Tanım

Introduction to acid-resistant bricks

Refractory Acid-resistant bricks are a type of building material specially designed to resist acid corrosion and are widely used in chemical, pharmaceutical, metallurgical and other industrial fields. Made of high-alumina clay, silica and other materials, they have excellent acid resistance and can withstand the erosion of strong acids such as sulfuric acid, hydrochloric acid and nitric acid. Acid bricks are not only corrosion-resistant, but also have the characteristics of high temperature stability, wear resistance and low water absorption, ensuring long-term stable use in harsh industrial environments. To learn more about the performance, application and selection methods of acid-resistant bricks, lütfen ziyaret edin Henan Lite.

Diğer popüler refrakter tuğlalar

- Silika tuğla

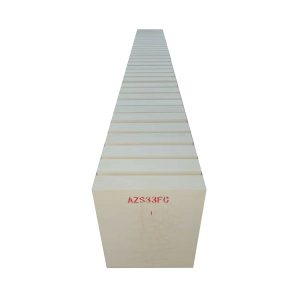

- AZS tuğlası

- Korindon tuğlası

- Magnezya krom tuğlası

- Magnezya alümina spinel tuğlası

- Yüksek alümina tuğlalar

- Kil tuğla

Refrakter Aside Dayanıklı Tuğlalar

Performance indicators of Refractory acid-resistant bricks

| index | Special acid-resistant bricks | Lightweight acid resistant brick |

| Silicon dioxide (%) ≥ | 65 | 65 |

| Toplu yoğunluk (g/m³) | 1.6-1.8 | 1.0-1.3 |

| Normal sıcaklıkta basınç dayanımı (Mpa) ≥ | 15 | 10 |

| Isı iletkenliği (W/mk) ≤ | 0.65 | 0.45 |

| Su emme (%) ≤ | 15 | 5 |

| Acid resistance rate (%) ≤ | 98 | 97 |

| Çalışma sıcaklığı(°C) ≤ | 1000 | 1000 |

Wikipedia'dan: Acid brick

Specifications of acid resistant bricks

1-Boyut:

- Standard size: usually 230mm x 114mm x 65mm (length x width x thickness)

- Other sizes: There are also specifications such as 200mm x 100mm x 50mm, 240mm x 115mm x 65mm

2-Thickness: The thickness is generally around 65mm, but there are also different thicknesses such as 40mm, 50mm, 60mm, and 80mm.

3-Shape: In addition to the common rectangular bricks, there are also special shapes of acid-resistant bricks such as round and hexagonal shapes for specific application scenarios.

4-Yüzey işleme:

- Flat surface: Most acid-resistant bricks have a smooth and flat surface.

- Concave and convex surface: Some acid bricks have a concave and convex design on the surface to increase the bonding with the mortar.

5-Renk: Common colors are white or light gray, which helps to detect any possible leaks or corrosion signs.

Acid-resistant brick price

Acid-resistant brick price

What materials are Refractory acid-resistant bricks made of?

High-alumina clay; silis; alümina; zirkonyum oksit; sodium feldspar; acid-resistant glass; acid-resistant ceramics; composite materials

When choosing the material of acid-resistant bricks, it is necessary to consider the chemical environment, sıcaklık, pressure and other factors it will face. The formula and production process of acid-resistant bricks may also be adjusted according to specific needs to meet the requirements of different application scenarios. These conditions can be met by our Henan Lit Refractory Materials. Welcome to order and guarantee to provide you with high-quality acid-resistant brick products.

Acid-resistant and alkali-resistant bricks VS acid-resistant bricks

Different material composition: Acid-resistant bricks are usually made of high-alumina clay, silica and other materials, and focus on resisting corrosion from acidic substances. Acid-resistant and alkali-resistant bricks are designed to resist corrosion from both acidic and alkaline substances. They usually use more complex formulas and may contain ingredients such as alumina, magnezyum oksit, and calcium oxide to enhance their alkali resistance.

Different performance: Refractory Acid bricks mainly emphasize their tolerance to acids, but their resistance to alkaline environments is relatively weak. Acid-resistant and alkali-resistant bricks are more comprehensive in chemical stability, and can withstand both strong acid erosion and strong alkali corrosion. Acid-resistant and alkali-resistant bricks may also have higher high temperature resistance because they need to remain stable in a wider range of chemical environments.

Different application scenarios: Acid-resistant bricks are often used in purely acidic environments, such as acid storage tanks and trenches in chemical plants. Acid-resistant and alkali-resistant bricks are suitable for use in situations where the types of chemicals are complex and acids and alkalis coexist, such as certain chemical reactors and sewage treatment facilities. Which brick to choose depends on the specific industrial environment and the type of chemical.

How to maintain acid-resistant bricks

- Regularly check the surface of acid-resistant bricks for cracks, damage or signs of wear.

- Check the brick joints for acidic substances and ensure that there are no gaps between the mortar and the brick body.

- Use clean water or neutral detergent to clean the surface of Refractory acid-resistant bricks. Avoid using strong acid or strong alkaline detergents to avoid damaging the acid resistance of the brick body.

- Remove chemicals, dirt or debris that may have accumulated on the brick surface.

- Repair any cracks or damage found, using acid-resistant mortar or repair materials that match the original brick material.

- For small areas of damage, acid-resistant glue can be used for repair.

- Ensure that the surface of acid bricks will not be exposed to large amounts of acidic substances for a long time. If necessary, clean and rinse in time.

- Kullanım sırasında, avoid acidic liquids staying on the brick surface for a long time.

- Try to avoid exposing acid-resistant bricks to extreme temperatures, as excessive temperature changes may cause the brick body to expand or contract, affecting its structural stability.

- In highly corrosive environments, you can consider applying a protective coating on the surface of Refractory acid-resistant bricks to further enhance their corrosion resistance.

- Prevent heavy objects from directly hitting or scratching the surface of acid bricks to avoid mechanical damage.

- Strictly control the use and storage of chemicals to prevent chemical leakage or spillage from causing unnecessary corrosion to acid-resistant bricks.

- For large facilities or complex application scenarios, it is recommended to hire professionals for regular maintenance and inspection.

Acid-resistant brick specifications

Acid-resistant brick specifications

Yorumlar

Henüz yorum yok.