Descripción

what is Refractory bauxite

Refractory bauxite is a bauxite with a high alumina content, mainly used to make refractory materials and produce aluminum. Its main component is alumina (Al2O3), generalmente entre 50% y 90%, with good refractoriness and slag resistance. Refractory bauxite maintains structural stability at high temperatures and is a key raw material for the production of high-alumina refractory bricks, calcinables refractarios, refractory mud and other materials. These materials are widely used in the lining of high-temperature equipment such as blast furnaces, hornos electricos, and heating furnaces to provide thermal insulation and refractory protection.

Además, Refractory bauxite is also used in the production of aluminum, extracting alumina through the Bayer process and then producing aluminum metal through electrolysis. Its versatility enables it to play an important role in many industrial fields such as metallurgy, industria química, and ceramics.

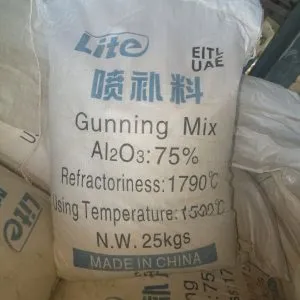

Otros productos amorfos

- Cemento refractario

- Refractarios de apisonamiento

- Plástico refractario

- Mortero refractario

- Agregado refractario

- Calcinable refractario

- Cenosfera

Parámetro técnico

| Artículo | Chemical analysis /% | densidad aparente (g/cm3) | Water absorption/% | ||||

| Al2O3 | Fe2o3 | TiO2 | CaO+MgO | R2O | |||

| AL-88 | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.15 | ≤4 |

| AL-85 | ≥85 | ≤1.8 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.10 | ≤4 |

| AL-80 | >80 | ≤2.0 | ≤4.0 | ≤0.5 | ≤0.5 | ≥2.90 | ≤5 |

| AL-70 | 70-80 | ≤2.0 | – | ≤0,6 | ≤0,6 | ≥2.75 | ≤5 |

| AL-60 | 60-70 | ≤2.0 | – | ≤0,6 | ≤0,6 | ≥2.65 | ≤6 |

| AL-50 | 50-60 | ≤2,5 | – | ≤0,6 | ≤0,6 | ≥2.45 | ≤6 |

What are the three types of bauxite?

Gibbsite or Trihydrate Bauxite:

Main component: gibbsite (Alabama(OH)₃). This type usually has a higher content of aluminum oxide (Al₂O₃) and is suitable for the production of alumina (bauxite refining process).

Boehmite or Monohydrate Bauxite:

Main component: diaspore (AlO(OH)). This type of bauxite contains some aluminum oxide, but requires special treatment during the refining process because diaspore requires higher temperatures and pressures to break down.

Kaolinitic or Diasporic Bauxite:

Main component: kaolinite (Al₂Si₂O₅(OH)₄) and gibbsite (AlO(OH)). This type usually has a lower content of aluminum oxide, but may contain more silicon and iron. Kaolinitic bauxite requires more complex processing to extract aluminum.

80% bauxite black 1-3mm

How to process bauxite into alumina?

- Ore preparation: Crushing and grinding – First, the bauxite is crushed and ground into fine particles to increase its surface area for subsequent chemical reactions.

- Bayer process: Digestion – Precipitation – Filtration

- Washing and drying: Wash the precipitated aluminum hydroxide with water to ensure that the residual sodium hydroxide and other impurities are removed; the washed aluminum hydroxide is dried and prepared for the next step of calcination.

- Calcination: Heating

- Product processing: The obtained alumina can be further processed as needed, such as crushing, screening, etc., to make products of different particle sizes and purities.

During the whole process, the sodium hydroxide solution will be recycled, reducing the consumption of chemicals and environmental impact. Al mismo tiempo, the insoluble impurities in the bauxite will form red mud, which needs to be properly treated to reduce environmental pollution.

Rotary kiln Refractory bauxite

4 uses of refractory bauxite

- High-alumina refractory bricks: Refractory bauxite is the main raw material for making high-alumina refractory bricks. These bricks are used for the lining of high-temperature furnaces, como los altos hornos, hornos de calentamiento, hornos electricos, etc., to provide structural stability and slag resistance at high temperatures.

- Refractory castables: Aggregates or powders used as refractory castables to improve the refractoriness and erosion resistance of the material.

- Refractory slurry: Used for masonry and repairing furnace linings, providing good bonding properties and refractoriness.

- Alumina production: Refractory bauxite is the main raw material for the production of alumina. Alumina is extracted from bauxite through the Bayer Process, and then aluminum metal is produced through the electrolytic process (Hall-Héroult Process).

85% yellow bauxite 1-3mm

Packaging and delivery

Bauxite packaging and delivery

Reseñas

Aún no hay reseñas.