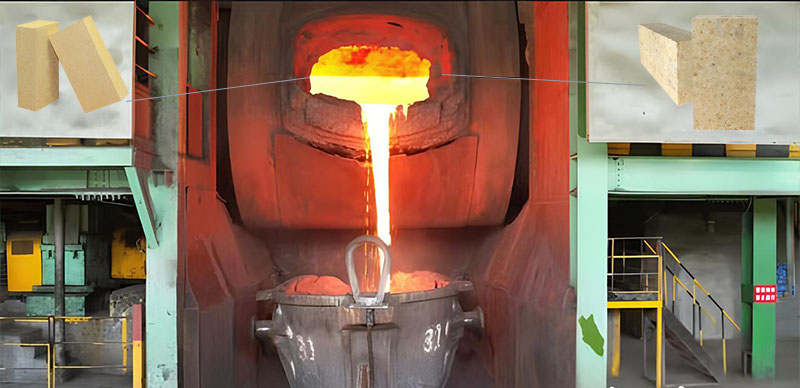

Hot face insulation bricks and cold face insulation bricks both play a very important role in high temperature environments. They have similarities and differences. Let us learn about them together!

Difference

| Hot face insulation bricks | Cold face insulation bricks | |

| Purpose and location | Directly in contact with high temperature flames or high temperature materials, usually used on the inside of high temperature environments such as furnace linings and smelting equipment. | It is mainly used to isolate the high temperature environment from the external environment and is usually installed on the outside or middle layer of the furnace or equipment to reduce heat loss. |

| Material | It is usually made of high refractory materials, such as high alumina bricks, silica bricks, magnesia alumina bricks, etc., and has extremely high refractoriness and erosion resistance. | Commonly used materials include aluminum silicate fiber, ceramic fiber, microporous calcium silicate, etc., emphasizing thermal insulation performance and light weight. |

| Refractoriness | Able to withstand extremely high temperatures, usually above 1500°C. | Although it is also fire-resistant, its main function is thermal insulation and its refractoriness is usually lower than that of hot surface insulation bricks. |

| Thermal insulation performance | Although it has thermal insulation properties, its main function is fire resistance and erosion resistance. | Specially designed for thermal insulation, with higher thermal insulation efficiency. |

| Mechanical strength | It has high mechanical strength to withstand mechanical stress at high temperatures. | Usually lighter and less mechanically strong, but strong enough to withstand the pressure of the insulation layer. |

hot face insulation bricks VS cold face insulation bricks

Common points

1. Same purpose: provide insulation and fire protection at high temperature, reduce heat loss and improve energy efficiency;

2. Complementary functions: They are generally used together to form a complete thermal insulation system. The difference is that the hot face insulation bricks protect the inside of the equipment, while the cold face insulation bricks protect the outside;

3. Installation and maintenance: Both must have expansion coefficients and regular inspections;

4. Material selection: Choose the appropriate insulation bricks according to physical properties and chemical composition;

5. Environmental protection: Both are made of inorganic materials and have little impact on the environment.

Hot face insulation bricks and cold face insulation bricks are hot-selling products of Henan Lite Refractory Materials. We can guarantee the quality of our products for you, and our after-sales service ensures that you have a perfect shopping experience with us.