Description

Refractory castable Description

Refractory castables are a type of refractory material used in high temperature environments. They are made by mixing refractory aggregates, powders, binders and additives, casting and curing to form a solid lining. They have excellent high temperature performance and can withstand extreme high temperature conditions. The refractoriness is usually between 1580℃ and 1850℃. The construction flexibility of refractory castables makes them popular in the industry and suitable for furnaces, pipes and reactor linings of various complex shapes. They not only provide thermal insulation and refractory properties, but also resist slag, chemical erosion and mechanical wear, extending the service life of equipment.

During the application process, refractory castables can be customized according to different industrial needs. For example, in environments where slag resistance is required at high temperatures, high-aluminum castables or magnesium castables are widely used; while in occasions where wear resistance is required, such as circulating fluidized bed boilers, silicon carbide castables become the first choice. The construction process of refractory castables is relatively simple. They are formed by pouring, vibrating or pressing, and can be used after a certain curing time, which not only improves construction efficiency but also reduces equipment downtime. Their use not only improves the durability and safety of industrial equipment, but also provides higher efficiency and economic benefits for industrial production.

Other amorphous products

- Refractory cement

- Ramming refractories

- Refractory plastic

- Refractory mortar

- Refractory aggregate

- Refractory bauxite

Castable refractory formula

- Aggregate: such as high-alumina bauxite, silica, magnesia, etc.

- Powder: such as alumina powder, silica powder, etc.

- Binder: such as cement (high-alumina cement, silicate cement), phosphate, sodium silicate, etc.

- Additives: including water reducer, early strength agent, expansion agent, etc., used to improve the performance of the material.

Technical Parameter

| type | Refractoriness(℃) | Bulk density(g/cm³) | Compressive strength(MPa) | Line change rate(%) | Operating temperature(℃) | Slag resistance | Thermal shock stability |

|---|---|---|---|---|---|---|---|

| High alumina castable | 1770 – 1850 | 2.6 – 2.9 | 30 – 80 | ±0.1 – ±1.5 | 1350 – 1600 | better | generally |

| Clay castable | 1580 – 1700 | 2.3 – 2.5 | 10 – 30 | ±0.1 – ±1.0 | 1100 – 1400 | generally | Poor |

| Silicon castable | 1690 – 1730 | 1.8 – 2.2 | 10 – 30 | ±0.5 – ±1.5 | 1400 – 1600 | Poor | Poor |

| Magnesium castable | 1750 – 1850 | 2.8 – 3.2 | 30 – 100 | ±0.1 – ±1.5 | 1600 – 1800 | excellent | generally |

| Silicon carbide castable | 1700 – 1800 | 2.2 – 2.6 | 30 – 60 | ±0.1 – ±0.5 | 1400 – 1600 | excellent | excellent |

| Low cement castable | 1700 – 1850 | 2.5 – 2.8 | 40 – 90 | ±0.1 – ±1.0 | 1400 – 1700 | excellent | excellent |

| Cement-free castable | 1750 – 1900 | 2.5 – 3.0 | 50 – 120 | ±0.1 – ±0.5 | 1500 – 1800 | excellent | excellent |

Refractory castables HS Codes

- HS 6902.20.10 – Refractory castables mainly composed of alumina or alumina and silica.

- HS 6902.20.90 – Other refractory materials mainly composed of alumina or alumina and silica.

- HS 6902.90.10 – Refractory castables containing magnesia.

- HS 6902.90.90 – Other refractory materials not specified.

Refractory castable bulk price

Refractory castable uses

Furnace lining protection:

- Refractory castables are widely used in the lining of various high-temperature furnaces, such as blast furnaces, heating furnaces, converters, electric furnaces, etc. They provide structural stability at high temperatures and protect the furnace body from high temperature and slag erosion.

Wear-resistant lining:

- In circulating fluidized bed boilers (CFB) or other equipment requiring wear resistance, refractory castables are used as lining materials to resist the wear of solid particles and extend the service life of the equipment.

High Temperature Reactors and Vessels:

- Used for lining of high temperature containers such as chemical reactors, casting crucibles, melting furnaces, etc., providing thermal insulation, corrosion resistance and structural strength, ensuring the stability and safety of materials at high temperatures.

Flue and duct linings:

- Refractory castables can be used for lining flues and high-temperature pipes, providing thermal insulation, wear resistance and chemical corrosion resistance, reducing heat loss and improving pipe durability.

Repair and maintenance:

- Due to the ease of construction of refractory castables, it is often used to repair and maintain equipment with existing refractory damage. By pouring or spraying, damaged furnace linings, flues or other high-temperature parts can be quickly repaired to reduce equipment downtime.

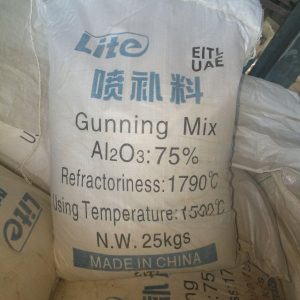

Casting material delivery packaging

Casting material delivery packaging

Company introduction

Henan LiTe Refractory Material Co.,Ltd is located in Zhengzhou Henan province, which is one of the main refractory production bases in China, specialized in refractory manufacture, Engineering Construction, Also new technology research & popularization and application for high temperature industrial furnace. The company possess the independent import & export certification, service the customers domestic & worldwide. Developed to be the technological manufacturer and service-type enterprise in the field of refractory for furnace engineering and technology.

FAQ

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

2. What’s your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What’s your payment terms?

We can accept 30% deposit, 70% balance before shipment.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

6. How about your company’s certification?

ISO9001 and Test Report,also we could apply other necessary certification.

Reviews

There are no reviews yet.