Tanım

Overview of Corundum Sagger

Corundum sagger, also referred to as an alumina crucible or corundum container, is a high-temperature ceramic vessel crafted primarily from alumina (Al₂O₃). Renowned for its exceptional thermal stability, chemical resistance, and durability, it is widely used in industries such as ceramics, metalurji, and chemical processing.

Designed to withstand extreme temperatures and harsh environments, corundum sagger ensures efficiency and reliability in demanding applications.

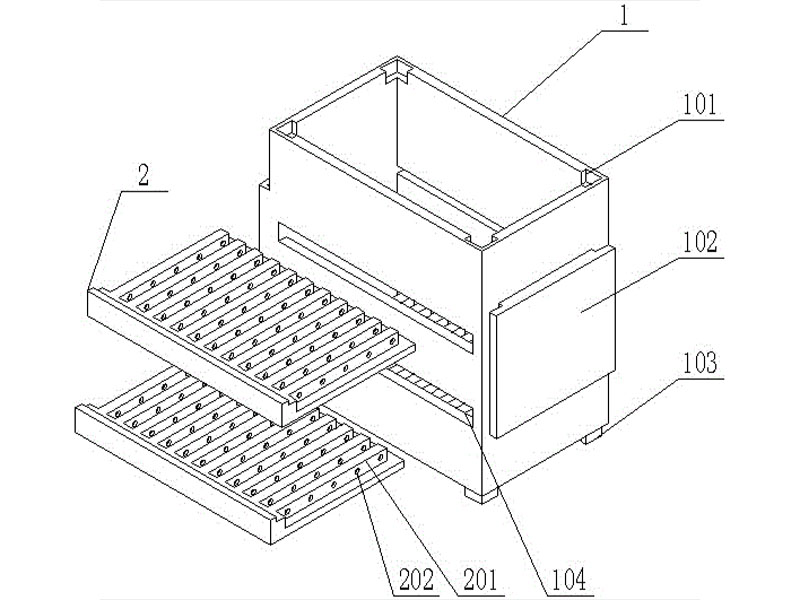

Corundum sagger design diagram

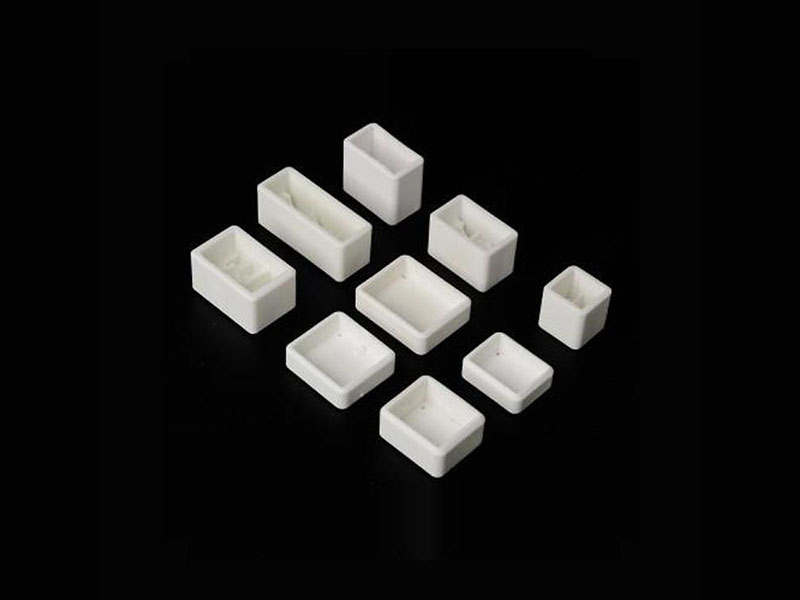

Hot-selling models and sizes of Corundum sagger

Standard Cylindrical Sagger Sizes: 50 ml, 100 ml, 500 ml, 1 liter, 5 liters, 10 liters

Use: General high-temperature applications like metal melting and ceramic firing.

Rectangular Sagger Sizes: 10 cm x 10 cm x 5 cm, 20 cm x 20 cm x 10 cm, 30 cm x 30 cm x 15 cm

Use: Firing ceramic tiles, plates, and other flat products.

Custom-Designed Sagger Sizes: Tailored dimensions (e.g., 15 cm diameter x 20 cm height, 25 cm x 25 cm x 12 cm)

Use: Specialized industrial or laboratory needs.

Large Industrial Sagger Sizes: 20 liters, 30 liters, 50 liters

Use: High-volume processes in metallurgy and chemical industries.

Small Laboratory Sagger Sizes: 50 ml, 100 ml, 250 ml

Use: Research and development, small-scale experiments.

Size of Corundum sagger

Production Process of Corundum Sagger

- Raw Material Selection: High-purity alumina powder is chosen as the primary material.

- Mixing and Grinding: The alumina powder is mixed with binders and additives to achieve the desired consistency.

- Kalıplama: The mixture is shaped into the desired crucible form using techniques like pressing or casting.

- Drying: The molded crucibles are dried to remove moisture and prevent cracking.

- Sintering: The dried crucibles are fired at high temperatures (1600°C – 1800°C) to achieve densification and strength.

- Quality Inspection: Each crucible is tested for density, termal şok direnci, and dimensional accuracy.

Comparison of Corundum Sagger with Other Saggers

- Silicon Carbide Sagger: While silicon carbide offers good thermal conductivity, corundum sagger excels in chemical resistance and durability at higher temperatures.

- Graphite Sagger: Graphite is lightweight and conductive but lacks the chemical inertness and high-temperature stability of corundum sagger.

- Clay-Graphite Sagger: These are cost-effective but have lower thermal shock resistance and shorter lifespans compared to corundum sagger.

- Quartz Sagger: Quartz is suitable for lower temperatures but cannot withstand the extreme heat that corundum sagger can handle.

Corundum sagger prices

Applications of Corundum Sagger

- Ceramics Industry: Ideal for firing ceramic products like tiles, porcelain, and sanitaryware.

- Metallurgy: Used for melting and refining metals such as gold, gümüş, and platinum.

- Chemical Processing: Suitable for handling corrosive chemicals and high-temperature reactions.

- Electronics: Essential for sintering electronic components and manufacturing semiconductors.

- Research and Development: Used in labs for high-temperature experiments and material testing.

Why Choose Corundum Sagger?

When it comes to high-temperature applications, corundum sagger stands out as a reliable and efficient solution. Its ability to withstand extreme heat, resist chemical corrosion, and maintain structural integrity makes it a top choice for industries that demand precision and durability.

Whether you’re in ceramics, metalurji, or chemical processing, investing in a high-quality alumina crucible ensures optimal performance and cost-effectiveness in the long run.

Yorumlar

Henüz yorum yok.