Description

1.Brique réfractaire Description

Les briques Fire Clay sont des briques réfractaires fabriquées à partir de diverses matières premières, dont l'argile réfractaire., argile molle calcinée et argile molle. La teneur en alumine est généralement 30% -48% réfractaire à l'alumine. C'est un produit réfractaire faiblement acide qui peut résister à l'érosion des scories acides et des gaz acides., a de bonnes performances thermiques, et résiste au refroidissement rapide et aux températures élevées.

Autres briques réfractaires

- Briques à haute teneur en alumine

- Brique de mullite

- Brique de magnésie

- Brique de spinelle d'alumine de magnésie

- Brique de magnésie chromée

- Brique de carbone de magnésie

- Brique de corindon

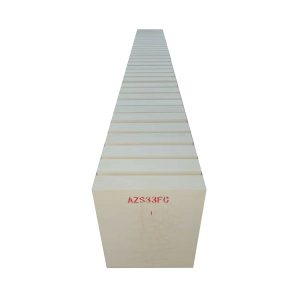

- Brique AZS

- Brique de silice

- Briques réfractaires en carbure de silicium

- Briques d'ancrage réfractaires

- Briques réfractaires de mullite de silicium

- Briques réfractaires résistantes aux acides

2.Brique en argile réfractaire

(1)Haute réfractarité

(2) Supportable à haute température

(3) Bonne résistance à la corrosion

(4) Bonne résistance à l'écaillage et à l'usure

(5) Bonne résistance aux chocs thermiques

(6)Haute résistance mécanique

(7) Bonne stabilité du volume à haute température.

3.Paramètre technique

| Série SK | SK30 | SK32 | SK34 | SK35 |

| AL2O3 | 30%-35% | 35%-38% | 38%-42% | 42%-50% |

| Fe2O3 /% | ≤ 3 | ≤ 3 | ≤ 3 | ≤ 2.5 |

| Résistance | ≥ 1690 ℃ | ≥ 1730℃ | ≥ 1750℃ | ≥ 1750℃ |

| BD/G/CM3 | 1.9-2.0 | 2.0-2.1 | 2.1-2.18 | 2.15-2.3 |

| Poids unitaire(230*114*65mm) | ≥ 3,35 kg | ≥ 3,55 kg | ≥ 3,65 kg | ≥ 3,75 kg |

| AP% | ≤ 26 | ≤ 24 | ≤ 24 | ≤ 22 |

| C.C.S. | ≥ 20Mpa | ≥ 25Mpa | ≥ 30Mpa | ≥ 35Mpa |

| R.U.L | ≥ 1250 ℃ | ≥ 1300 ℃ | ≥ 1350 ℃ | ≥ 1420 ℃ |

| R.L.C% | 0~ -0.5(1350℃ ,2h) | 0~ -0.3(1350℃ ,2h) | 0~ -0.4(1450℃ ,2h) | +0.1~ -0.4(1450℃ ,2h) |

De Wikipédia: Brique réfractaire

Avis

Il n'y a pas encore d'avis.