Descripción

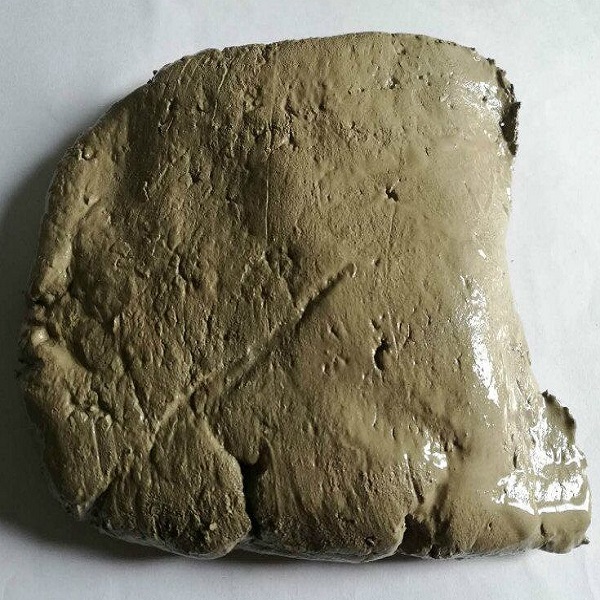

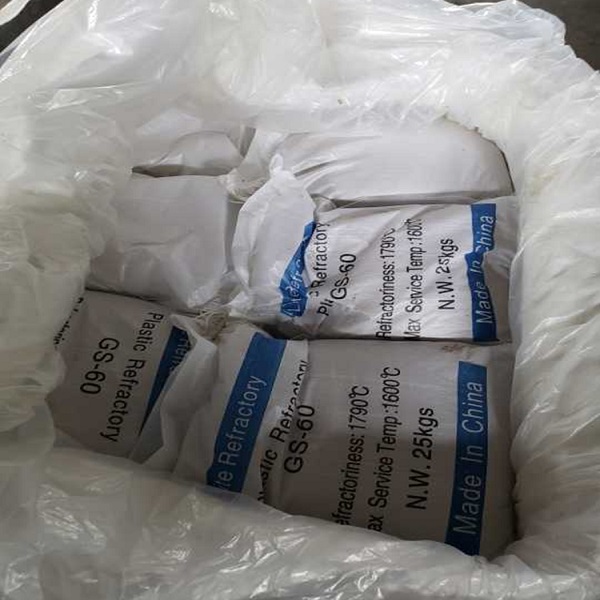

Breve descripción de los plásticos refractarios.

Los principales componentes de los plásticos refractarios son tipos específicos de resinas y cargas que, después de un procesamiento especial, Puede soportar altas temperaturas manteniendo una excelente resistencia mecánica y estabilidad.. Estos materiales normalmente pueden soportar temperaturas superiores 1000 grados Celsius sin deformación física significativa o degradación química.

Los principales componentes de los plásticos refractarios incluyen agregados como el clinker con alto contenido de alúmina., corundo, mullita y carburo de silicio. El aglutinante suele ser arcilla cruda o compuestos químicos., y los aditivos pueden incluir materiales expansivos como polvo de cianita., etc.. 65. Dependiendo del material, Los plásticos refractarios se pueden dividir en arcilla., alto contenido de alúmina, corundo, silicio, magnesio, carburo de cromo y silicio.

Otros productos refractarios sin forma

- material de pistola de magnesio

- Refractarios de apisonamiento

- Agregado refractario

- bauxita refractaria

- Calcinable refractario

- Cemento refractario

- Mortero refractario

Plástico refractario

Propiedades químicas de los plásticos refractarios.

| Nombre del material | Medio ácido (HCl, H2SO4) | Medio alcalino (NaOH) | disolvente orgánico (alcoholes, cetonas) | Temperatura de descomposición térmica (° C) | Resistencia a la tracción (MPA) |

| poliimida (PI) | Excelente | Bien | Bien | 400 | 90 |

| Politetrafluoroetileno (PTFE) | Excelente | Excelente | Excelente | 327 | 20 |

| Silicona (Silicona) | Bien | Medio | Excelente | 250 | 10 |

Cómo utilizar plástico refractario?

1. Preparación antes de la construcción.

2. Mezcla de materiales

3. tendido, clavar y embestir

4. Acabado de superficies y colocación de juntas de dilatación.

5. Mantenimiento

Clasificación de materiales plásticos refractarios.

- Plásticos de polietileno

- Plásticos de polipropileno

- Plásticos fluoroplásticos

- Plásticos de poliuretano

- Plásticos compuestos

Áreas de aplicación

- fundición de acero: Utilizado para la protección de partes clave de altos hornos., hornos de fabricación de acero, convertidores y otros equipos.

- industria de la construcción: Se utiliza para la producción de instalaciones de protección contra incendios, como muros cortafuegos., puertas cortafuegos, y paneles aislantes.

- Industria petroquímica: Se utiliza para la producción de componentes clave como catalizadores., intercambiadores de calor, y reactores.

- Industria energética: Se utiliza para la protección de piezas clave como las paredes de la caldera., chimeneas, y hornos en centrales térmicas, centrales nucleares, y otros lugares.

- Equipos termicos: Se utiliza para el revestimiento de equipos térmicos como calderas..

Reseñas

Aún no hay reseñas.