Description

Brief description of refractory plastics

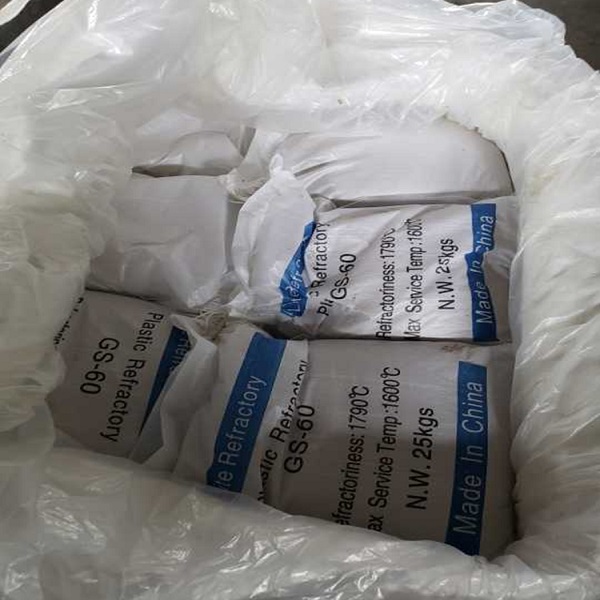

The main components of refractory plastics are specific types of resins and fillers that, after special processing, can withstand high temperatures while maintaining excellent mechanical strength and stability. These materials can usually withstand temperatures exceeding 1000 degrees Celsius without significant physical deformation or chemical degradation.

The main components of refractory plastics include aggregates such as high-alumina clinker, corundum, mullite and silicon carbide. The binder is usually raw clay or chemical composites, and admixtures may include expansive materials such as kyanite powder, etc. 65. Depending on the material, refractory plastics can be divided into clay, high-alumina, corundum, silicon, magnesium, chromium and silicon carbide.

Other refractory unshaped products

- magnesium gunning material

- Ramming refractories

- Refractory aggregate

- Refractory bauxite

- Refractory castable

- Refractory cement

- Refractory mortar

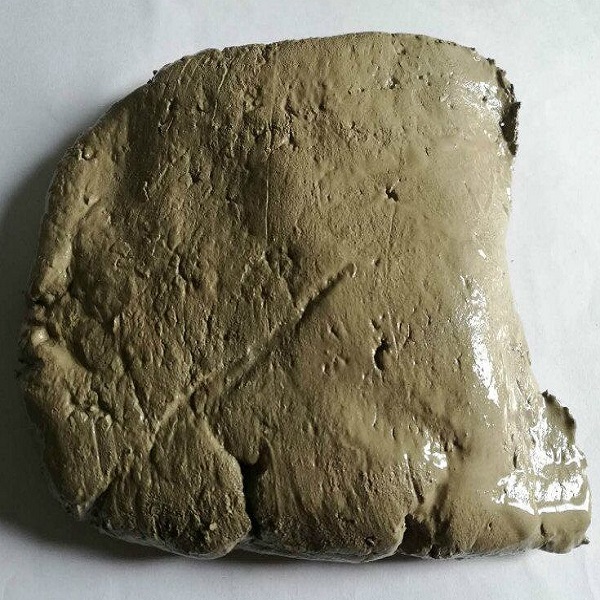

Refractory plastic

Chemical properties of refractory plastics

| Material name | Acidic medium (HCl, H2SO4) | Alkaline medium (NaOH) | Organic solvent (alcohols, ketones) | Thermal decomposition temperature (°C) | Tensile strength (MPa) |

| Polyimide (PI) | Excellent | Good | Good | 400 | 90 |

| Polytetrafluoroethylene (PTFE) | Excellent | Excellent | Excellent | 327 | 20 |

| Silicone (Silicone) | Good | Medium | Excellent | 250 | 10 |

How to use refractory plastic?

1. Preparation before construction

2. Mixing of materials

3. Laying, nailing and ramming

4. Surface finishing and setting of expansion joints

5. Maintenance

Classification of plastic refractory materials

- Polyethylene plastics

- Polypropylene plastics

- Fluoroplastic plastics

- Polyurethane plastics

- Composite plastics

Application areas

- Steel smelting: used for the protection of key parts of blast furnaces, steelmaking furnaces, converters and other equipment.

- Construction industry: used for the production of fire protection facilities such as fire walls, fire doors, and insulation boards.

- Petrochemical industry: used for the production of key components such as catalysts, heat exchangers, and reactors.

- Power industry: used for the protection of key parts such as boiler walls, flues, and furnaces in thermal power plants, nuclear power plants, and other places.

- Thermal equipment: used for the lining of thermal equipment such as boilers.

Reviews

There are no reviews yet.