Description

What is refractory mortar?

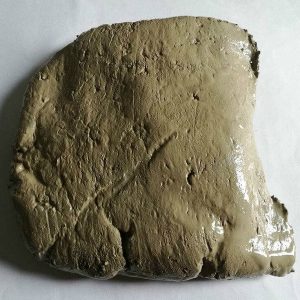

Refractory mortar is mainly made of refractory powder, admixtures and binders, and is also called “fire mud” or “jointing material”.

refractory brick mortar can not only be used as a mortar material, but also as a protective coating for walls.

Other refractory unshaped products

- Refractory bauxite

- Refractory aggregate

- Refractory cement

- Ramming refractories

- Refractory castable

- Refractory plastic

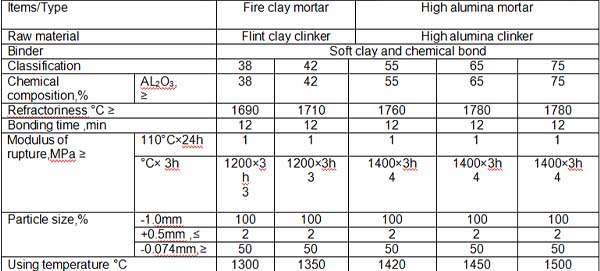

Properties of refractory mortar

Properties of refractory mortar

how to make refractory brick mortar

Material selection

12~16% silicate cement

10~15% powdered refractory mud

5% silica powder

20~30% quartz sand

30~50% river sand

The balance is water

Production steps

Mix the above materials evenly according to the proportion; add water and stir to the appropriate construction consistency

Precautions

Construction should be carried out in a suitable environment to avoid high or low temperature affecting the performance of mortar

Proper maintenance should be carried out after construction to ensure the strength and stability of the mortar

Refractory mortar

how to use refractory mortar

- Prepare refractory brick mortar, water, mixing bucket, agitator and other tools

- Mix refractory mortar and water evenly, and pay attention to controlling the viscosity

- Construction should be carried out in a dry, windless and rainless environment

- The surface needs to be cleaned before construction to ensure that it is dry, oil-free and free of debris

- Use professional tools for construction, and pay attention to the thickness, direction, density, etc. of the mortar coating

- After the construction is completed, the density, bonding strength, thickness and other indicators of the mortar need to be tested

- Avoid cracks after high temperature, and refractory aggregates and powders can be added

- Avoid moisture hardening, quick drying in the sun, freezing at negative temperatures, etc.

How long is the drying time of refractory mortar?

The drying time of refractory brick mortar usually depends on a number of factors, including ambient temperature, humidity, and the thickness of the mortar. In general, the initial drying time of refractory mortar at room temperature is about 24 hours, while complete drying and curing may take 7 to 14 days.

In practical applications, it is recommended to follow the specific drying guidelines provided by the manufacturer to ensure the performance and durability of the refractory brick mortar.

i buy refractory mortarWhat should I pay attention to

- When choosing refractory mortar, you should consider its fire resistance level, composition, scope of application and other factors to ensure that the selected product meets your specific needs.

- When purchasing, be sure to choose products produced by regular manufacturers, and pay attention to the production date, shelf life and certificate of conformity of the product.

- The use of refractory mortar needs to follow certain technical specifications. It is recommended to read the product manual in detail or consult a professional before use.

Henan Lite can meet your above needs

Application of refractory mortar

Generally used for laying and repairing masonry construction of hot blast stoves,boiler etc industrial furnace kiln.

Refractory Materials Exhibition in Saudi Arabia

Refractory Materials Exhibition in Saudi Arabia

Reviews

There are no reviews yet.