Keterangan

What is a Anchor Bricks?

Anchor bricks is a kind of brick used for the top wall of industrial furnace. It is embedded in the wall of refractory castable and can be used after baking at a certain temperature, thereby improving the overall performance of refractory castable. In terms of firing technology, it can be divided into two categories: semi-dry pressing molding and pouring vibration molding.

Batu bata tahan api populer lainnya

- Batu Bata Tahan Asam Tahan Api

- Batu Bata Silikon Mullite Tahan Api

- Batu Bata Silikon Karbida Tahan Api

- Batu bata silika

- AZS Brick

- Bata Corundum

- Batu bata alumina tinggi

- Batu bata tanah liat

- Bata Mullite

- Batu bata Magnesia

Batu Bata Jangkar Tahan Api

Technical indicators of brick anchor

| International code name | SK35 | SK36 | SK37 | SK38 | SK40 |

| Al2O3/% | ≥48 | ≥55 | ≥65 | ≥75 | ≥80 |

| Fe2O3/% | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| Sifat tahan api | ≥1750 °C | ≥1770 °C | ≥1790 °C | ≥1790 °C | ≥1790 °C |

| Porositas yang tampak | ≤22% | ≤22% | ≤23% | ≤23% | ≤21% |

| Cold crushing strength | ≥39Mpa | ≥44Mpa | ≥49Mpa | ≥54Mpa | ≥65Mpa |

| Sifat tahan api di bawah beban (0.2MPa) | ≥1420 °C | ≥1470°C | ≥1500 °C | ≥1520 °C | ≥1530 °C |

| Memanaskan Kembali Perubahan Linier (1500°C 2h) % | +0.1~ -0.4 *1450°C | +0.1~ -0.4 | +0.1~ -0.4 | +0.1~ -0.4 |

Anchor brick size

Common size

330mm

380mm

440mm

500mm

The thickness is generally around 100mm.

Ukuran

The size of the anchor brick should be determined according to the specific application scenario and the temperature range. Misalnya, the layout of the anchor brick should be determined according to the temperature range and frequency and the size of the wall area facing it, and should not be less than 6 pieces/m²3.

Brand

The brand of anchor brick is usually divided according to its physical and chemical indicators, such as LM-55, LM-65 and LM-75, where L and M are the Chinese pinyin initials of aluminum and anchor respectively, and the Arabic numerals following represent the mass percentage of aluminum oxide.

The role of anchor bricks

- Improve the integrity of the structure: Through reasonable arrangement and masonry, anchor bricks can connect the various parts tightly together to form a solid whole, thereby improving the stability and durability of the entire structure.

- Enhance refractory performance: The alumina content of high-quality anchor bricks can reach 75%. The load softening temperature of this type of brick body reaches 1550℃, yang merupakan produk batu bata tahan api yang sangat baik. Karena itu, anchor bricks can effectively resist high temperature and chemical corrosion and extend the service life of the furnace lining.

- Ensure construction quality: During masonry, it is necessary to carefully apply mud from both sides to prevent gas leakage; when approaching the anchor brick position, the bricks should be arranged in advance to determine the exact position, and the welding parts should be cleaned to ensure that the welding is firm. Selain itu, after the masonry is completed, the anchor hook needs to be inserted and the gap should be filled with refractory fiber felt to protect the anchor.

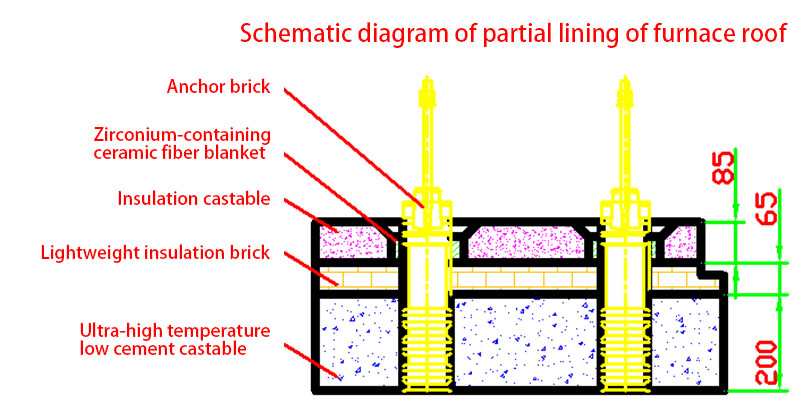

Schematic diagram of the function of anchor bricks

Steps and precautions for correct masonry of anchor bricks

1. Preparation work

- Cleaning the surface: Before masonry, the welding parts of the metal shell must be thoroughly cleaned, and all dust and impurities must be removed with a wire brush to ensure that the surface is clean and oil-free.

- Check anchor bricks: Carefully check each anchor brick to ensure that there are no cracks or other defects that affect strength. If there are any damaged bricks, they should be discarded immediately.

2. Apply mud

- Apply evenly: During masonry, apply mud evenly from both sides of the anchor brick to prevent gas leakage from the furnace top.

- Choose suitable mud: It is recommended to use air-hardening mud to prevent gas leakage in the furnace caused by mud shedding.

3. Masonry steps

- Pre-masonry: Before formal masonry, pre-masonry is carried out to ensure that the mortar joints meet the design requirements and the position of the hanging metal parts is correctly determined.

- Top masonry: Ensure the size of the masonry joints and carry out top masonry to ensure that the role of the hanging metal parts is fully utilized.

- Insert anchor hooks: Setelah batu bata jangkar dipasang, insert the anchor hooks and fill the gaps with refractory fiber felt and plug them tightly to provide a certain protection for the anchors.

4. Expansion joint design

- Leave expansion joints: Expansion joints should be properly left between the furnace body and the anchor bricks to accommodate thermal expansion.

- Design size: Design the size of the expansion joint according to the expansion coefficient of the anchor brick, and strictly follow the design size during masonry.

5. Quality control

- Check the masonry joints: Make sure the masonry joints are even and tight to avoid any looseness or gaps.

- Inspeksi rutin: During the masonry process, regularly check the installation of the anchor bricks to ensure that each step meets the standards.

6. Safety measures

- Wear protective equipment: Construction workers must wear necessary protective equipment, such as safety helmets, gloves, safety ropes, dll.. to ensure personal safety.

- Comply with safety regulations: Strictly abide by relevant safety regulations to ensure the safety of the construction site.

High alumina anchor bricks VS Clay anchor bricks

Area aplikasi

- Tungku industri

- Road and bridge paving

- Dyke and protective wall construction

Refractory Brick Production Line — Henan Lite

Ulasan

Belum ada ulasan.