Description

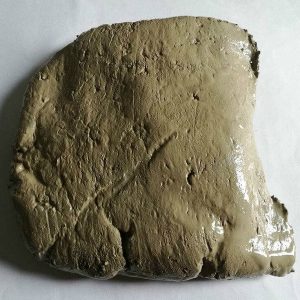

Refractory Aggregate Description

Refractory aggregate refers to the refractory granular material that acts as a skeleton in the particle size composition of the refractory material. They are made by calcining, crushing or artificial synthesis of various raw materials, and granular materials with a particle size greater than 0.088mm. Aggregate is the main material in unshaped refractory materials, generally accounting for 60%-75% of the total composition.

Other amorphous products

- Refractory cement

- Ramming refractories

- Refractory plastic

- Refractory mortar

- Refractory bauxite

- Refractory castable

Refractory aggregate ratio

- Large aggregate (5-10mm): 25-30%

- Medium aggregate (0.5-5mm): 25-30%

- Fine aggregate (<0.5mm): 20-25%

- Powder (such as high alumina powder, silica powder, etc.): 10-15%

- Binder (such as high alumina cement, sodium silicate, etc.): 3-7%

- Other additives (such as water reducer, expansion agent, etc.): 1-5%

Refractory aggregate bulk price

Technical Parameters

| Aggregate Type | Refractoriness(℃) | Bulk density(g/cm³) | Compressive strength(MPa) | Linear expansion coefficient(10⁻⁶/℃) | Thermal conductivity(W/m·K) | Slag resistance |

|---|---|---|---|---|---|---|

| High Alumina Aggregate | 1770 – 1850 | 2.6 – 2.9 | 30 – 80 | 6.5 – 7.5 | 1.2 – 1.8 | better |

| Clay aggregate | 1580 – 1700 | 2.3 – 2.5 | 10 – 30 | 5.0 – 6.0 | 0.8 – 1.2 | generally |

| Siliceous Aggregate | 1690 – 1730 | 1.8 – 2.2 | 10 – 30 | 11.0 – 12.0 | 1.3 – 1.7 | Poor |

| Magnesium Aggregate | 1750 – 1850 | 2.8 – 3.2 | 30 – 100 | 13.0 – 15.0 | 3.0 – 4.0 | excellent |

| Silicon carbide aggregate | 1700 – 1800 | 2.2 – 2.6 | 30 – 60 | 4.0 – 5.0 | 15.0 – 20.0 | excellent |

Advantages of refractory aggregates

High temperature performance:

- High refractoriness: aggregates can withstand extremely high temperatures without softening or deforming, ensuring the structural stability of the material at high temperatures.

- Slag resistance: Different types of aggregates (such as magnesium aggregates, high aluminum aggregates, etc.) have good slag resistance, can resist the erosion of slag, and extend the service life of the equipment.

Mechanical properties:

- Structural strength: Refractory aggregates provide the skeleton structure of the material, improve the compressive strength, flexural strength and wear resistance of the refractory material.

- Thermal shock stability: Appropriate aggregate ratio and selection can improve the thermal shock stability of the material and reduce material damage caused by temperature changes at high temperatures.

Construction performance:

- Flowability: By adjusting the grading and proportion of aggregates, the flowability of refractory materials can be improved, which is convenient for construction, especially in the construction of equipment linings with complex shapes.

- Construction flexibility: The use of aggregates enables refractory materials to be cast, vibrated, and pressed to meet different construction needs.

Cost-effectiveness:

- Rich resources: Many refractory aggregates (such as clay aggregates, siliceous aggregates, etc.) are widely available and relatively cheap, which reduces the production cost of refractory materials.

- Customizability: The proportion and selection of refractory aggregates can be adjusted according to the specific application environment and performance requirements to achieve a balance between cost and performance.

Thermal insulation performance:Lightweight aggregates: By using lightweight refractory aggregates, the bulk density of the material can be reduced, its thermal insulation performance can be improved, and the heat loss of the equipment can be reduced.

Chemical stability:Corrosion resistance: Refractory aggregates can resist chemical erosion, especially when in contact with slag, chemical gases or liquids at high temperatures, maintaining the stability of the material.

Refractory aggregate cost

Refractory aggregate uses

Provide structural strength:Refractory aggregates are the skeleton of refractory materials, providing the structural strength and mechanical properties of the materials. They maintain stability at high temperatures, resist the effects of thermal and mechanical stresses, and ensure that the refractory materials are not easily deformed or broken during use.

Improve refractory performance:Different refractory aggregates have different refractoriness and slag resistance. By selecting suitable aggregates, such as high-alumina aggregates, siliceous aggregates, magnesia aggregates, etc., the refractoriness, erosion resistance and wear resistance of refractory materials can be improved, so that refractory materials can show better performance in high temperature environments.

Improve construction performance:The particle size distribution and proportion of refractory aggregates directly affect the fluidity and construction performance of refractory materials. The appropriate aggregate ratio can ensure that the material has good fluidity and plasticity, facilitate pouring, vibration or pressing during construction, reduce construction difficulty and time, and improve construction quality.

Reviews

There are no reviews yet.