Description

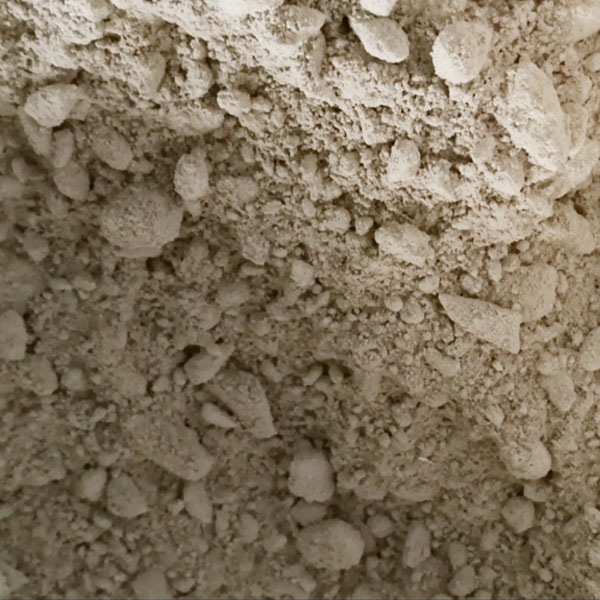

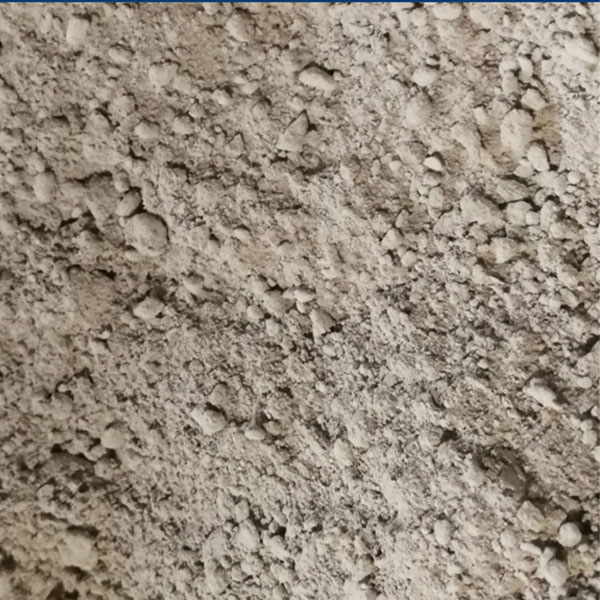

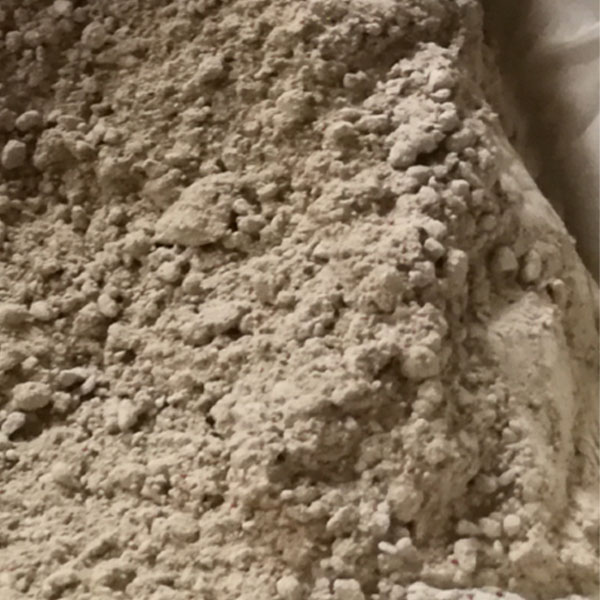

what is Clay castable?

Clay castables are made of refractory clay as the main material, with binders and additives added and mixed. They are resistant to high temperatures and thermal shocks, suitable for kiln linings and thermal equipment, easy to construct and stable in performance.

clay castable for sale

What is special about clay castables?

1. High temperature resistance

Clay castables can easily withstand high temperatures above 1600°C, making them an ideal choice for high temperature industries such as metallurgy and casting.

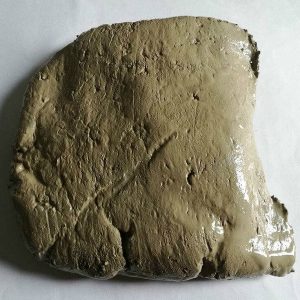

2. Good fluidity

It has excellent fluidity and can be easily poured into every corner of complex molds, ensuring a smooth surface after molding and reducing defects.

3. Strong wear resistance

Under high temperature and high pressure environments, clay castables exhibit excellent wear resistance, extend the service life of equipment, and reduce maintenance costs.

4. Résistance aux chocs thermiques

Even if it undergoes drastic temperature changes, it is not easy to crack, and is particularly suitable for industrial scenarios with frequent heating and cooling.

5. Environmentally friendly and safe

Using environmentally friendly raw materials, it is non-toxic and harmless during production and use, and meets the requirements of green manufacturing.

6. Flexible application

In addition to pouring, it can also be used by spraying, patching, etc., to adapt to different industrial needs and has strong versatility.

clay castable cement

The difference between clay castables and other castables

1. Composition difference

- Clay castable: refractory clay is the main raw material, Al2O2 content is low (usually 30-45%), and the cost is low.

- High-aluminum castable: mainly high-aluminum bauxite or corundum, high Al2O2 content (50-90%), better refractory performance.

- Corundum castable: mainly corundum, Al2O2 content ≥90%, excellent high temperature resistance and erosion resistance.

- Mullite castable: mainly mullite, Al2O2 content 60-75%, excellent thermal shock resistance and high temperature strength.

2. Application difference

- Clay castable: suitable for medium and low temperature kiln lining, hot air duct, flue, etc., low cost, economical and practical.

- High-aluminum castable: used for high temperature kilns, boiler linings, fours de chauffage, etc., with better high temperature resistance.

- Corundum castable: used for high temperature furnace lining, ladle, electric furnace, etc., with excellent corrosion resistance and high temperature resistance.

- Mullite castable: used for high temperature kiln furniture, hot air furnace, ceramic kiln, etc., with excellent thermal shock resistance.

Comparaison complète

- Clay castable: suitable for medium and low temperature and low corrosion environment, economical and practical.

- Other castables: suitable for high temperature, high corrosion, high strength demand scenes, better performance but higher cost.

where to buy clay castable

Avis

Il n'y a pas encore d'avis.