One-stop service for refractory materials

—— Henan Lite

30 years of industry experience

About Us

Henan Lite Refractory Materials Co., Ltd. is a high-quality R&D and manufacturing enterprise in the field of refractory materials. It is one of the representatives of advanced manufacturers of refractory materials in China.

Our main products are high aluminum brick, AZS brick, refractory cement, ceramic fiber blanket, insulation brick, hollow shed board, etc. It is our honor to provide you with high quality refractory materials!

Hot Selling Product

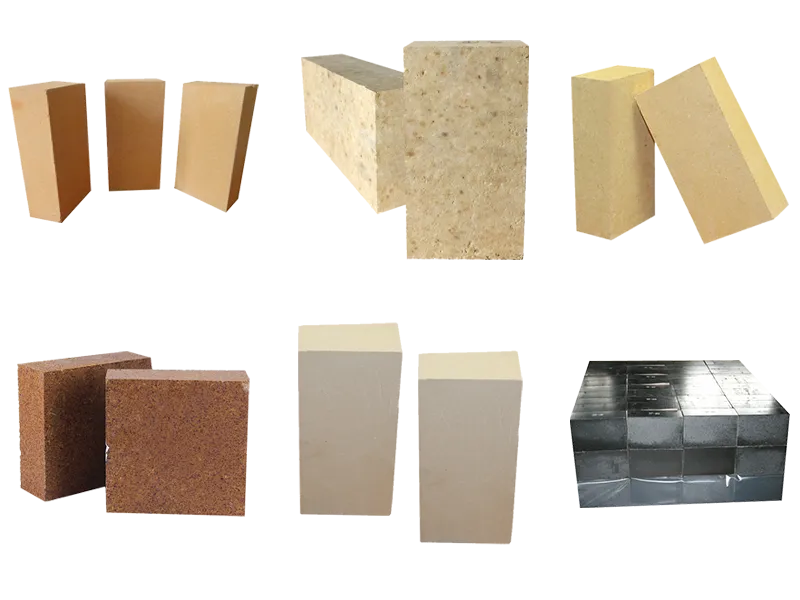

Refractory Bricks

Refractory bricks refer to masonry materials that retain their structural and chemical properties in a high temperature environment.

Generally made of refractory clay, silica or aluminum and other raw materials, it is widely used in high temperature furnaces in metallurgy, ceramics, chemical industry and construction fields.

Hot Selling Product

Unshaped Refractory Materials

Unshaped Refractory Materials are defined as materials that maintain stable performance in high-temperature environments, characterized by their lack of a fixed shape and typically existing in the form of powders or granules.

These materials are produced through processes such as molding, drying, and sintering during construction, finding extensive applications in high-temperature furnace bodies, linings, and other refractory structures within the metallurgy, chemical, and glass industries.

Hot Selling Product

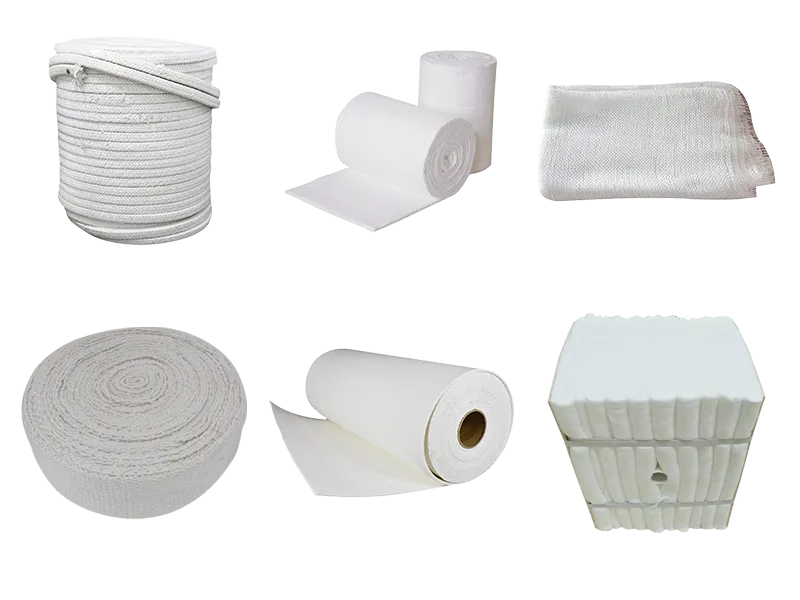

Ceramic fiber products

Ceramic fiber products refer to fiber products of various shapes, specifications and uses made of ceramic fiber as the main raw material. Such as ceramic fiber blanket, ceramic fiber board, ceramic fiber rope, ceramic fiber paper, ceramic fiber cloth, ceramic fiber felt, ceramic fiber module, etc.

Its performance characteristics: good high temperature resistance, lightweight structure, low heat capacity and low thermal conductivity, etc., commonly used in high temperature furnace linings, molten metal filters, aerospace fields, environmental protection fields, etc.

Hot Selling Product

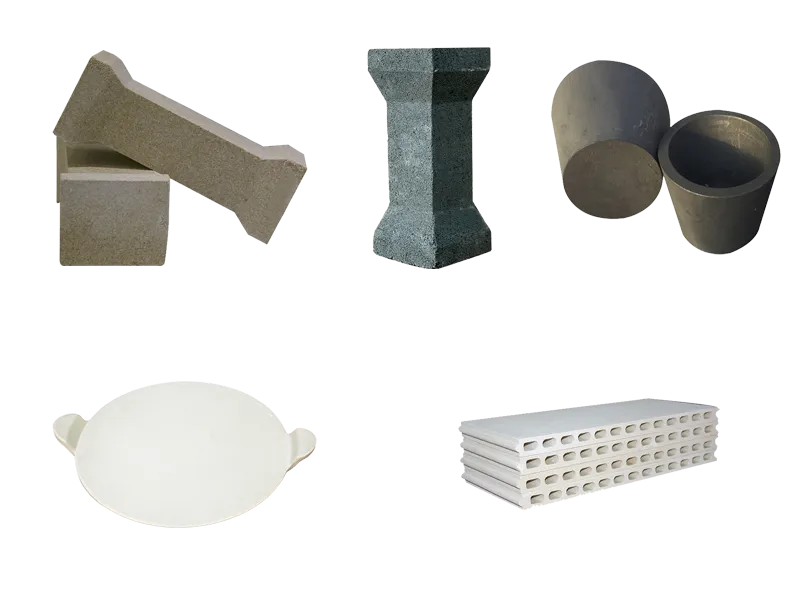

Kiln Furniture

Kiln furniture is a tool made of refractory clay that serves as a spacer, supporter, cushion, and protector for the blanks during the firing process.

It has good thermal shock resistance and mechanical properties at room and high temperatures, good thermal conductivity and air permeability, high load softening temperature, and refractoriness.

Features

Why choose us

- One-stop purchasing service

- Service provider that provides solutions

- 30 years+ industry experience

- Exported to 100+ countries around the world

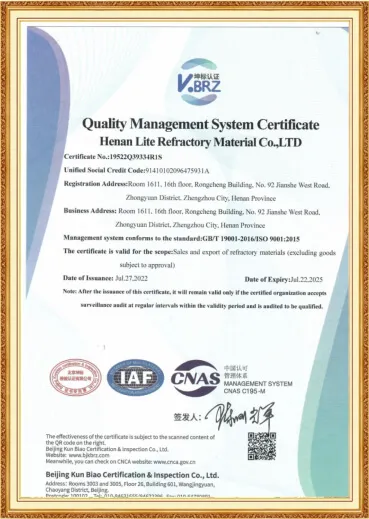

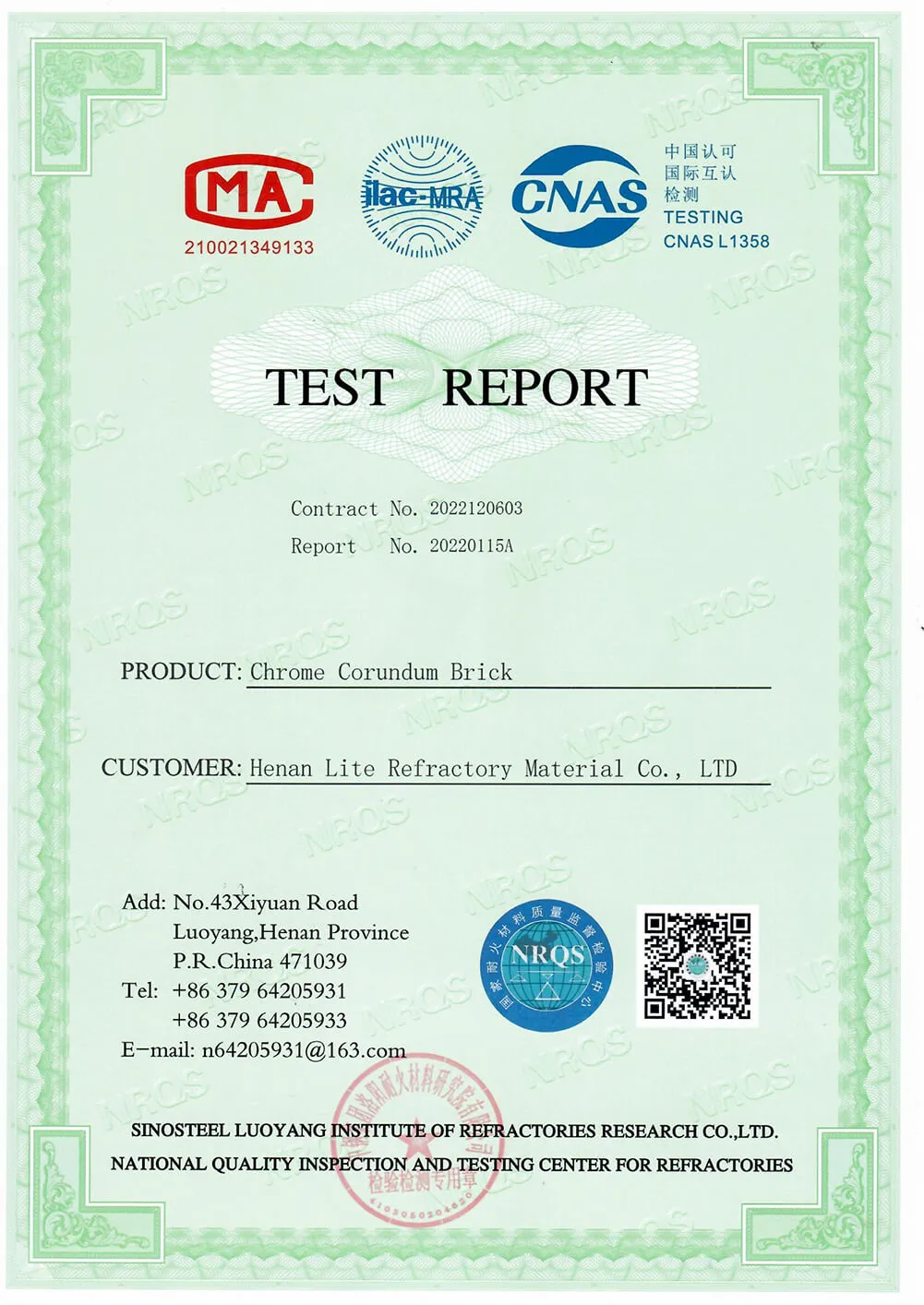

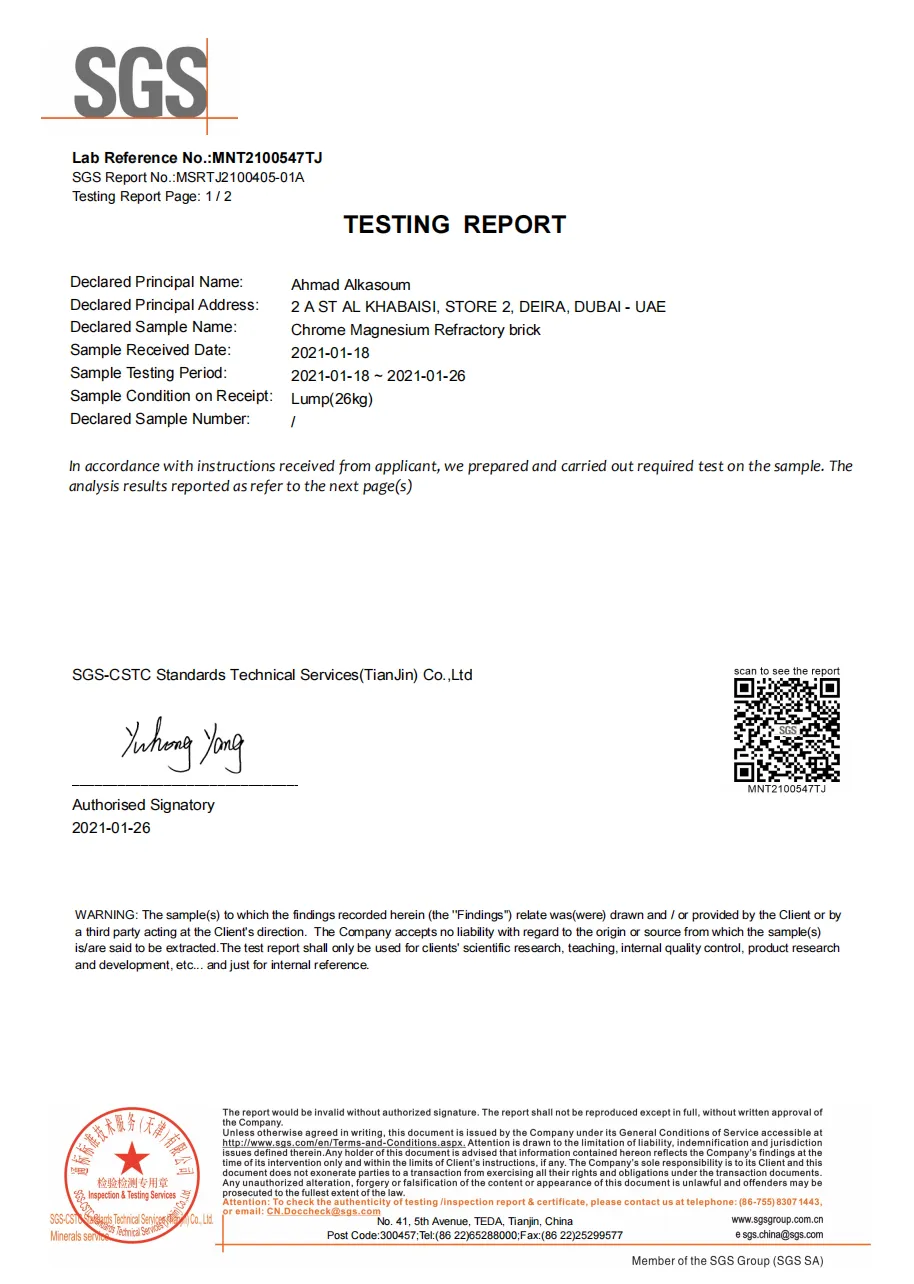

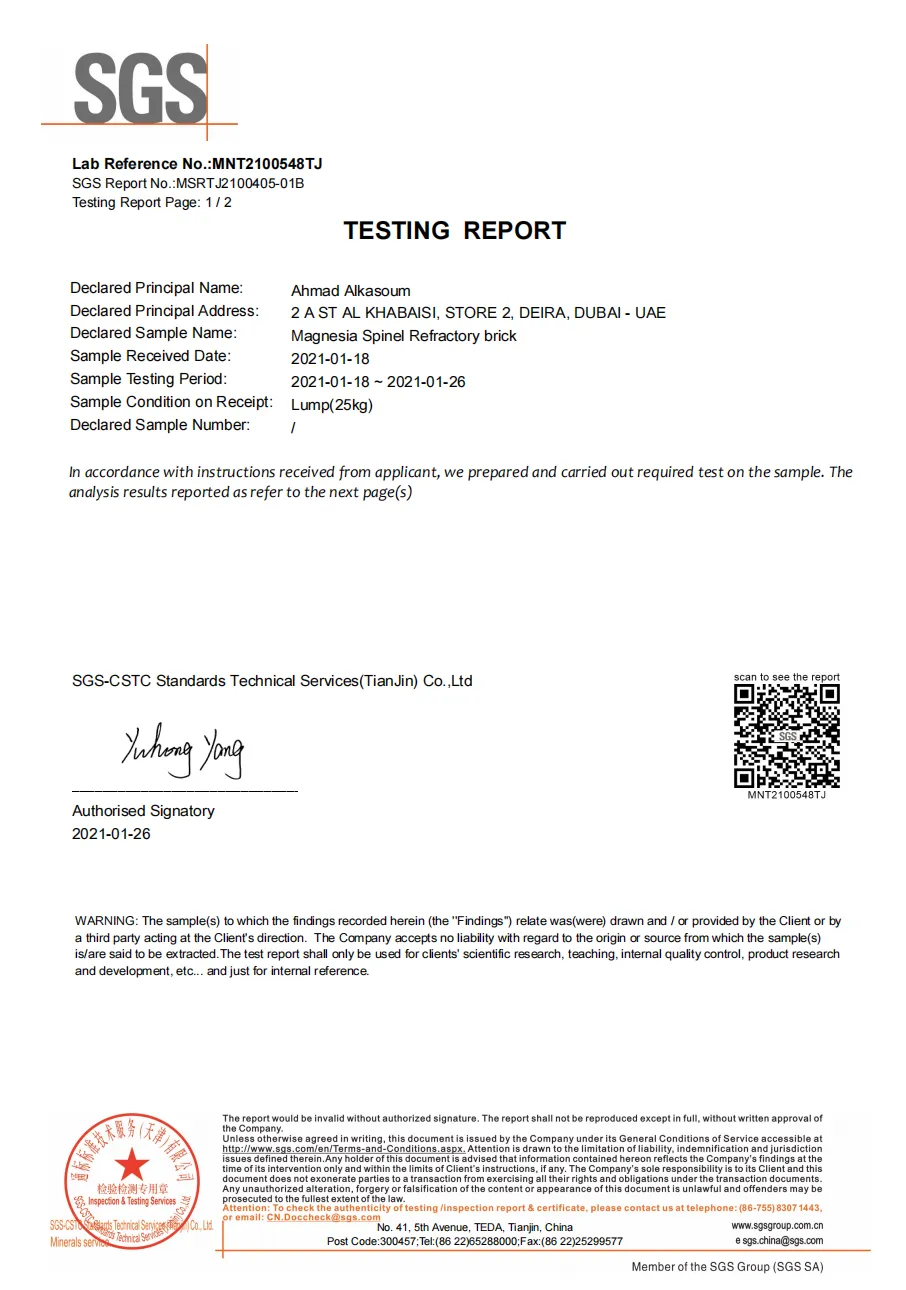

certification

Authoritative certification

FAQ

Frequently Asked Question

A: CIF, if you need other modes of transportation, you can negotiate with our sales staff.

Answer: Yes, our production scale can be said to be second to none in the material circle, whether it is product quality, or other services, are incomparable.

A: Provide samples, if you need samples, the service team can fully meet your needs.

A: Yes, we have our own factory workshop, every day to produce a large number of resistant products, you need at any time, we are ready to ship, shorten the time to receive products.

A: We can supply you with any quantity according to your needs.

BLOG

our latest news & blog

clients testimonials

What's Our Clients Talk About Our Work

Your the best LynnWe are installing tomorrow and firing tomorrow night.

very happy to work with this company. though order was not so big, very big was attention to me. Patient and comfortable in communication willing to help and give detailed info where needed.

Customers from the United Kingdom

I cannot thank Chloe enough for her thoroughness and thoughfulness, as well as being such a sweet and lovely person! Again, I really appreciate the way the technicians were able to manufacture my custom products. Everything was packaged superbly and arrived in perfect condition.

Get In touch

Have Questions?

Please give us a call, drop us an email or fill out the contactform and we’ll get back to you.