสัดส่วนที่สูงและมีสารยึดเกาะและส่วนประกอบอื่นๆ ในสัดส่วนที่ต่ำ, หรือแม้แต่วัสดุที่เป็นเม็ดและเป็นผงทั้งหมด, ซึ่งจะต้องสร้างโดยการกระแทกอย่างแรง.

ผลิตภัณฑ์อสัณฐานอื่นๆ

วัสดุทนไฟกระแทก

ลักษณะของวัสดุทนไฟ

ลักษณะทางกายภาพ

- ทนต่ออุณหภูมิสูง: วัสดุทนไฟสามารถทนต่ออุณหภูมิที่สูงกว่าวัสดุก่อสร้างทั่วไปได้มาก, และความทนไฟของพวกเขามักจะเกิน 1,580 ℃.

- ความต้านทานการเสียรูป: ภายใต้สภาวะที่มีอุณหภูมิสูง, วัสดุทนไฟสามารถรักษารูปร่างและความเสถียรของมิติได้ และไม่เสี่ยงต่อการอ่อนตัวหรือเสียรูป.

- ความต้านทานการกัดกร่อน: วัสดุทนไฟมีความสามารถในการต้านทานการกัดกร่อนของสารเคมี และสามารถรักษาความสมบูรณ์ของโครงสร้างเมื่อสัมผัสกับสารที่มีฤทธิ์กัดกร่อน.

ลักษณะทางเคมี

- จุดหลอมเหลวสูง: วัสดุทนไฟมักจะมีจุดหลอมเหลวสูง, ซึ่งหมายความว่าสามารถใช้งานได้นานที่อุณหภูมิใกล้กับจุดหลอมเหลวโดยไม่ละลาย.

- ความเสถียรทางเคมี: วัสดุทนไฟยังคงสามารถรักษาคุณสมบัติทางเคมีให้คงที่ที่อุณหภูมิสูงและไม่ง่ายที่จะทำปฏิกิริยากับสารอื่น.

ลักษณะกระบวนการ

- ความสามารถในการแปรรูป: วัสดุทนไฟสามารถทำได้ผ่านกระบวนการต่างๆ, เช่นการเผาผนึก, การคัดเลือกนักแสดง, ฯลฯ, เพื่อปรับให้เข้ากับความต้องการการใช้งานที่แตกต่างกัน.

- ทนต่อการสึกหรอ: วัสดุทนไฟมักจะมีความต้านทานการสึกหรอที่ดีและสามารถใช้งานได้นานในสภาพแวดล้อมที่มีแรงเสียดทานสูง.

ลักษณะการใช้งาน

- ประสิทธิภาพการต่อต้านอนุมูลอิสระ: วัสดุทนไฟบางชนิดมีประสิทธิภาพในการต่อต้านอนุมูลอิสระได้ดี, ซึ่งสามารถยืดอายุการใช้งานในสภาพแวดล้อมออกซิไดซ์ที่อุณหภูมิสูง.

- คุณสมบัติของฉนวนความร้อน: วัสดุทนไฟที่ใช้ในอุตสาหกรรมก่อสร้างก็มีคุณสมบัติเป็นฉนวนความร้อนที่ดีเช่นกัน, ซึ่งสามารถลดการถ่ายเทความร้อนได้อย่างมีประสิทธิภาพ.

ตัวอย่างวัสดุทนไฟกระแทก

1. มวลการกระแทกที่ทนไฟของอลูมินาสูง

2. มวลกระแทกที่ทนไฟของแมกนีเซียม

- มวลกระแทกที่ทนไฟของแมกนีเซียมสำหรับเตาเหนี่ยวนำแบบไร้แกน

- มวลกระแทกด้านล่างของเตาไฟฟ้า

3. มวลการกระแทกของซิลิกา

4. มวลกระแทกเซอร์โคเนียม

5. มวลกราไฟท์กระแทก.

6. มวลกระแทกแห้ง

- มวลแห้งคอรันดัม

- มวลแห้งของซิลิกา

- มวลแห้งของซิลิกา-อลูมินา

- แมกนีเซียมและแมกนีเซียมแคลเซียมแห้ง

การใช้วัสดุทนไฟกระแทก

- ใช้ในสถานประกอบการเหล็ก: ทัพพีเหล็ก; เตาไฟฟ้าด้านบน; เตาทำความร้อนคานเดิน

- ใช้ในอุตสาหกรรมปูนซีเมนต์: หม้อต้มพลังงานความร้อนเหลือทิ้ง

- ใช้ในเตาเผาอุตสาหกรรม: การซ่อมแซมและการก่อสร้างซับ; เติมมุมเตา; เป็นวัสดุซับใน

- ใช้ในเตาเผาซิลิเกต: การวางด้านล่างและการปะแบบร้อน

- ใช้ในเตาเหนี่ยวนำ, เตาถลุงอลูมิเนียม, ฯลฯ.: วัสดุบุเตา

- ใช้ในเตาไฟฟ้าและเตาเปิด: การก่อสร้างหรือซ่อมแซมสระหลอมและพวยเหล็ก; วัสดุบุผิวและวัสดุซ่อมแซมด้านล่างเตาไฟฟ้าและความลาดชันของเตาไฟฟ้า

- ใช้ในการเติม: เติมช่องว่างระหว่างอุปกรณ์ทำความเย็นของเตาเผากับชั้นปรับระดับของอิฐหรืออิฐ

รีวิว

ยังไม่มีบทวิจารณ์.