Descripción

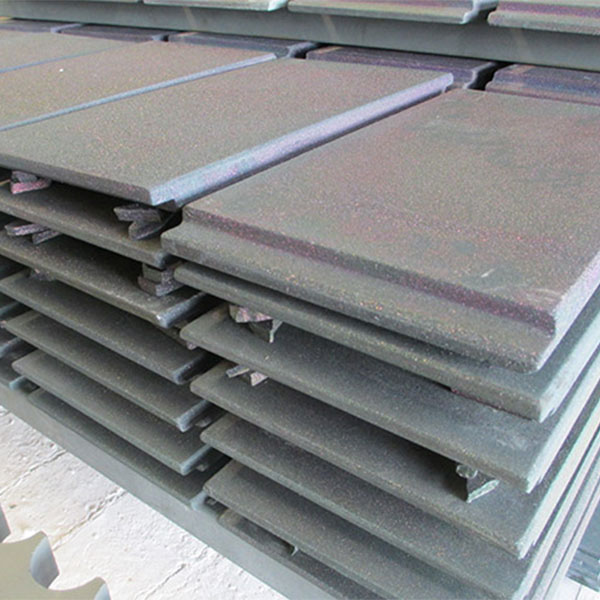

What is Silicon Carbide Shelf Board?

Silicon Carbide Shelf Board is a high temperature resistant material, mainly made of high purity silicon carbide combined with ultrafine powder.

placa de carburo de silicio, also known as silicon carbide ceramic plate, is a high-performance ceramic material known for its high hardness, alta resistencia al desgaste, high corrosion resistance and excellent high temperature resistance. In the ceramic firing process, silicon carbide plate is mainly used as a bearing platform and thermal insulation material to ensure that the ceramic sample will not be deformed or damaged during the firing process.

Other kiln furniture

![]()

Silicon carbide plate price

Chemical composition of silicon carbide slabs

| Elemento | effect |

|---|---|

| Sic | Main component, giving the material high hardness, high strength and high corrosion resistance |

| SiO2 | Exists on the crystal surface, possibly from oxidation during the refining process or after shutdown |

| Y | Dissolved in silicon carbide crystals or alloyed with metals |

Physical properties of silicon carbide slabs

| Propiedades físicas | describir |

|---|---|

| High temperature thermal conductivity | Suitable for high temperature environments, such as ceramic firing |

| High temperature load bearing | Able to bear weight at high temperature, suitable for sintering furnace |

| Resistance to rapid cooling and heating | It is not easy to crack during use and is suitable for environments with large temperature changes |

| Superficie lisa | No residue during use, keeping the product clean |

What causes silicon carbide shed panels to crack?

- Material brittleness: If the silicon carbide material itself is relatively brittle, with low tensile and flexural strength and poor impact strength, overall cracking may occur when it is acted upon by external forces.

- External factors: Sudden changes in temperature and humidity lead to different temperature changes on the outer surface and inside of the board, resulting in different shrinkage and expansion on the surface and inside, leading to cracking.

- Internal factors: The inhomogeneity of the internal structure of the plate, if there is a large difference, may cause stress concentration in local areas, thereby causing cracking.

- Difference in thermal expansion coefficient: If there is a significant difference in thermal expansion coefficient between the carbon substrate used in the silicon carbide shed panel and the silicon carbide material, cracking may occur due to thermal stress when the temperature changes.

- Improper processing and installation: Improper handling during processing and installation may cause holes or small cracks inside the bricks. These problems may affect the high-temperature performance of the silicon carbide shed panels and lead to cracking.

The difference between silicon carbide shed plate and filter plate

First of all,Silicon Carbide Shelf Board are mainly used in building ceramics, sanitary ceramics, daily ceramics, electric porcelain refractory materials and powder metallurgy sintering furnaces. It has good high-temperature thermal conductivity and high-temperature load-bearing properties, and can withstand the weight and heat in high-temperature environments.

Silicon carbide filter plates are mainly used for precision filtration and separation of various media, including the separation of gas-solid, liquid-solid, and gas-liquid. It has good filtration performance, can withstand high temperatures and strong corrosion, and is suitable for occasions requiring fine filtration.

Secondly, from the perspective of manufacturing process, silicon carbide shed panels are made of high-purity silicon carbide and ultra-fine powder, and are made through vibration molding and high-temperature sintering. Silicon carbide filter plates are microporous filter plates made through a specific process and may contain other additives to enhance their filtration performance.

Tablero de estante de carburo de silicio

Precauciones de uso

- Must be kept dry and away from moisture and moisture

- Avoid flat stacking and use upright arrangement.

- It should be placed beside the kiln to dry before use.

- The fired objects should be left to dry before being loaded into the kiln

- After glazing, the part of the product that comes into contact with the refractory board should be wiped clean.

- When constructing refractory panels, the refractory pillars should be kept vertical and straight to ensure uniform and smooth stress.

- The distance between building refractory boards should be greater than 15-20mm

- The user’s design of the firing curve should meet the conditions of normal operation and should not be rapid heating or cooling.

- Slow cooling should be used during cooling and avoid using cold air for rapid cooling.

- Be careful when moving down the kiln, avoid handling by hand in high temperatures, and avoid collisions.

Solicitud

Suitable for tunnel kilns, shuttle kilns, roller kilns, push plate kilns, etc..

Suitable for use in building ceramics, sanitary ceramics, daily ceramics, electric porcelain refractory materials and powder metallurgy sintering furnaces

Application of silicon carbide plate in ceramic sintering

- As a load-bearing platform: withstand high temperature and heavy pressure, maintain sample shape and size.

- As a heat-insulating material: reduce the impact of high temperature on equipment and surrounding materials.

Our other websites:https://www.lite-kilnrefractory.com/

Reseñas

Aún no hay reseñas.