High alumina bricks are essential materials in various high-temperature industrial applications. Known for their excellent thermal stability, resistance to corrosion, and mechanical strength, these bricks are widely used in industries such as steel, cement, and glass manufacturing. In this article, we will delve into the specifics of SK34 high alumina brick and SK32 high alumina brick, their applications, and why they are preferred in many industrial settings.

What Are High Alumina Bricks?

High alumina bricks are refractory materials composed primarily of alumina (Al2O3) and other oxides. The alumina content typically ranges from 50% to 90%, which determines the brick’s thermal and mechanical properties. These bricks are manufactured by molding and firing raw materials at high temperatures, resulting in a dense and durable product.

SK34 High Alumina Brick

SK34 high alumina brick is a type of high alumina brick with an alumina content of around 75%. It is known for its high refractoriness, excellent thermal shock resistance, and good mechanical strength. This makes it suitable for use in high-temperature environments such as blast furnaces, cement kilns, and glass melting furnaces.

SK32 High Alumina Brick

SK32 high alumina brick, on the other hand, has a slightly lower alumina content of around 65%. It offers good thermal insulation and resistance to chemical corrosion, making it ideal for applications in steel ladles, kiln linings, and other industrial furnaces.

Applications of High Alumina Bricks

High alumina bricks are used in a variety of industrial applications due to their superior properties. Some common uses include:

- Blast furnaces

- Cement kilns

- Glass melting furnaces

- Steel ladles

- Kiln linings

Why Choose High Alumina Bricks?

High alumina bricks are preferred in many industries because of their:

- High refractoriness

- Excellent thermal shock resistance

- Good mechanical strength

- Resistance to chemical corrosion

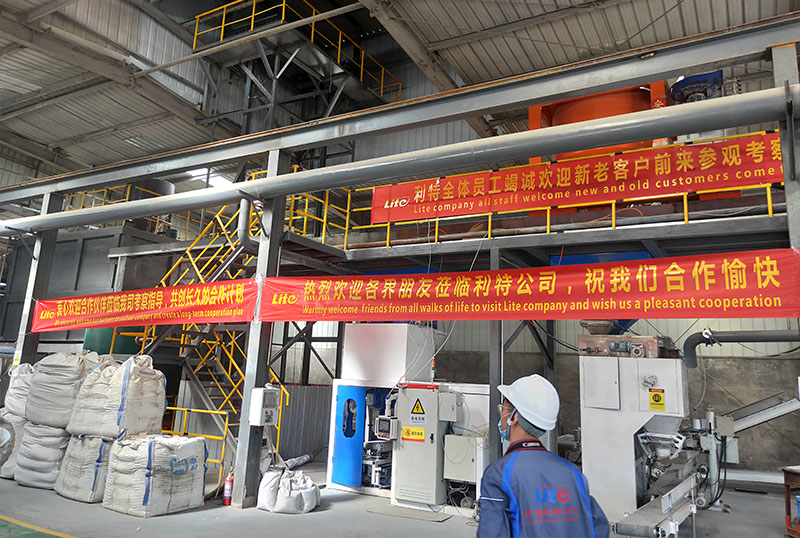

High Alumina Brick Manufacturer – Henan Lite

When it comes to sourcing high-quality high alumina bricks, Henan Lite is a trusted name in the industry. As a leading high alumina brick manufacturer, Henan Lite offers a wide range of products, including SK34 high alumina brick and SK32 high alumina brick, at competitive prices. Whether you need standard sizes or custom dimensions, Henan Lite can meet your requirements.

High Alumina Brick Price and Wholesale Options

The high alumina brick price varies depending on factors such as alumina content, size, and quantity. For bulk purchases, high alumina brick wholesale options are available, offering significant cost savings. Henan Lite provides competitive pricing and flexible wholesale options to meet the needs of industrial clients.

High Alumina Brick Sizes

High alumina bricks are available in various high alumina brick sizes to suit different applications. Standard sizes include 230mm x 114mm x 65mm, but custom sizes can also be manufactured to meet specific requirements.

Frequently Asked Questions (FAQs)

What is the difference between SK34 and SK32 high alumina bricks?

SK34 high alumina bricks have a higher alumina content (around 75%) compared to SK32 (around 65%). This makes SK34 more suitable for higher temperature applications, while SK32 offers better thermal insulation and chemical resistance.

Where can I buy high alumina bricks?

You can purchase high alumina bricks from manufacturers like Henan Lite, who offer a wide range of products at competitive prices. They also provide wholesale options for bulk purchases.

What factors affect the price of high alumina bricks?

The price of high alumina bricks is influenced by factors such as alumina content, size, and quantity. Bulk purchases often come with wholesale discounts.

Can high alumina bricks be customized?

Yes, high alumina bricks can be manufactured in custom sizes and shapes to meet specific industrial requirements. Manufacturers like Henan Lite offer customization services.