Description

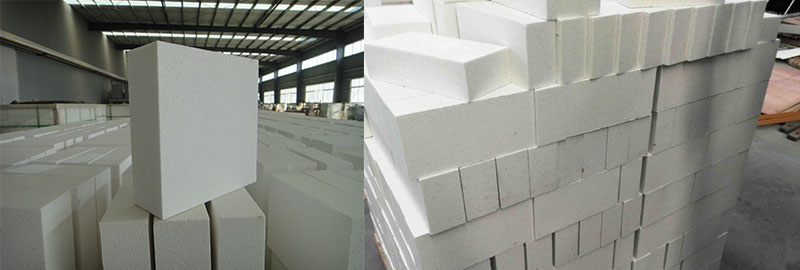

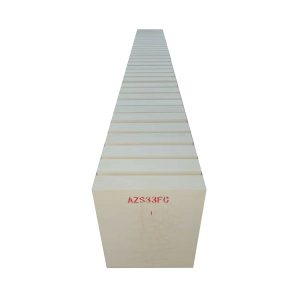

Corundum Brick Description

Corundum brick is a refractory material with alumina (Al2O3) as the main component, with a content of more than 90%. Due to its high melting point, high hardness and high strength, it is widely used in high-temperature kiln linings and kiln furniture.

Feature

(1)High temperature resistance

(2)High strength,high compression resistance

(3)Excellent thermal shock resistance

(4)High bulk density, good thermal conductivity

(5)Good wear resistance and acid

(6)alkali corrosion resistance

Corundum Brick

Regular size

- 230*114*65

- 250*123*65

- 171*113*65

- 230*65/55*114

- 230*114*65/55

- 230*114*65/45

- 230*114*20

- 230*57*65

- 230*150*75

- 230*150/120*75

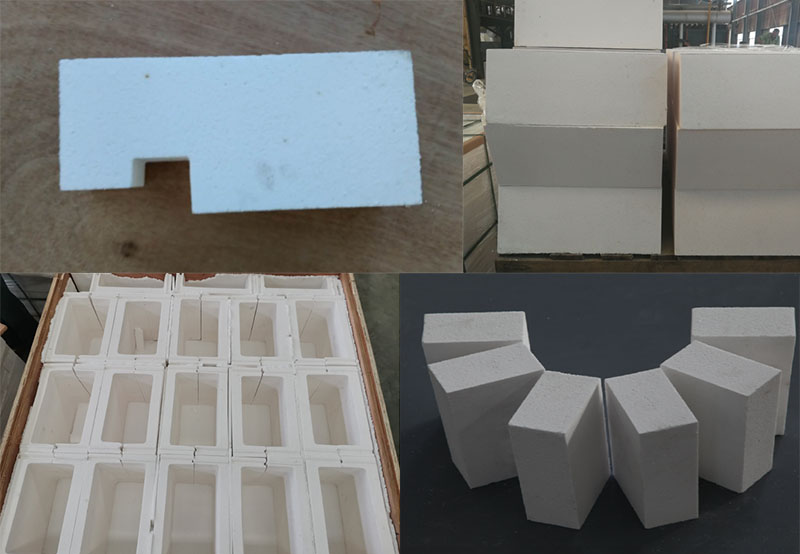

Customizable to any shape

Shape customization

Technical parameter

| Item | Corundum Brick 99 | Corundum Brick 90 | corundum mullite brick |

| Al2O3 % | ≥99 | ≥90 | ≥80 |

| SiO2 % | ≤0.2 | ≤8 | ≤18 |

| Fe2O3 % | ≤0.2 | ≤0.2 | ≤0.3 |

| Bulk Density g/cm3 | ≥3.2 | ≥3 | ≥2.8 |

| Apparent porosity % | ≤19 | ≤18 | ≤18 |

| Cold compressive strength MPa | ≥100 | ≥100 | ≥100 |

| (0.2Mpa,0.6%)Load softening began to temperature °C | ≥1700 | ≥1700 | ≥1700 |

From Wikipedia:Refractory

Production process

Sintering method: Use sintered alumina and phosphoric acid or other binders to make unburned corundum bricks.

Electrofusion method: High-purity alumina raw materials are melted and cast at a high temperature of more than 2000°C.

Henan LiTe Corundum Bricks Production Line

Production scale: 5 40 cubic shuttle kilns, 5 presses, automatic batching system, daily output of 80 tons, annual output of 20,000 tons

Production process: raw materials – crushing (0-1mm, 1-3mm, 3-5mm) – mixing – molding – drying (200℃) – sintering (1600℃-1700℃) – packaging

Production Line

Application fields of corundum bricks

1. In the steel industry;

2. In the non-ferrous smelting industry, the wear resistance and corrosion resistance of corundum bricks are significantly better than other bricks;

3. In the carbon black industry, on the carbon black reactor

4. In the petrochemical industry, in the gasification furnace of large and medium-sized fertilizer plants

Reviews

There are no reviews yet.