- Uy

- Shisha sanoati

Shisha sanoati

Yechim

Shisha kilogqa kirish

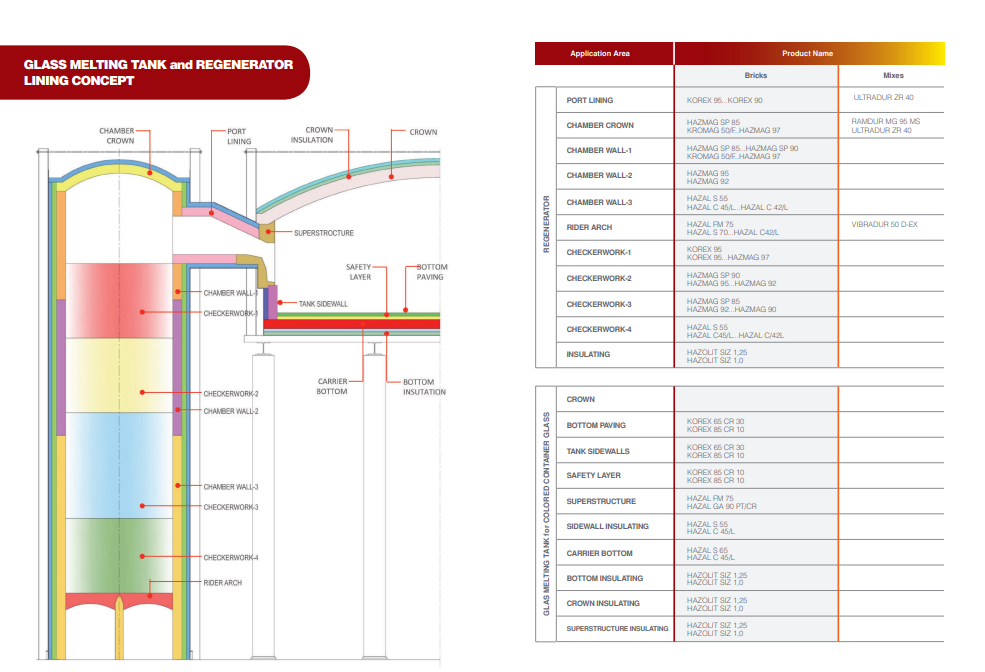

Shisha kvadrat - bu shisha ishlab chiqarish uchun maxsus ishlatiladigan uskunalar. Odatda o'choq tanasidan iborat, yonboshlamoq, Haroratni boshqarish tizimi, Uzatish moslamasi va shisha mahsulotning chiqish joyi. Olov tanasining ichki qismi ham izolyatsiya qatlamini o'z ichiga oladi, Yuvish kamerasi, Shisha basseyn va boshqa qismlar. Sovakka oid materiallar shisha eritilgan pechning muhim tarkibiy qismidir. Ular shisha sifatida hal qiluvchi rol o'ynaydi, Energiya sarfi va mahsulot narxi.

Shisha kilogramm tasnifi

- Bu Temperli shisha pech ma'lum bir haroratda oddiy tekis shisha yoki laminatlangan stakanni qizdiradigan pech, va keyin stakan sirtini siqish uchun stakan sirtini siqish holatiga olib borish. Temperli shisha pechning stakanida singandan keyin yuqori siqish kuchi va kichik zarrachalar xususiyatlari mavjud. U yuqori xavfsizlik va keng dasturlash oralig'iga ega. Yaxshi shisha pechning og'irligi haroratni boshqarish va yuqori ishlab chiqarish samaradorligi bilan tavsiflanadi.

- Suzuvchi shisha pechkasi Yassi stakan ishlab chiqarish uchun ishlatiladigan uskunaning bir qismi. Shisha xom ashyosi yumshatilgan holatga qizdiriladi, Tin vannada suzib ketdi va keyin shakllanish uchun sovutildi. Fallat stakanining ishlab chiqarish jarayoni yuqori haroratda amalga oshirilishi va yuqori ishlab chiqarish samaradorligi xususiyatlariga ega bo'lishi kerak, Tez ishlab chiqarish tezligi va bir xil shisha buyumlarning sifati.

Shisha pechka tarkibi

Shaktlar oshpazining asosiy tarkibiy qismlari issiqlik saqlash joyi kamerasini o'z ichiga oladi, Tekshirgich g'isht, Havo va o't o'chirish bo'limlari, izolyatsion g'isht, va hokazo. Issiqlik vaqtincha kamerasi davriy issiqlik almashinuvi uskunalari, bu davriy barqaror bo'lmagan harorat maydoniga tegishli, va issiqlik uzatish jarayoni beqaror issiqlikni o'tkazmaydi. Cheklovchining g'isht - bu issiqlik saqlash kamerasining yadro tarkibiy qismi, Issiqlikni saqlash va bo'shatish uchun javobgar. Havo va o't o'chirish bo'limining devori havo issiqlik va gazni saqlash kamerasi orasidagi qismidir. Chunki yuqori harorat juda yuqori va parvozli material eroziyasi mavjud, Yonayotgandan keyin yong'in chiqishi oson, Shunday qilib, uning qalinligi umuman katta va qattiq masonlar talab etiladi. Izolyatsiya g'ishtlari issiqlik saqlash kamerasining tashqi devorining issiqlik yo'qolishini kamaytirish uchun ishlatiladi.

Shisha kilog 'kilog' printsipi

Shaktlar pechasining ish printsipi asosan issiqlik o'tkazilishini o'z ichiga oladi, Momerum uzatish va ommaviy uzatish. Issiqlikni uzatish alangada va shisha suyuqlikdagi harorat farqidan kelib chiqadigan alangali bo'shliqlar almashinuvini o'z ichiga oladi, Shisha suyuqlikda issiqlik almashinuvi, Issiqlik saqlash kamerasida issiqlik almashinuvi, va pechning devori va tashqi muhit o'rtasidagi issiqlik almashinuvi. Momiyal o'tkazuvchanlik bosim farqidan kelib chiqadi, va ommaviy transfer kimyoviy reaktsiyalar va kompozitsiyani shisha suyuqlikda o'zgartiradi.

Shaktlar kabeli va echimlari keng tarqalgan kamchiliklar va echimlar

1. O'choq boshidan chiqolmaydi

Sabab

Olovning harorati juda past

Tomog 'studidagi harorat past

Juda ko'p chayqalishlar to'sqinlik qiladi

Yechim

Yoqilg'i ta'minotini ko'paytiring va pechning haroratini oshiring

Yuvish vaqtini va bo'sh joyini sozlang, improve air guide conditions, and increase kiln throat outlet temperature

Clean up slag, adjust raw material ratio, and reduce slag generation

2. Kiln damage

Sabab

Chemical erosion: The glass liquid is rich in silica, which has serious chemical erosion on the kiln lining material

Mechanical scouring: Strong scouring of glass liquid flow and materials

High temperature effect: The working temperature of the kiln pool is as high as 1600 dog ', and the temperature of each part fluctuates greatly

Yechim

Select refractory materials that can resist erosion, such as AL2O3ZrO2-SiO2 series of fused bricks

Select high-strength and scouring-resistant refractory materials

Materials that are resistant to high-temperature erosion and do not pollute the glass liquid

3. Problems with SCR denitrification process in kilns

Causes

Degradation of catalyst performance

Ammonia supply problems

Difficulty in equipment maintenance

Wastewater treatment problems

Solutions

Regularly replace catalysts, optimize operating conditions, and use special cleaning agents

Improve ammonia storage and transportation systems, and develop new ammonia sources

Use more durable materials and designs, and provide professional maintenance training

Use advanced wastewater treatment technologies such as reverse osmosis or evaporation

4. Other common kiln failures

Causes and solutions

| Fault phenomenon | Cause | Yechim |

|---|---|---|

| Large temperature indication error | Thermocouple is blocked or burned by material | Clean up the accumulated material or replace the thermocouple |

| Pressure indication is low | The pressure measuring tube is blocked by dust or the cyclone is filled with material. | Use compressed air to blow out the pressure gauge or cyclone cone |

| Running raw material | The temperature at the kiln tail drops too much, the coal feeding amount is too little, va hokazo. | Reduce feed, reduce kiln speed, add coal appropriately |

What alarm should be set for the glass furnace air cooling protection system

- Temperature alarm device: During the production process of glass kilns, the temperature may be too high due to the influence of the environment. In order to avoid damage to equipment and production safety problems caused by excessive kiln temperature, a temperature alarm device should be set. Once the kiln temperature exceeds the set value, an alarm can be issued in time.

- Air flow monitor: During the production process, glass kilns pay great attention to the control and regulation of air flow. If the air flow is insufficient, the glass raw materials are not fully melted. A high amount of air is required to keep the glass kiln running for a long time. The air flow monitor can monitor and control the air volume. Once there is a problem with the air flow, an alarm will be issued.

- Oxygen detector: During the glass production process, gas combustion in the kiln requires a certain amount of oxygen. If the oxygen is insufficient, it will lead to problems such as reduced glass production and reduced quality. Shuning uchun, an oxygen detector should be installed to monitor the oxygen concentration in real time and issue an alarm in time.