Sự miêu tả

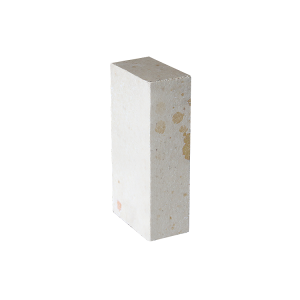

1.Fire clay brick Description

Fire Clay bricks are refractory bricks made of various raw materials including refractory clay, calcined soft clay and soft clay. The alumina content is generally 30% -48% alumina refractory. It is a weakly acidic refractory product that can resist acid slag and acid gas erosion, has good thermal performance, and is resistant to rapid cooling and high temperature.

Other refractory bricks

- Gạch alumina cao

- gạch Mullite

- Gạch magie

- Gạch Spinel Magnesia alumina

- Gạch crôm magiê

- Gạch cacbon magie

- Gạch corundum

- Gạch Azs

- Gạch silic

- Gạch silic cacbua chịu lửa

- Gạch neo chịu lửa

- Gạch Silicon Mullite chịu lửa

- Gạch chịu lửa chịu axit

2.Fire clay brick Feature

(1)High refractoriness

(2)High-temperature endurable

(3)Good corrosion resistance

(4)Good spalling resistance and wear resistance

(5)Good thermal shock resistance

(6)High mechanical strength

(7)Good volume stability at high temperature.

3.Thông số kỹ thuật

| SK series | SK30 | SK32 | SK34 | SK35 |

| AL2O3 | 30%-35% | 35%-38% | 38%-42% | 42%-50% |

| Fe2o3 /% | ≤ 3 | ≤ 3 | ≤ 3 | ≤ 2.5 |

| Tính khúc xạ | ≥ 1690 oC | ≥ 1730℃ | ≥ 1750℃ | ≥ 1750℃ |

| B.D/g/cm3 | 1.9-2.0 | 2.0-2.1 | 2.1-2.18 | 2.15-2.3 |

| Unit weight(230*114*65mm) | ≥ 3.35KGS | ≥ 3.55KGS | ≥ 3.65KGS | ≥ 3.75KGS |

| A.P% | ≤ 26 | ≤ 24 | ≤ 24 | ≤ 22 |

| C.C.S | ≥ 20Mpa | ≥ 25Mpa | ≥ 30Mpa | ≥ 35Mpa |

| R.U.L | ≥ 1250 oC | ≥ 1300 oC | ≥ 1350 oC | ≥ 1420 oC |

| R.L.C% | 0~ -0.5(1350oC ,2h) | 0~ -0.3(1350oC ,2h) | 0~ -0.4(1450oC ,2h) | +0.1~ -0.4(1450oC ,2h) |

Từ Wikipedia: Gạch chịu lửa

Đánh giá

Chưa có đánh giá nào.