Description

High alumina bricks Description

High alumina bricks are mainly made of clinker of bauxite and other materials, mixed at high temperature, formed, dried and sintered. The Al2O3 content of high alumina bricks varies according to different ratios. The general content is stable at 48%-80%, the maximum alumina content can reach 90%, and the refractory temperature can reach 1770℃.It has good slag resistance and is used for lining of steelmaking electric furnaces, glass melting furnaces, cement rotary kilns, etc.

The production process of high alumina bricks is similar to that of clay bricks. The difference lies in the proportion of clinker in the raw materials, the firing temperature, and the degree of mechanization. The raw material bauxite is calcined, crushed, iron removed, mixed, pressed, dried, sintered at high temperature, and then packaged and stored. The sintering temperature of high alumina bricks is 1400-1500℃, and can be as high as 1700 degrees.

Common High Alumina refractory Brick sizes include: T3/T1/T2/T4/T5/T6…T19/T20 G1/G2/G3/G4/G5/G6

What is the hs code for high alumina bricks?

The H.S code for high alumina fire brick is 69022000.

High alumina refractory brick Technical Parameters

| International code name | SK35 | SK36 | SK37 | SK38 | SK40 |

| Al2O3/% | ≥48 | ≥55 | ≥65 | ≥75 | ≥80 |

| Fe2O3/% | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| Refractoriness | ≥1750 °C | ≥1770 °C | ≥1790 °C | ≥1790 °C | ≥1790 °C |

| Apparent porosity | ≤22% | ≤22% | ≤23% | ≤23% | ≤21% |

| Cold crushing strength | ≥39Mpa | ≥44Mpa | ≥49Mpa | ≥54Mpa | ≥65Mpa |

| Refractoriness under load (0.2MPa) | ≥1420 °C | ≥1470°C | ≥1500 °C | ≥1520 °C | ≥1530 °C |

| Reheating Linear Change (1500°C 2h) % | +0.1~ -0.4*1450°C | +0.1~ -0.4 | +0.1~ -0.4 | +0.1~-0.4 | +0.1~ -0.4 |

From Wikipedia:Refractory

Classification of high alumina fire bricks

- According to different contents: Grade III high alumina bricks (Al2O3: 48-65%), Grade II high alumina bricks (Al2O3: 65-75%), Grade I high alumina bricks (Al2O3: 75-80%), and special grade high alumina brick (Al2O3: ≥80%);

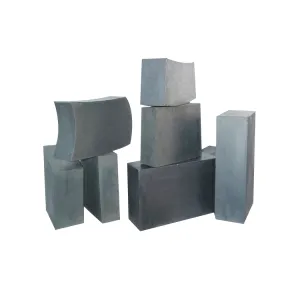

- According to shapes and sizes: knife-shaped, axe-shaped, wedge-shaped high alumina fire bricks, high alumina arch foot bricks, high alumina anchor bricks, etc.;

- Standard type: high alumina refractory bricks, special-shaped high alumina bricks, special-shaped alumina bricks;

- According to the type of kiln used: anti-stripping alumina brick for cement kilns, low creep high alumina bricks for hot blast furnaces, and phosphate alumina bricks for ceramsite/lithium oxide/zinc oxide rotary kilns;

high alumina bricks

Procurement standards for raw materials of high alumina bricks:

- Sk35/48%: the raw material is 60% high alumina clinker, with an iron content of less than 3.0%;

- Sk36/55%: the raw material is 65% high alumina clinker, with an iron content of less than 2.5%;

- Sk37/65%: the raw material is 75% high alumina clinker, with an iron content of less than 2.2%;

- Sk38/75%: the raw material is 85% high alumina clinker, with an iron content of less than 2.0%;

- Sk40/80%: the raw material is 88% high alumina clinker, with an iron content of less than 1.5%.

What is the price of high alumina fire bricks?

The price of high alumina bricks is divided according to grades. The price of standard bricks is relatively fixed. It will fluctuate with the price of raw materials and gas. The price of special-shaped bricks is not fixed; the price of standard alumina bricks ranges from 950-4500 yuan/ton.

What are high alumina refractory bricks used for?

Industrial kilns

Blast furnaces, hot blast furnaces, electric furnace roofs, blast furnaces, reverberatory furnaces, rotary kiln linings

High Alumina Brick can also be processed and manufactured into open-hearth heat storage checker bricks, plugs for pouring systems, nozzle bricks, etc. according to the needs of industrial kilns.

High alumina brick production workshop

The storage suggestions of high alumina refractory bricks are for your reference:

·Keep dry: High alumina fire bricks should be kept dry during storage and use to avoid moisture. Because alumina bricks are prone to falling off and cracking after being damp, affecting their performance. In an environment with high humidity, it is recommended to take moisture-proof measures, such as covering with moisture-proof cloth.

·Avoid acid and alkali erosion: High alumina bricks should avoid direct contact with acid and alkali substances to prevent erosion. During operation, neutral or weak alkaline materials should be used, and strong acid or strong alkali substances should be avoided.

·Control the use temperature range: High alumina refractory bricks have a certain use temperature range. When using, they should be operated according to the characteristics of the material and the specified temperature range to ensure that their performance is not affected.

·Regular inspection and maintenance: For high alumina refractory bricks that have been used, regular inspection and maintenance should be carried out, and the debris in the furnace should be cleaned in time to keep the furnace well ventilated to prevent crack expansion and slag erosion.

Reviews

There are no reviews yet.