Description

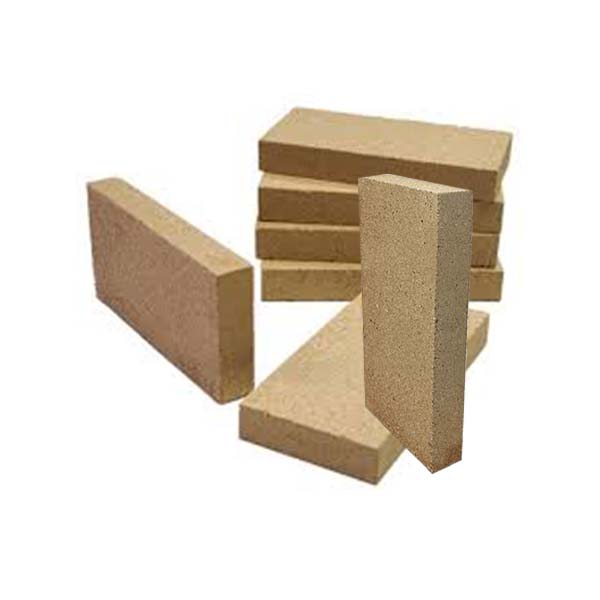

qu'est-ce que la brique réfractaire mince

La brique réfractaire mince est un matériau à haute température, principalement utilisé pour l'isolation thermique et les réfractaires dans des environnements à haute température tels que les parois des fours et les fours. Il est généralement composé de matières premières réfractaires et d'additifs par frittage à haute température.. C'est mince, habituellement environ 10 mm, et possède un excellent réfractaire, stabilité thermique et conductivité thermique. Les briques réfractaires minces peuvent réduire efficacement les pertes de chaleur et améliorer l'efficacité énergétique. Ils sont largement utilisés dans les équipements à haute température en métallurgie, céramique, verre et autres industries. Sa légèreté et sa haute résistance le rendent de plus en plus apprécié dans l'industrie moderne..

Indicateurs physiques et chimiques des briques réfractaires minces

| Nom de l'indicateur | définition | unité | Exigences générales |

|---|---|---|---|

| Perte au feu | Le pourcentage de perte de poids réfractaire à une certaine température | % | Ne doit pas dépasser 5% |

| Densité apparente | Le rapport volume/poids d'un matériau réfractaire à une certaine température | g/cm³ | 2.0-2.7 g/cm³ |

| Porosité apparente | Porosité visible sur la surface intérieure des matériaux réfractaires | % | Ci-dessous 24% |

| Résistance à la flexion | La résistance des matériaux réfractaires à la rupture sous une certaine charge | Mpa | 10-40 Mpa |

| Coefficient de dilatation linéaire | Le taux de variation du coefficient de dilatation linéaire des matériaux réfractaires pendant la dilatation et la contraction thermiques | 10^-6/℃ | 4.0×10^-6/℃ ou moins |

De Wikipédia: Brique réfractaire

Avantages de la brique réfractaire mince

- Résistance aux chocs thermiques: capable de résister à des changements rapides de température sans être endommagé

- Force: quand la température change rapidement, la force doit rester bonne

- Adaptabilité: convient aux matériaux de construction et aux matériaux de structure à haute température pour divers fours et équipements thermiques

- Durabilité: capable de résister à divers changements physiques et chimiques et aux effets mécaniques à des températures élevées

brique réfractaire mince à vendre

Quelle doit être l'épaisseur des briques réfractaires?

L'épaisseur des briques réfractaires dépend généralement de l'application spécifique et de l'environnement d'utilisation.. En général, l'épaisseur des briques réfractaires standards est généralement comprise entre 23 mm (à propos 1 pouce) et 76 mm (à propos 3 pouces). Voici quelques utilisations de différentes épaisseurs:

- 20-25 mm: Convient aux applications à charge plus légère de certaines parois de four à haute température.

- 30-50 mm: Convient à la plupart des fours et fours à haute température, offrant un bon effet d'isolation.

- Au-dessus de 50 mm: Convient aux fours industriels qui résistent à des chocs thermiques élevés et à des charges lourdes, tels que les fours de fusion ou les équipements pétrochimiques.

Principales utilisations des briques réfractaires minces

- Fours industriels: comme les fours à fer, fours sidérurgiques, fours à coke, etc..

- Fours de traitement thermique: utilisé dans le processus de traitement thermique des métaux.

- Revêtements de four: y compris les fours de fusion du verre, fours à ciment, etc..

brique réfractaire mince où acheter

Où acheter des briques réfractaires minces? Matériaux réfractaires Henan Lite vous accueille. Nous produisons des briques réfractaires de différentes tailles et spécifications. Bienvenue à nous consulter.

Avis

Il n'y a pas encore d'avis.