Description

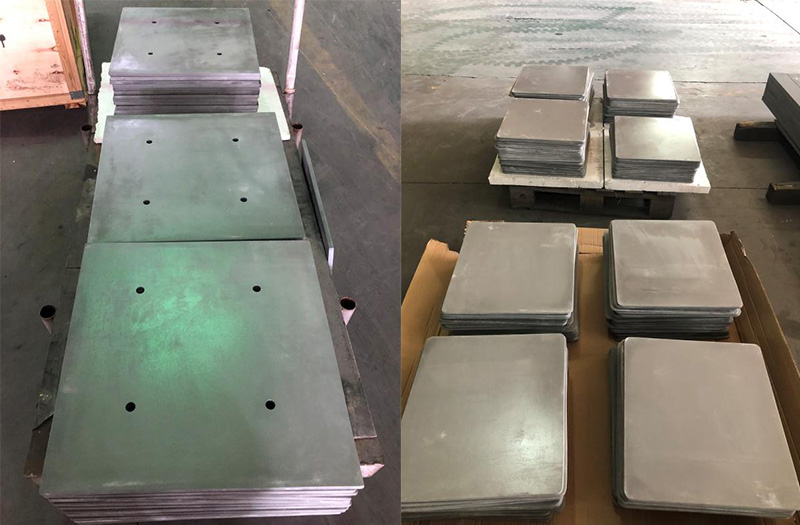

Preparation process of Nitride Bonded Silicon Carbide

Nitride Bonded Silicon Carbide uses high-purity silicon carbide powder, metal silicon powder and temporary binder. After batching, mixing, molding and drying, the silicon powder reacts with nitrogen to form silicon nitride crystal phase under high temperature and specific pressure conditions exceeding 1400 in a nitrogen atmosphere, and the silicon carbide particles are combined to form a high-temperature structural ceramic product.

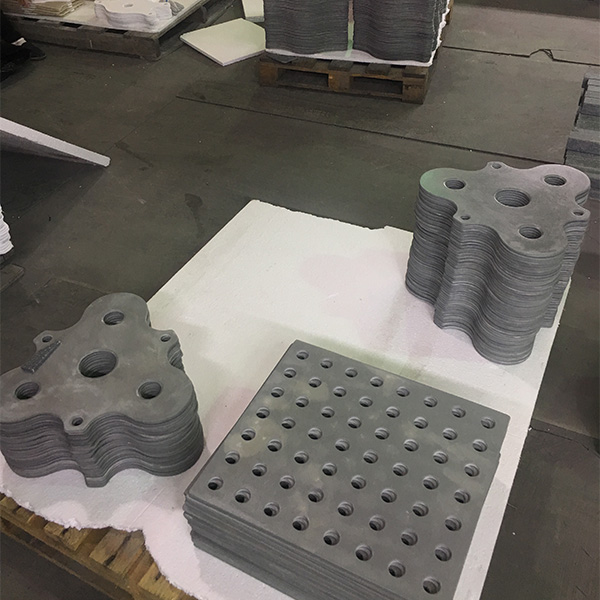

Other kiln furniture

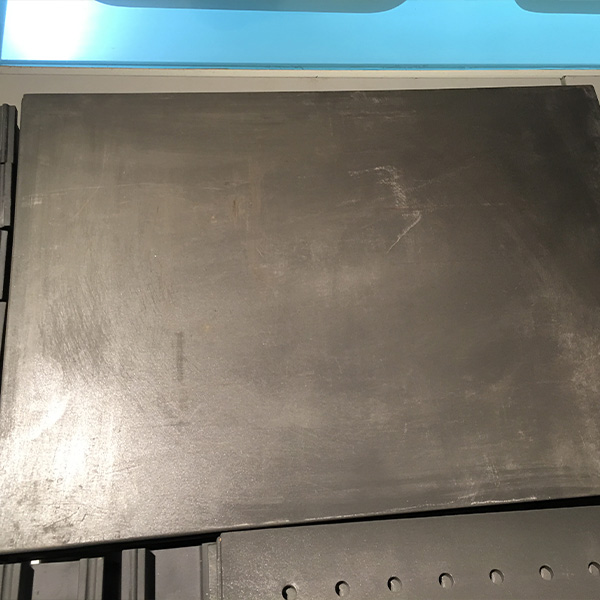

Nitride Bonded Silicon Carbide

Nitride Bonded Silicon Carbide(NBSIC) Parameter

| Item | Data | NBSIC Index |

| Bulk density | g/cm3 | ≥2.65 |

| Porosity | % | ≤18 |

| Refractoriness under load | ℃ | ≥1700 |

| Cold bending strength | Mpa | ≥40 |

| Si3N4 | % | ≥22 |

| SIC | % | ≥72 |

What are the advantages of silicon nitride combined with silicon carbide kiln furniture?

- High temperature resistance: can maintain the same strength and hardness as normal temperature at high temperature of 1200-1400℃

- High strength: high flexural strength, especially at 1400℃, it still maintains the flexural strength index at room temperature

- Good thermal conductivity: thermal conductivity is 7~8 times that of general refractory materials

- Small thermal expansion coefficient: thermal expansion coefficient is half of high aluminum refractory materials

- Good oxidation resistance: can resist oxidation at high temperature and has a long service life

- Corrosion resistance: acid and alkali corrosion resistance

Application field

Widely used in electrical porcelain, high aluminum and medium aluminum balls, grinding wheels, sanitary ware, and other special ceramic industries, oxide shelf brackets, etc.

Also used in the steel industry (for blast furnace waist lining masonry) and non-ferrous metallurgy industry (for electrolytic aluminum tank wall masonry)

Existing problems and correction directions

- Oxidation will occur during long-term use, affecting the service life of silicon nitride combined with silicon carbide kiln furniture

- Unreasonable support method is also an important reason for its damage

- Bending deformation is also an important problem of silicon nitride combined with silicon carbide kiln furniture during use

- Fragmentation will occur in an environment with temperature changes for a long time

Our website:https://www.lite-kilnrefractory.com/

Reviews

There are no reviews yet.