- Home

- Steel industry

Steel industry

Solution

Introduction to electric arc furnace

The electric arc steelmaking furnace uses the high temperature of the electrode arc to make steel. The furnace body consists of a furnace cover, a furnace door, a steel tapping chute and a furnace body.

Main types of EAF furnace

- AC EAF: uses three-phase AC power to generate an arc in the furnace through three electrodes.

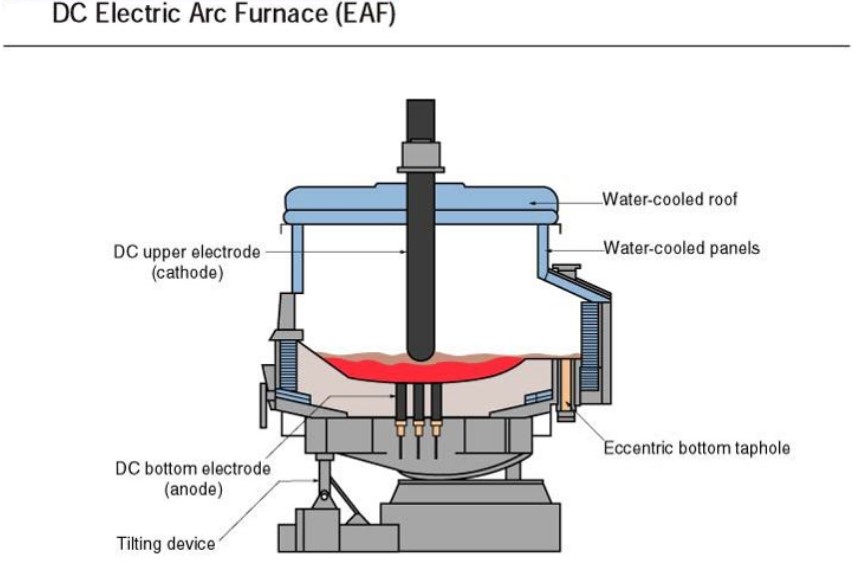

- DC EAF: uses DC power, and the arc is generated between one electrode and the furnace bottom, which is usually more efficient than AC furnace.

- Ultra-high power EAF: uses higher current density and power to improve melting speed and production efficiency.

Arc blast furnace structure

Furnace shell: usually cylindrical, lined with refractory materials to withstand high temperatures.

Electrode system: includes electrode lifting mechanism and electrode itself, electrode is usually made of graphite.

Furnace cover: can be opened or moved for charging and tapping.

Cooling system: prevents the furnace from overheating, usually water cooling is used.

Electrical equipment: including transformers, reactors, etc., to provide and control the electric energy required for the arc.

arc melting process

- Charging: Load scrap steel or other raw materials into the furnace. Scrap steel is the main raw material of the electric arc furnace.

- Arc ignition: Insert the electrode into the furnace and ignite the arc. The heat of the arc quickly heats the metal in the furnace.

- Melting: Under the continuous action of the arc, the metal begins to melt. At the same time, auxiliary materials such as lime and coke are added to adjust the composition and properties of the slag.

- Refining: After the metal is completely melted, refining operations such as desulfurization, dephosphorization, and deoxidation are carried out to improve the quality of the steel.

- Steeling: When the molten steel reaches the required temperature and chemical composition, open the furnace door and pour the molten steel into the ladle.

- Slag treatment: The treatment of slag is also very important, which can be recycled or treated to reduce environmental pollution.

arc melting furnace price

The price of an electric arc furnace is composed of many factors: including capacity, type, manufacturer, configuration, customization, region, new and old, etc.

Price reference range:

- Small electric arc furnace: RMB 100,000-1 million

- Medium electric arc furnace: RMB 1 million-10 million

- Large electric arc furnace: RMB 10 million or more

Differences between electric arc furnace and medium frequency furnace

The main differences between electric arc furnace and medium frequency furnace are size, steel purity, electricity used, thermal efficiency and productivity, and heating method.

- Size and steel purity: Electric arc furnace is large, generally more than 3 tons, suitable for large-scale enterprises, and the steel produced is purer. Medium frequency furnace is relatively small, suitable for small and medium-sized enterprises, but the steel produced has more impurities and high carbon content, so the purity is not as good as that of electric arc furnace.

- Electricity used: Electric arc furnace uses industrial frequency electricity, while medium frequency electric furnace uses medium frequency electricity.

- Thermal efficiency and productivity: Electric arc furnace has low thermal efficiency and productivity, cumbersome operation, and high energy consumption. In contrast, medium frequency furnace has high efficiency and thermal efficiency, more flexible operation, and low energy consumption.

- Heating method: Electric arc furnace is heated by arc generated by electrodes, while medium frequency furnace is heated by generating magnetic field. These two heating methods result in different temperatures and efficiencies.

Characteristics of electric arc furnace

- Steelmaking electric furnaces can more flexibly produce steel with specific properties and compositions, such as stainless steel, special steel, etc.

- The steelmaking electric furnace can easily adjust the furnace temperature and atmosphere in the furnace, making production more stable.

- Steelmaking electric furnaces have high production efficiency and low energy consumption, saving resources and costs.