Sự miêu tả

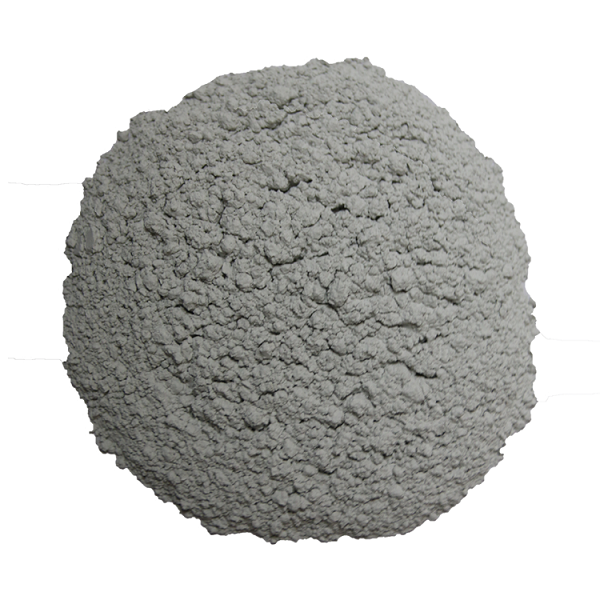

Xi măng chịu lửa Mô tả

Xi măng chịu lửa được làm từ bauxite và vôi chất lượng cao làm nguyên liệu, và được trộn vào nguyên liệu có thành phần thích hợp theo tỷ lệ nhất định.. Sau khi thiêu kết, clinker với thành phần chính là aluminate được nghiền thành bột mịn để tạo ra vật liệu xi măng thủy lực chịu lửa. Thường trộn với xi măng chịu lửa

Các sản phẩm không định hình khác

- Vật liệu chịu lửa đúc được

- Đâm vật liệu chịu lửa

- Nhựa chịu lửa

- Vữa chịu lửa

- cốt liệu chịu lửa

- bauxite chịu lửa

- vật liệu bắn magiê

Tkỹ thuật Pthông số

| Mục | Xi măng CA-50 | Xi măng CA-60 | Xi măng CA-70 | Xi măng CA-80 | |

| Thành phần hóa học | AL2O3% | 50-60 | 60-68 | 68-77 | 77 |

| SIO2 /% | 8.0 | 5.0 | 1.0 | 0.5 | |

| FE2O3/% | 2.5 | 2.0 | 0.7 | 0.5 | |

| R2O(Na2o+0,658K20)/% | 0.4 | 0.4 | 0.4 | 0.4 | |

| Sức mạnh vỡ(MPa) | 1ngày | 5.5 | 2.5 | 5.0 | 4.0 |

| 3ngày | 6.5 | 5.0 | 6.0 | 5.0 | |

| 28ngày | / | 10.0 | / | / | |

| Cường độ nén(MPa) | 1ngày | 40 | 20 | 30 | 25 |

| 3ngày | 50 | 45 | 40 | 30 | |

| 28ngày | / | 80 | / | / | |

| Thời gian cài đặt (Tối thiểu) | Thời gian ban đầu | 30 | 60 | 30 | 30 |

| Lần cuối cùng | 360 | 1080 | 360 | 360 | |

Quy trình sản xuất xi măng chịu lửa

MỘT[Mua sắm nguyên liệu thô] –> B[Chuẩn bị nguyên liệu] –> C[Thành phần] –> D[trộn] –> E[mài] –> F[Bắn] –> G[hạ nhiệt] –> H[Nghiền] –> TÔI[lọc] –> J[Bưu kiện] –> K[thành phẩm] –> L[cửa hàng] –> M[vận tải]

- Mua sắm nguyên liệu thô: thu mua nguyên liệu thô như xi măng có hàm lượng alumina cao, cốt liệu chịu lửa, cốt liệu mịn, phụ gia, vân vân.

- Chuẩn bị nguyên liệu: sơ chế nguyên liệu thô, chẳng hạn như sàng lọc, dọn dẹp, sấy khô, vân vân.

- trộn: Cân chính xác các nguyên liệu thô khác nhau theo tỷ lệ công thức.

- Trộn: Trộn đều các vật liệu đã cân.

- mài: Nghiền các vật liệu đã trộn thành bột mịn để tăng diện tích phản ứng.

- Bắn: thiêu kết ở nhiệt độ cao để làm cho vật liệu trải qua phản ứng hóa học và tạo thành cấu trúc tinh thể của xi măng chịu lửa.

- làm mát: Vật liệu thiêu kết cần được làm nguội đến nhiệt độ phòng.

- Nghiền: Vật liệu nguội được nghiền thành bột mịn.

- Sàng lọc: Sàng lọc được sử dụng để đảm bảo kích thước hạt đáp ứng yêu cầu.

- Bao bì: Đóng gói các sản phẩm đủ tiêu chuẩn và chuẩn bị để bán hoặc lưu trữ.

- thành phẩm: Sản phẩm xi măng chịu lửa cuối cùng.

- Kho: Sản phẩm nên được bảo quản ở nơi khô ráo, thoáng mát.

- Vận tải: Vận chuyển sản phẩm đến tận tay khách hàng theo yêu cầu đặt hàng.

3000 Xi măng chịu lửa đúc được độ

Xi măng chịu lửa VS vữa chịu lửa

Xi măng chịu lửa:

- Thành phần: Chủ yếu bao gồm xi măng aluminate, xi măng có hàm lượng alumina cao hoặc xi măng khác có đặc tính chịu lửa tốt, và một số cốt liệu chịu lửa có thể được thêm vào.

- Ứng dụng: Thường được sử dụng ở những nơi cần chịu nhiệt độ cao, chẳng hạn như nồi hơi, lò nung, ống khói, vân vân. Có thể dùng để đổ hoặc phun.

- đặc trưng:

- Điện trở nhiệt độ cao (thường trên 1000°C).

- kiên cố hóa nhanh.

- Cường độ cao và cường độ nén cao.

- Kháng hóa chất tốt.

- Hạn chế sử dụng: Do chi phí cao, nó thường được sử dụng ở những khu vực quan trọng hoặc nơi cần sửa chữa nhanh chóng.

Xi măng chịu lửa

Vữa chịu lửa:

- Thành phần: Nó chủ yếu bao gồm các vật liệu chịu lửa (chẳng hạn như đất sét chịu lửa, nhôm silicat, vân vân.) trộn với xi măng hoặc chất kết dính khác. Tỷ lệ khác nhau có thể đáp ứng các yêu cầu vật liệu chịu lửa khác nhau.

- Ứng dụng: Chủ yếu được sử dụng cho các mối nối giữa gạch chịu lửa, tấm chịu lửa và các vật liệu khác, và cũng có thể được sử dụng cho lớp phủ chịu lửa.

- đặc trưng:

- Khả năng chống cháy có thể đạt đến nhiệt độ khác nhau theo công thức, nhưng nó thường không cao bằng xi măng chịu lửa.

- Sức mạnh liên kết mạnh mẽ, thích hợp cho công việc xây dựng.

- Dễ dàng xây dựng, tính lưu loát tốt, dễ dàng lấp đầy khoảng trống.

- Kháng hóa chất tương đối kém.

- Hạn chế sử dụng: Do tính kết dính và tính lưu loát của nó, nó phù hợp với môi trường nhiệt độ tương đối thấp hoặc làm vật liệu phụ trợ.

- Xi măng chịu lửa phù hợp hơn cho các bộ phận kết cấu đòi hỏi cường độ cao và khả năng chịu nhiệt độ cao, chẳng hạn như việc đúc bên trong thân lò.

- Vữa chịu lửa chủ yếu được sử dụng để xây và lấp đầy các khoảng trống để tạo liên kết giữa các vật liệu.

Xi măng chịu lửa 25kg

Công dụng của xi măng chịu lửa

- Lò nung nhiệt độ cao: dùng để lót, xây dựng và sửa chữa lò nung

- Luyện kim: dùng để lót và sửa chữa lò luyện kim, bộ chuyển đổi, lò điện và các thiết bị khác

- Công nghiệp hóa chất: dùng để lót và sửa chữa hóa chất, bể chứa, đường ống và các thiết bị khác

- Ngành xây dựng: sử dụng cho các công trình ở môi trường có nhiệt độ cao, chẳng hạn như lò cao, lò điện, nhà máy thép, cây nhôm, vân vân.

- Ngành điện lực: dùng để sản xuất thịt xông khói, nồi hơi và đầu đốt, vân vân.

Case Studies of refractory Cement

Refractory cement packing and delievery

Đánh giá

Chưa có đánh giá nào.