Descripción

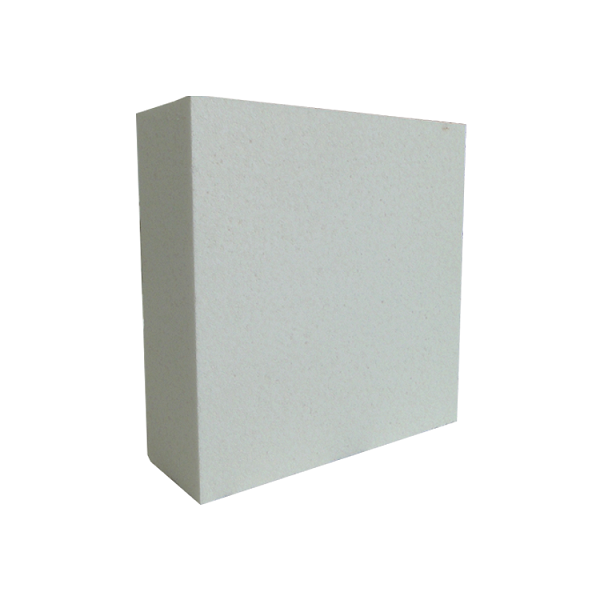

Corundum Brick Description

Corundum brick is a refractory material with alumina (Al2O3) as the main component, with a content of more than 90%. Debido a su alto punto de fusión, high hardness and high strength, it is widely used in high-temperature kiln linings and kiln furniture.

Feature

(1)High temperature resistance

(2)High strength,alta resistencia a la compresión

(3)Excellent thermal shock resistance

(4)High bulk density, buena conductividad térmica

(5)Good wear resistance and acid

(6)alkali corrosion resistance

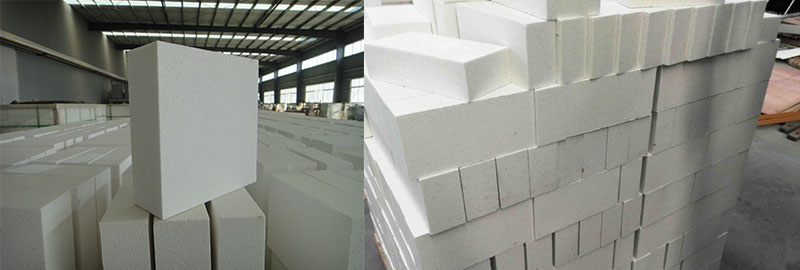

Corundum Brick

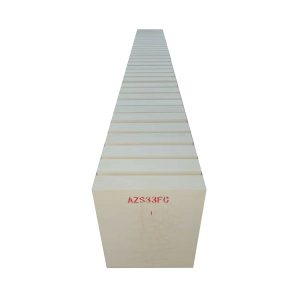

Regular size

- 230*114*65

- 250*123*65

- 171*113*65

- 230*65/55*114

- 230*114*65/55

- 230*114*65/45

- 230*114*20

- 230*57*65

- 230*150*75

- 230*150/120*75

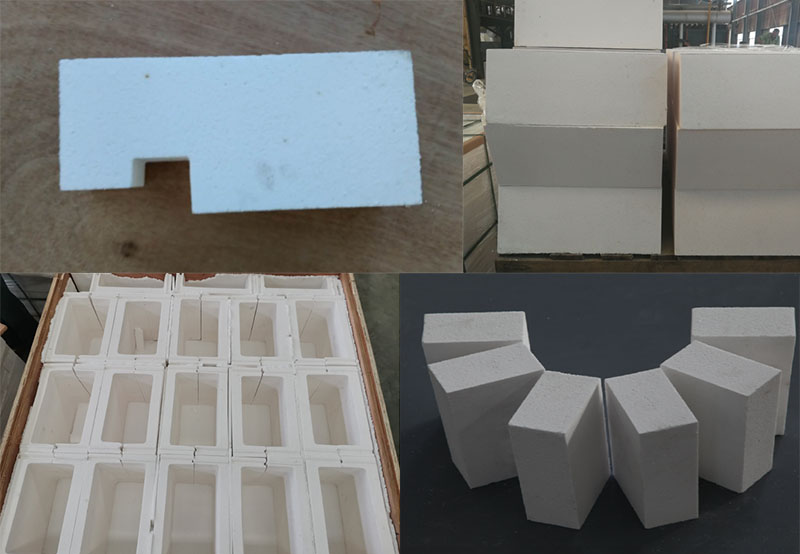

Customizable to any shape

Shape customization

Parámetro técnico

| Artículo | Corundum Brick 99 | Corundum Brick 90 | corundum mullite brick |

| Al2O3 % | ≥99 | ≥90 | ≥80 |

| SiO2 % | ≤0.2 | ≤8 | ≤18 |

| Fe2o3 % | ≤0.2 | ≤0.2 | ≤0.3 |

| Densidad aparente g/cm3 | ≥3.2 | ≥3 | ≥2.8 |

| Apparent porosity % | ≤19 | ≤18 | ≤18 |

| Cold compressive strength MPa | ≥100 | ≥100 | ≥100 |

| (0.2MPA,0.6%)Load softening began to temperature °C | ≥1700 | ≥1700 | ≥1700 |

De Wikipedia:Refractario

Proceso de producción

Sintering method: Use sintered alumina and phosphoric acid or other binders to make unburned corundum bricks.

Electrofusion method: High-purity alumina raw materials are melted and cast at a high temperature of more than 2000°C.

Henan LiTe Corundum Bricks Production Line

Production scale: 5 40 cubic shuttle kilns, 5 prensas, sistema de dosificación automático, producción diaria de 80 montones, producción anual de 20,000 montones

Proceso de producción: raw materials – crushing (0-1milímetros, 1-3milímetros, 3-5milímetros) – mixing – moldura – el secado (200℃) – sintering (1600℃-1700℃) – packaging

Production Line

Application fields of corundum bricks

1. In the steel industry;

2. In the non-ferrous smelting industry, the wear resistance and corrosion resistance of corundum bricks are significantly better than other bricks;

3. In the carbon black industry, on the carbon black reactor

4. In the petrochemical industry, in the gasification furnace of large and medium-sized fertilizer plants

Reseñas

Aún no hay reseñas.