High-temperature kilns are indispensable in industries such as metallurgy, cerámica, y fabricación de vidrio. These kilns operate under extreme conditions, requiring materials that can endure intense heat and thermal shock. One such material that has proven to be highly effective is refractory ramming material. This article delves into the applications, benefits, and selection criteria of ramming mass raw material in high-temperature kilns.

What is Ramming Material?

Ramming refractory is a type of monolithic refractory material used to line the interiors of high-temperature kilns. It is composed of silica ramming mass raw material, which includes high-purity silica, alúmina, and other additives that enhance its thermal and mechanical properties. The material is typically applied manually or mechanically by ramming it into place, hence the name.

The composition of refractory ramming material varies depending on the specific application. For instance, silica ramming mass raw material is often used in applications requiring high thermal resistance, while other formulations may include magnesia or zirconia for enhanced durability.

Applications in High-Temperature Kilns

In high-temperature kilns, refractory ramming material is used to line the walls, pisos, and roofs. Its primary function is to provide insulation and protect the kiln structure from the extreme heat generated during operation. The material is particularly useful in areas where traditional bricks or castables are difficult to install or where a seamless lining is required.

One common application is in the lining of induction furnaces, where ramming mass raw material ensures uniform heating and prevents heat loss. Similarly, in glass melting furnaces, silica ramming mass raw material is used to withstand the corrosive effects of molten glass.

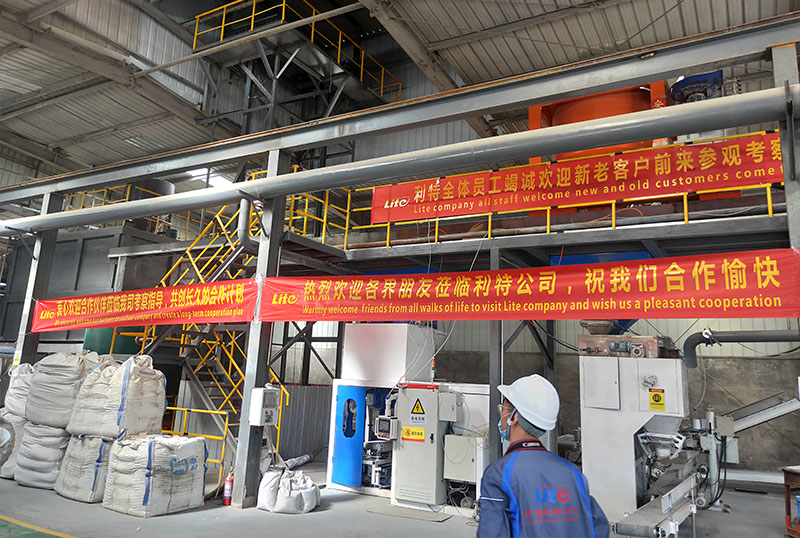

Masa de embrujos para horno de alta temperatura

Benefits of Using Ramming Material

- High Thermal Resistance: Ramming mass raw material can withstand temperatures up to 1800°C, making it ideal for high-temperature applications.

- Excellent Thermal Shock Resistance: The material can endure rapid temperature changes without cracking or spalling.

- Seamless Lining: Unlike bricks, ramming material can be applied to create a continuous, crack-free lining, reducing the risk of heat leakage.

- Ease of Application: The material can be easily rammed into place, even in complex shapes and hard-to-reach areas.

- Cost-Effective: Due to its durability and ease of installation, ramming refractory can reduce maintenance costs and extend the lifespan of kilns.

Choosing the Right Ramming Material

Selecting the appropriate ramming refractory depends on the specific requirements of the kiln. Factors to consider include the operating temperature, the type of material being processed, and the thermal and mechanical stresses the lining will endure. Silica ramming mass raw material is often preferred for its high purity and excellent thermal properties.

Al elegir refractory ramming material, it is also essential to consider the particle size distribution, as this affects the material’s packing density and thermal conductivity. Additionally, the presence of additives such as binders and stabilizers can enhance the material’s performance in specific applications.

Installation and Maintenance

The installation of ramming mass raw material requires careful preparation of the kiln surface to ensure proper adhesion. The material is typically rammed into place using pneumatic or manual tools, and it is essential to achieve a uniform density to prevent weak spots.

Regular maintenance is crucial to ensure the longevity of the lining. Esto incluye inspecciones periódicas para detectar cualquier signo de desgaste o daño y reparaciones oportunas para evitar un mayor deterioro. Manejo y almacenamiento adecuados de silica ramming mass raw material también son esenciales para mantener su calidad y rendimiento.

Conclusión

El uso de refractory ramming material en hornos de alta temperatura ofrece numerosas ventajas, incluyendo resistencia térmica mejorada, durabilidad, y facilidad de aplicación. Eligiendo el derecho ramming mass raw material, Las industrias pueden garantizar la longevidad y la eficiencia de sus hornos, en última instancia, lo que lleva a ahorros de costos y un mejor rendimiento.

Preguntas frecuentes

¿Cuál es el uso principal del material de embromado refractario??

El uso principal de refractory ramming material es alinear hornos de alta temperatura, proporcionar aislamiento y protección contra el calor extremo.

¿Por qué se prefiere la materia prima de masa de marco de sílice??

Silica ramming mass raw material se prefiere debido a su alta pureza y excelentes propiedades térmicas, making it ideal for high-temperature applications.

¿Cómo se aplica el material de embromado en los hornos??

Ramming refractory se aplica manual o mecánicamente al embromarlo en su lugar, Creando un forro sin costuras y sin grietas.

¿Cuáles son los beneficios de usar material de embrimientos sobre ladrillos tradicionales??

Usando ramming mass raw material ofrece beneficios como un revestimiento sin costuras, facilidad de aplicación, y excelente resistencia al choque térmico en comparación con los ladrillos tradicionales.

¿Cómo elijo el material de embromado adecuado para mi horno??

Al seleccionar refractory ramming material, Considere factores como la temperatura de funcionamiento, material procesado, y tensiones térmicas. Silica ramming mass raw material es a menudo una opción confiable para aplicaciones de alta temperatura.