Tanım

Refrakter çimento Açıklama

Refrakter çimento, hammadde olarak yüksek kaliteli boksit ve kireçten yapılmıştır, uygun bileşenlerle hammaddelere belirli oranda karıştırılarak üretilir.. Sinterlemeden sonra, ana bileşeni alüminat olan klinker, refrakter hidrolik çimentolu malzeme yapmak için ince toz halinde öğütülür. Genellikle refrakter çimento ile karıştırılır

Diğer şekilsiz ürünler

- Refrakter dökülebilir

- Tokmaklama refrakterleri

- Refrakter plastik

- Refrakter harç

- Refrakter agrega

- Refrakter boksit

- magnezyum püskürtme malzemesi

Tteknik Parametre

| Öğe | CA-50 Çimento | CA-60 Çimento | CA-70 Çimento | CA-80 Çimento | |

| Kimyasal bileşen | AL2O3% | 50-60 | 60-68 | 68-77 | 77 |

| SIO2 /% | 8.0 | 5.0 | 1.0 | 0.5 | |

| FE2O3/% | 2.5 | 2.0 | 0.7 | 0.5 | |

| R2O(Na2o+0.658K20)/% | 0.4 | 0.4 | 0.4 | 0.4 | |

| Kopma mukavemeti(MPa) | 1gün | 5.5 | 2.5 | 5.0 | 4.0 |

| 3günler | 6.5 | 5.0 | 6.0 | 5.0 | |

| 28günler | / | 10.0 | / | / | |

| Basınç dayanımı(MPa) | 1gün | 40 | 20 | 30 | 25 |

| 3gün | 50 | 45 | 40 | 30 | |

| 28günler | / | 80 | / | / | |

| Zamanın ayarlanması (Min) | Başlangıç zamanı | 30 | 60 | 30 | 30 |

| Son zaman | 360 | 1080 | 360 | 360 | |

Refrakter çimento üretim süreci

A[Hammadde alımı] –> B[Hammadde hazırlama] –> C[İçindekiler] –> D[karışım] –> e[Bileme] –> F[Ateş etme] –> G[sakin ol] –> H[Ezici] –> BEN[filtre] –> J[Paket] –> k[Bitmiş Ürün] –> L[mağaza] –> M[toplu taşıma]

- Hammadde alımı: yüksek alüminalı çimento gibi hammaddelerin tedariki, refrakter agrega, ince agrega, katkı maddeleri, vesaire.

- Hammadde hazırlama: Hammaddeleri ön işleme tabi tutun, tarama gibi, temizlik, kurutma, vesaire.

- harmanlama: Çeşitli hammaddeleri tarif oranına göre doğru şekilde tartın.

- Karıştırma: Tartılan malzemeleri eşit şekilde karıştırın.

- Bileme: Reaksiyon alanını arttırmak için karışık malzemeleri ince toz halinde öğütün.

- Ateş etme: Malzemenin kimyasal reaksiyona girmesini sağlamak ve refrakter çimentonun kristal yapısını oluşturmak için yüksek sıcaklıkta sinterleme.

- Soğutma: Sinterlenmiş malzemenin oda sıcaklığına soğutulması gerekiyor.

- Ezici: Soğutulan malzeme ince toz haline getirilir.

- Tarama: Parçacık boyutunun gereksinimleri karşıladığından emin olmak için tarama kullanılır.

- Ambalajlama: Nitelikli ürünleri paketleyin ve satışa veya depolamaya hazırlayın.

- Bitmiş ürün: Son refrakter çimento ürünü.

- Depolamak: Ürün kuru ve havalandırılmış bir depoda saklanmalıdır.

- Toplu taşıma: Ürünleri sipariş gereksinimlerine göre müşterilere ulaştırmak.

3000 Dereceli dökülebilir refrakter çimento

Refrakter çimento VS refrakter harç

Refrakter çimento:

- Kompozisyon: Esas olarak alüminat çimentosundan oluşur, yüksek alüminalı çimento veya iyi refrakter özelliklere sahip diğer çimento, ve bazı refrakter agregalar eklenebilir.

- Başvuru: Genellikle yüksek sıcaklık dayanımının gerekli olduğu yerlerde kullanılır, kazanlar gibi, fırınlar, bacalar, vesaire. Dökmek veya püskürtmek için kullanılabilir.

- karakteristik:

- Yüksek sıcaklık dayanımı (genellikle 1000°C'nin üzerinde).

- Hızlı katılaşma.

- Yüksek mukavemet ve yüksek basınç dayanımı.

- İyi kimyasal direnç.

- Kullanım kısıtlamaları: Maliyetinin yüksek olması nedeniyle, genellikle kritik alanlarda veya hızlı onarımların gerekli olduğu yerlerde kullanılır.

Refrakter çimento

Refrakter harç:

- Kompozisyon: Esas olarak refrakter malzemelerden oluşur (refrakter kil gibi, alüminyum silikat, vesaire.) çimento veya diğer bağlayıcılarla karıştırılmış. Farklı oranlar farklı refrakter gereksinimlerini karşılayabilir.

- Başvuru: Esas olarak refrakter tuğlalar arasındaki derzlerde kullanılır, refrakter levhalar ve diğer malzemeler, ve aynı zamanda refrakter kaplamalar için de kullanılabilir.

- karakteristik:

- Yangına dayanıklılık formüle göre farklı sıcaklıklara ulaşabilir, ancak genellikle refrakter çimento kadar yüksek değildir.

- Güçlü bağlanma gücü, duvar işlerine uygun.

- Kolay inşaat, iyi akışkanlık, boşlukları doldurmak kolay.

- Nispeten zayıf kimyasal direnç.

- Kullanım kısıtlamaları: Yapışkanlığı ve akışkanlığı nedeniyle, nispeten düşük sıcaklıktaki ortamlar için veya yardımcı malzeme olarak uygundur.

- Refrakter çimento, yüksek mukavemet ve yüksek sıcaklık dayanımı gerektiren yapısal parçalar için daha uygundur., fırın gövdesinin içindeki döküm gibi.

- Refrakter harç esas olarak duvarcılıkta ve malzemeler arasında yapışma sağlamak amacıyla boşlukların doldurulmasında kullanılır..

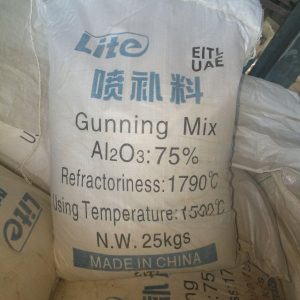

Refrakter Çimento 25kg

Refrakter çimento kullanımları

- Yüksek sıcaklık fırınları: astarlamak için kullanılır, fırınların duvar işleri ve onarımı

- Metalurji: izabe fırınlarının astarlanması ve onarımı için kullanılır, dönüştürücüler, elektrikli fırınlar ve diğer ekipmanlar

- Kimya endüstrisi: Kimyasalların astarlanması ve onarılmasında kullanılır, depolama tankları, boru hatları ve diğer ekipmanlar

- İnşaat sektörü: Yüksek sıcaklık ortamlarındaki binalar için kullanılır, yüksek fırınlar gibi, elektrikli fırınlar, çelik fabrikaları, alüminyum tesisleri, vesaire.

- Elektrik enerjisi endüstrisi: pastırma üretiminde kullanılır, kazanlar ve brülörler, vesaire.

Case Studies of refractory Cement

Refractory cement packing and delievery

Yorumlar

Henüz yorum yok.