Tavsif

What are magnesia carbon bricks?

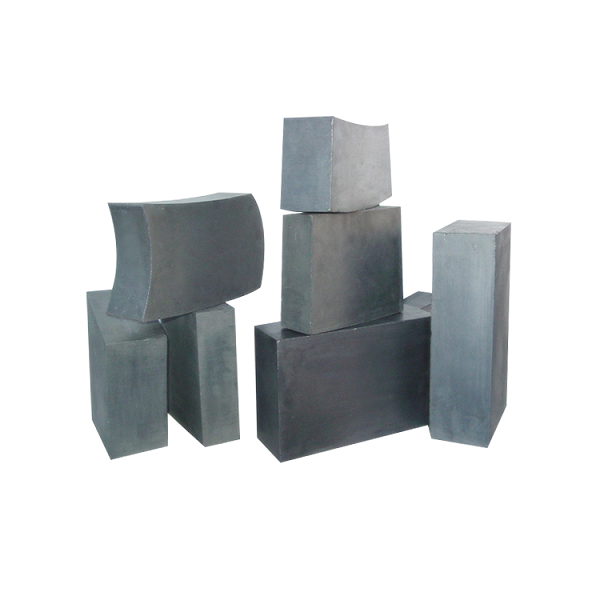

Magnesia Carbon Brick is a high-performance refractory material, mainly used in high-temperature industrial environments such as steel, ironmaking, glassmaking, va hokazo. Its main components include magnesia (magnesium oxide, MgO) and carbonaceous materials (such as graphite, koks), and antioxidants and binders may also be added. Magnesia Carbon Brick has extremely high refractoriness, korroziyaga qarshilik, thermal stability and mechanical strength, and is suitable for furnace lining materials under high temperature conditions, such as converters, electric arc furnaces, ladles, va hokazo. Through precise proportioning and advanced manufacturing processes, Magnesia Carbon Brick can provide excellent durability and performance, and is an indispensable material in modern high-temperature industries.

The national standard number of magnesia carbon bricks is GB/T 22589. The Chinese name of the standard is “magnesiya uglerod g'ishtlari” and the English name is “Magnesia carbon bricks”.

Other Magnesia Bricks

Magnesia carbon bricks composition

Magnesiya: 50-80%

Carbon material: 10-20%

Antioxidant: 2-5%

Binder: 3-6%

Other additives: depending on specific needs

Texnik parametr

| Name of product | Brend | Kimyoviy tarkibi | AP%≥ | BD g/cm3≥ | CCS,Mpa | 1400℃×30min≥MOR,Mpa | |

| MgO≥ | C≥ | ||||||

| Magneziya uglerod g'isht | MT10A | 80 | 10 | 4 | 2.90 | 40 | 6 |

| MT10B | 78 | 10 | 5 | 2.85 | 35 | 5 | |

| MT10C | 76 | 10 | 6 | 2.80 | 30 | 4 | |

| MT14A | 76 | 14 | 4 | 2.90 | 40 | 12 | |

| MT14B | 76 | 14 | 5 | 2.82 | 35 | 8 | |

| MT14C | 74 | 14 | 6 | 2.77 | 25 | 5 | |

| MT18A | 72 | 18 | 3 | 2.90 | 40 | 10 | |

| MT18B | 70 | 18 | 4 | 2.82 | 35 | 7 | |

| MT18C | 70 | 18 | 5 | 2.77 | 35 | 4 | |

| Tap hole brick | MTK-74 | 74 | 16 | 4 | 2.9 | 30 | – |

Vikipediyadan:xavf ostiga qo'yish、Refrakter

Production process of mag carbon brick

- Xom ashyo tanlash: 98% sintered magnesia, 91% fused magnesia and natural flake graphite with a fixed carbon content of 94-95% and an ash content of 5%

- Raw material processing: crush and screen the sintered magnesia and fused magnesia blocks respectively, and grind part of the sintered magnesia into fine powder less than 0.088mm through a cylinder mill as a mixing material

- Partiya: prepare the raw materials according to a predetermined ratio

- Aralashtirmoq: mix in a strong sand mixer, and the order of adding materials is: magnesia aggregate-binder-graphite-fine powder and additives, and the mixing time is 15-45min

- Qolip: use a molding machine to press the mixed raw materials into shape

- Drying and firing: dry and fire the molded magnesia carbon bricks to improve their strength and stability

How much does magnesite carbon bricks cost per ton

On December 17, 2024, according to the latest market trends, the price of magnesia carbon bricks in Liaoning Province has shown a stable and strong trend in the near future. Especially for 12A and 14A magnesium carbon bricks in the ladle slag line, the prices are stable at 5,100 yuan/ton and 5,300 yuan/ton respectively. No specific values are provided for other regions, please refer to the above data.

Magnesia carbon bricks for ladle slag line

Magnesia Carbon Bricks price

Raw material cost, manufacturing process, brand and quality, specifications and dimensions, market supply and demand, transportation and logistics costs, taxes and tariffs, order volume

- Ordinary magnesium carbon bricks: the price may range from several thousand to ten thousand yuan per ton.

- High-performance magnesium carbon bricks: the price may range from ten thousand to twenty thousand yuan per ton or even higher.

Magnesia carbon bricks uses

1-Chelik sanoati:

Converter: Magnesia carbon bricks are often used in the bottom, wall and mouth of the converter, resistant to high temperature and slag erosion.

Electric arc furnace: In the electric arc furnace, magnesium carbon bricks are used as lining materials to resist the thermal shock of the arc and the erosion of slag.

Ladle: Magnesia carbon bricks are used as ladle lining to protect the quality of molten steel during transportation and pouring.

2-Ironmaking industry:

Blast furnace: Magnesium carbon bricks can be used for the body and bottom of the blast furnace to resist high temperature and erosion.

Non-ferrous metal smelting: Magnesium carbon bricks are used for the lining of non-ferrous metal smelting furnaces such as aluminum and copper to provide refractory protection.

3-Shisha sanoati: Magnesium carbon bricks can be used in certain parts of glass melting furnaces to provide high temperature and erosion resistance.

4-Tsement sanoati: In cement rotary kilns, magnesium carbon bricks are used in certain high-temperature parts, such as transition zones and burning zones.

5-Waste incinerator: Due to its high temperature resistance and erosion resistance, magnesium carbon bricks are also used for the lining of waste incinerators.

6-Other high-temperature industries: Magnesium carbon bricks can also be used in other industries that require high temperature resistance, erosion resistance and mechanical strength, such as ceramic manufacturing, chemical reactors, va hokazo.

mag carbon brick for converter

Packing

(1)Carton packaging .

(2)tray + plastic film + fixed band .

(3)pallets: 1*1m,0.93*0.93m .

(4)tray weight: 1.6~2.0ton.

(5)packaging according to customer service requirements .

Sharhlar

Hali ham sharhlar yo'q.