Descripción

Overview of magnesium gunning material

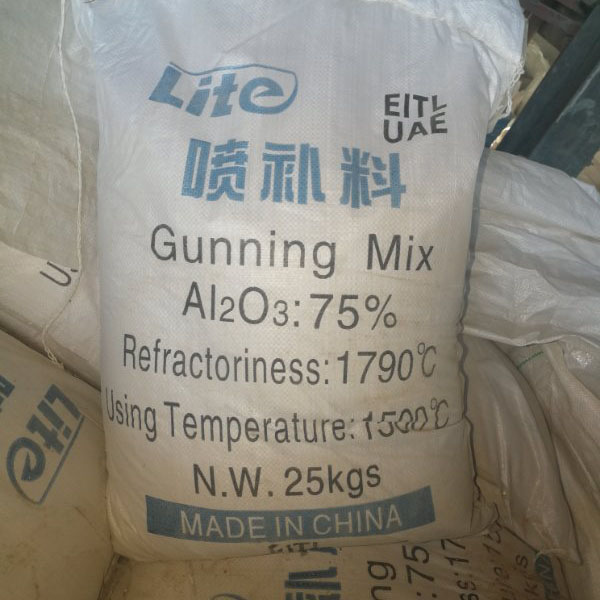

Magnesium sand spraying material is a high-performance refractory material, which is mainly composed of magnesium oxide and other auxiliary components, and has excellent fire resistance, corrosion resistance and thermal stability. Due to its excellent physical and chemical properties, magnesium sand spraying material can effectively reduce the wear of furnace lining and extend the service life of equipment during construction. Por lo tanto, it is widely used in the protection and repair of smelting furnaces, casting equipment and other high-temperature processes.

Otros productos amorfos

- Cemento refractario

- Refractarios de apisonamiento

- Plástico refractario

- Mortero refractario

- Agregado refractario

- bauxita refractaria

material de pistola de magnesio

Advantages of magnesium gunning material

- Excellent high temperature resistance

- Buena resistencia a la corrosión

- Excellent operability

- Good bonding strength

- Environmental protection performance

- Strong adaptability

Reference range of magnesium gunning material price

According to market research, the current price of magnesium aluminum spraying material is generally between 4,000 yuan and 7,000 yuan per ton. The specific price range is affected by many factors, including the technical level of the production enterprise, the purity and formula of the material, and whether there is environmental protection certification. Además, fluctuations in market demand, especially during the cyclical peak period of a specific industry, often lead to price increases.

Reference range of magnesium gunning material cost

First of all, the purchase price of raw materials is a key factor affecting the cost of magnesium spraying materials. The market price fluctuations of raw materials such as magnesia sand and magnesium powder will directly affect the cost of the final product. Además, the price difference of raw materials of different qualities will also significantly change the production cost. According to market data, the raw material cost of magnesium spraying materials generally accounts for 40% a 60% of the total cost.

Secondly, different production processes will also lead to changes in costs. Efficient production processes and advanced equipment can improve the production efficiency of materials and reduce unit costs. En contraste, traditional production methods may increase labor and time costs, leading to higher prices for final products.

Transportation costs are also a cost component that cannot be ignored. Magnesium spraying materials usually need to be transported under specific conditions and may be affected by the transportation distance and mode of transportation. Por lo tanto, it is necessary to reasonably estimate the cost of the transportation link in the budget to obtain a more accurate cost forecast.

Finally, fluctuations in market demand will also affect the market price of magnesium spraying materials. When demand is high, prices may rise, while when the market supply exceeds demand, prices will fall.

magnesium gunning material uses

- High temperature furnace lining: used for high temperature furnaces in petrochemical and metallurgical industries.

- Steel production: as a protective layer for molten metal during the pouring of molten steel.

- Materiales refractarios: used to make refractory bricks and other high temperature resistant components.

- Foundry industry: used as a covering material for casting molds to provide a shell-proof effect.

- Mineral insulation materials: widely used in the insulation of power and electrical equipment.

Reseñas

Aún no hay reseñas.